Veo Robotics launches new solution that aims to make all industrial robots collaborative

Startup company Veo Robotics has launched its first commercially available product – FreeMove, a hardware-and-software solution which is said to be able to transform standard or traditional industrial robots into collaborative robots.

Traditionally, industrial robotic arms have been treated with some trepidation, and are still always caged off or otherwise kept separate from human workers.

Their size, weight and speed make industrial robotic arms potentially very dangerous, and without any programming about human workers and how to avoid endangering them, they can be lethal.

Collaborative robots are a new category of robotic arms which are specifically designed and programmed to be used by human workers as though they were power tools.

Humans can work in close proximity to collaborative robots and handle them directly.

Collaborative robots are a recognised as distinct by the International Standards Organisation. The cobot market is still quite small compared to the standard robot arm market, but it’s growing fast.

What Veo Robotics is aiming to do is sort of reconfigure or reprogram any standard industrial robotic arm to be operable by a human worker in close proximity or direct contact, mush like a collaborative robot.

The company has been working on developing its product for quite some time, and Robotics and Automation News interviewed one of the company’s executives a while ago.

Now, in launching FreeMove, Veo says it has released a “safety-ratable, production-ready vision system for safe human-robot interaction”.

In a blog post by the CEO, Patrick Sobalvarro, and other executives, the company says: “The Veo FreeMove system gives manufacturing engineers the freedom to combine the strength, precision, and speed of standard industrial robots with the ingenuity, judgment, and dexterity of humans.”

It adds: “By making it possible for standard industrial robots to respond safely to nearby humans, Veo FreeMove plays to the strengths of both humans and robots. Doing so increases worker productivity, improves ergonomics, and reduces engineering and capital equipment costs.”

Veo says that, because FreeMove will override the robot program as necessary to safely slow and stop, it allows for the design of ISO 10218 SSM-compliant applications and workcells.

Additionally, because the Sensors and Engine have continuous registration and health monitoring systems, any fault will safely stop the robot, it says.

The Veo FreeMove system is compliant with ISO 13849 (Safety of machinery – Safety-related parts of control systems), meets the requirements of PL=d, structure category 3, and consists of:

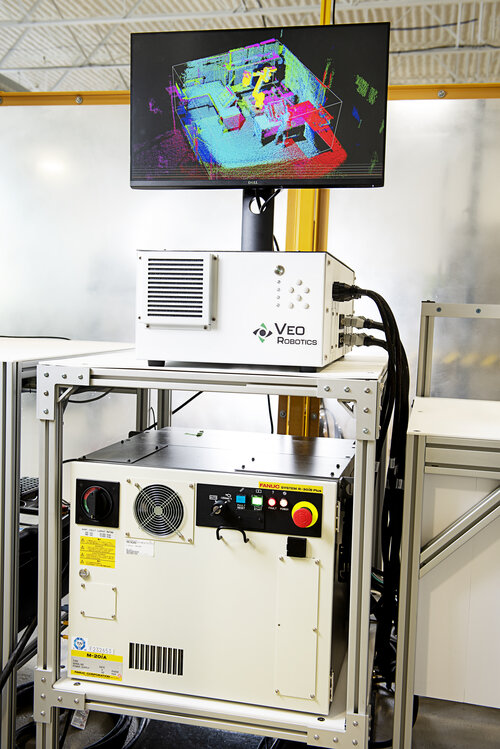

- FreeMove Sensors: custom, 3D time-of-flight sensors that are mounted on the workcell periphery to cover the volume of the safeguarded space.

- FreeMove Engine: a high-performance, dual-channel architecture computing platform that runs fail-safe software that processes image data from the sensors and implements Speed & Separation Monitoring (per ISO 15066).

- FreeMove Studio: a software suite for self-service configuration and real-time visualization of the sensors and FreeMove Engine data.