How to simplify the control architecture of cartesian coordinate robots

By Barry Weller, product manager at Mitsubishi Electric

In order to remain competitive, it is generally accepted that industries should adopt lean manufacturing strategies to improve process efficiency.

A key action can be to reduce part count, that is to say the number of components in an assembly or system. This is particularly challenging when it comes to highly accurate cartesian coordinate (linear) motion applications.

In these cases, machine builders would often need to use both PLCs and computer numerical controllers (CNCs) in order to fully manage movement within the machine – until now.

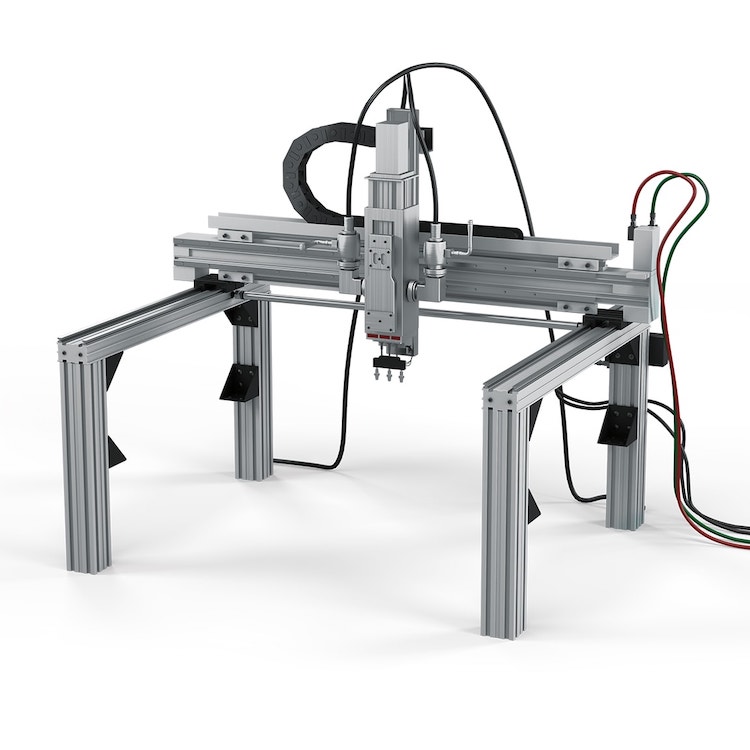

Cartesian coordinate robots are widely used to automate machine functions such as mechanical, laser or plasma cutting – quickly delivering highquality items that are consistent and can be highly customised.

While a cartesian coordinate robot and a CNC (computer numerical control) machine are not necessarily the same thing, the motion of both is typically controlled by a CNC system.

The reason for this lies in the simplicity of programming motion control trajectories with computer numerical controllers and their G-Code language.

This programming language is distinct because it instructs machines on where and how to move based on computer-aided design/manufacturing (CAD/CAM) images and files.

G-code reads CAD/CAM files for the intended end products and converts them into trajectories and directions for CNC servo drives within the cartesian coordinate robot.

As a result, highly accurate, precise and reproducible movements can create even the most complicated and unusual 2D shapes and contours.

While CNC solutions work well as robot controllers, they cannot monitor and guide other components, such as solenoid valves, clamps and air hoses – to do so, the unit needs a PLC.

This could theoretically handle tight tool control and feedback for all the different automation parts, eliminating the need for CNC systems.

However, writing motion control code for cartesian coordinate robots with any of the five PLC languages would be quite challenging. Consequently, machine builders and users need to use these two different control systems for one machine.

This solution is however far from ideal: additional hardware will only increase the total cost of ownership for the machine and can also affect build / commissioning time.

In fact, two separate control units need to share time-critical information, increasing potential cycle times and increasing the likelihood of communication jitters that could desynchronise PLC- and CNC-based processes on the same machine.

A holistic approach to motion programming, control and feedback

To address these issues, factory automation component and system manufacturers are beginning to invest in motion control technologies that cross the boundaries between PLCs and CNC systems to create integrated machine controllers that combine key functions from both solutions.

A good example is Mitsubishi Electric’s MELSEC iQ-R motion controller and its G-Code add-on library. By choosing this solution, machine builders can use general-purpose servos and MELSEC iQ-R series PLCs to implement CNC capabilities, if needed, by installing the G-Code library.

This allows the programming of highly accurate complex cutting trajectories and profiles in G-Code without the need for computer numerical controllers.

More precisely, the add-on function helps the system to follow PLC-specific programming instructions, such as Motion SFCs (sequential function charts), as well as automatically generate and read motion profiles from CAD/CAM files.

The G-Code programmes, available in text format, can be edited easily on Mitsubishi Electric’s HMIs or with any generic editor.

By eliminating the need for separate PLC and CNC component hardware, the MELSEC iQ-R system can synchronise the different processes within one machine and reduce cycle times.

Furthermore, the possibility to use one single solution for various applications, including CNC machining and easily switch between them allows machine builders to use it to control a complete production line.

As a result, businesses can benefit from a highly flexible, fast and cost-effective system that truly streamlines their industrial processes whilst delivering quality and consistency.