Digital Visual Management: Integration of Human-Centricity and Automation

By Nicola Olivetti, Lean and Industry 4.0 Program Director, iObeya

Recently, a leading industrial journalist asked for an explanation about the pragmatic integration of human-centricity and automation. Below are my responses.

Question: How can you preserve a human-centric approach to collegial work in a highly automated environment?

Answer: Companies with an authentic Lean culture leverage automation to expand the scope of teams by granting real-time access to valuable information. This allows for important activity and relevant people (experts, partners, suppliers, customers) to co-operate in a horizontal and agile manner.

Management of “traditional,” non-Lean companies with a top-down specialist culture, believes that teams in the field are fundamentally unable to make decisions. This use of automation is designed to reduce teams’ ability to maneuver and control execution. Ultimately, these manufacturers reduce headcount until they can fully move execution to machines.

The root cause of these seemingly disparate conditions is empowerment. Power is nothing more than deciding and executing. Companies embracing authentic Lean principles, highly value operational empowerment as both a way to respect team members and build a competitive advantage through rapid response, learning, and motivated workforce.

Q. How have Artificial Intelligence (AI), Industrial Internet of Things (IIoT), Augmented Reality (AR), and other Industry 4.0 technologies impacted workforce engagement?

A. “Smart factories” are the “brain” of the factory. When the “interesting” part of a job is taken away from the workforce, there is an obvious loss in ownership. This kind of transfer should be carried out only if the expected business impact is overwhelmingly important. Until that stage, the “smart” part of the job should stay in the field.

Change management plays a vital role in helping the workforce transition to a new set of jobs; teams change a work paradigm and look at every activity from a new perspective.

Q. How can management leverage these technologies while safeguarding team cohesion?

A. Management should develop a deep knowledge of operational processes from the field and constantly collect feedback from workers. They should also avoid any automation until fully mastering key processes.

It is recommended that management automate one or several process steps to test what works best. This fast-learning cycle allows a return to the previous state, if the test fails. If this proof-of-concept test passes, management implements a thorough deployment plan, with at least 30 percent of resources dedicated to change management. First think people and processes, then technology.

Q. How do Millennials adapt to automation in a work environment?

A. Millennials are already used to collaborative technologies; it is part of their everyday life. When joining a company, many Millennials are surprised to see that the technology they are accustomed to using in their daily lives is not replicated in the work environment. There is a clear generational gap in terms of technology adoption.

Q. What does a human-centric workforce do to balance human interaction and robotic automation?

A. A human-centric workforce will focus on process improvement and carry it out through strong teamwork. This is too complex to be done by artificial intelligence. Human-centricity will be preserved because humans will keep the control of process and system design.

AI and robotics will increase their performances, but for very specialized tasks or process steps, without a holistic vantage point.

Human-centricity and automation impacts

Q. How is Digital Visual Management (DVM) uniquely positioned to bridge the gap between automation and a human-centric approach?

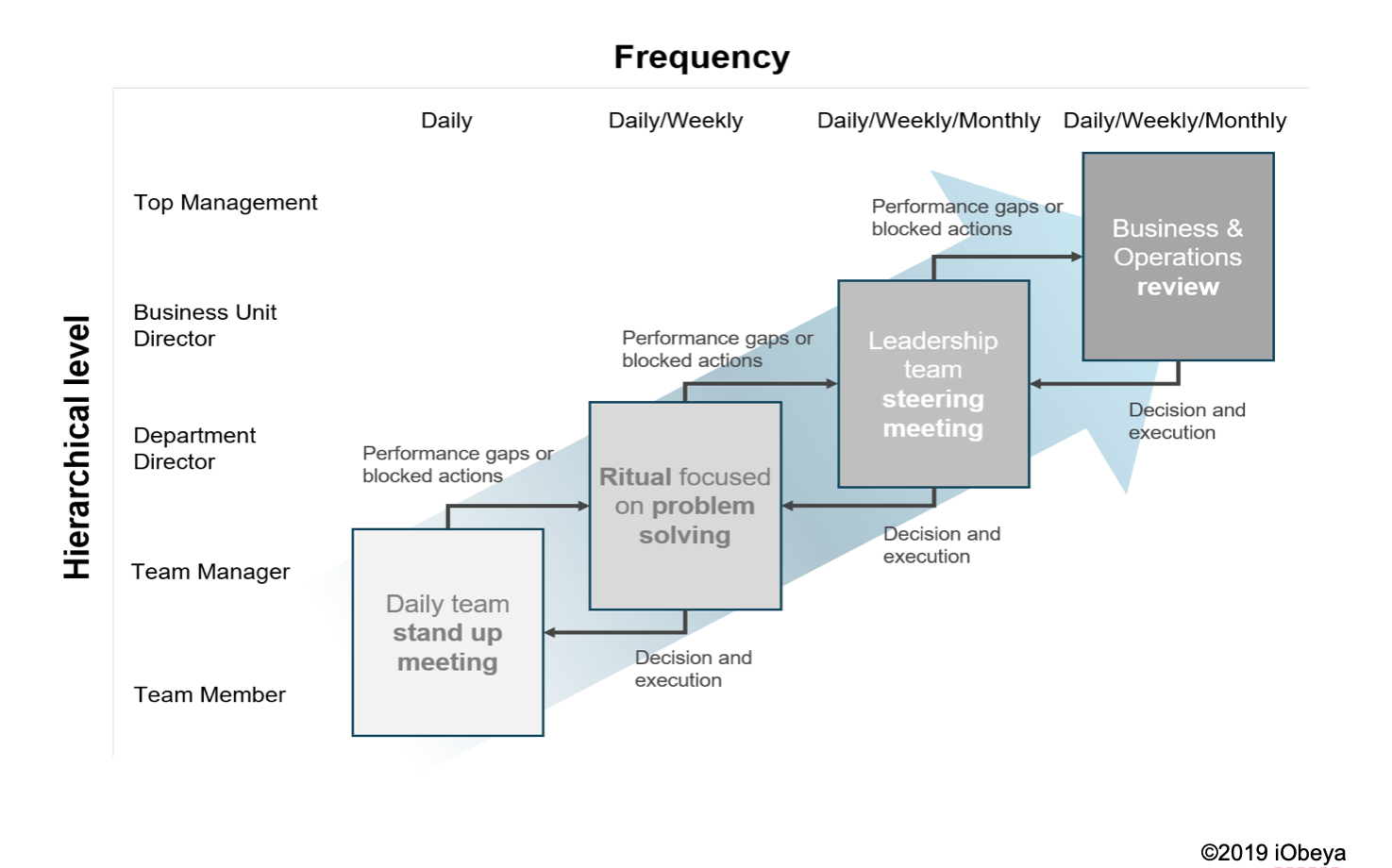

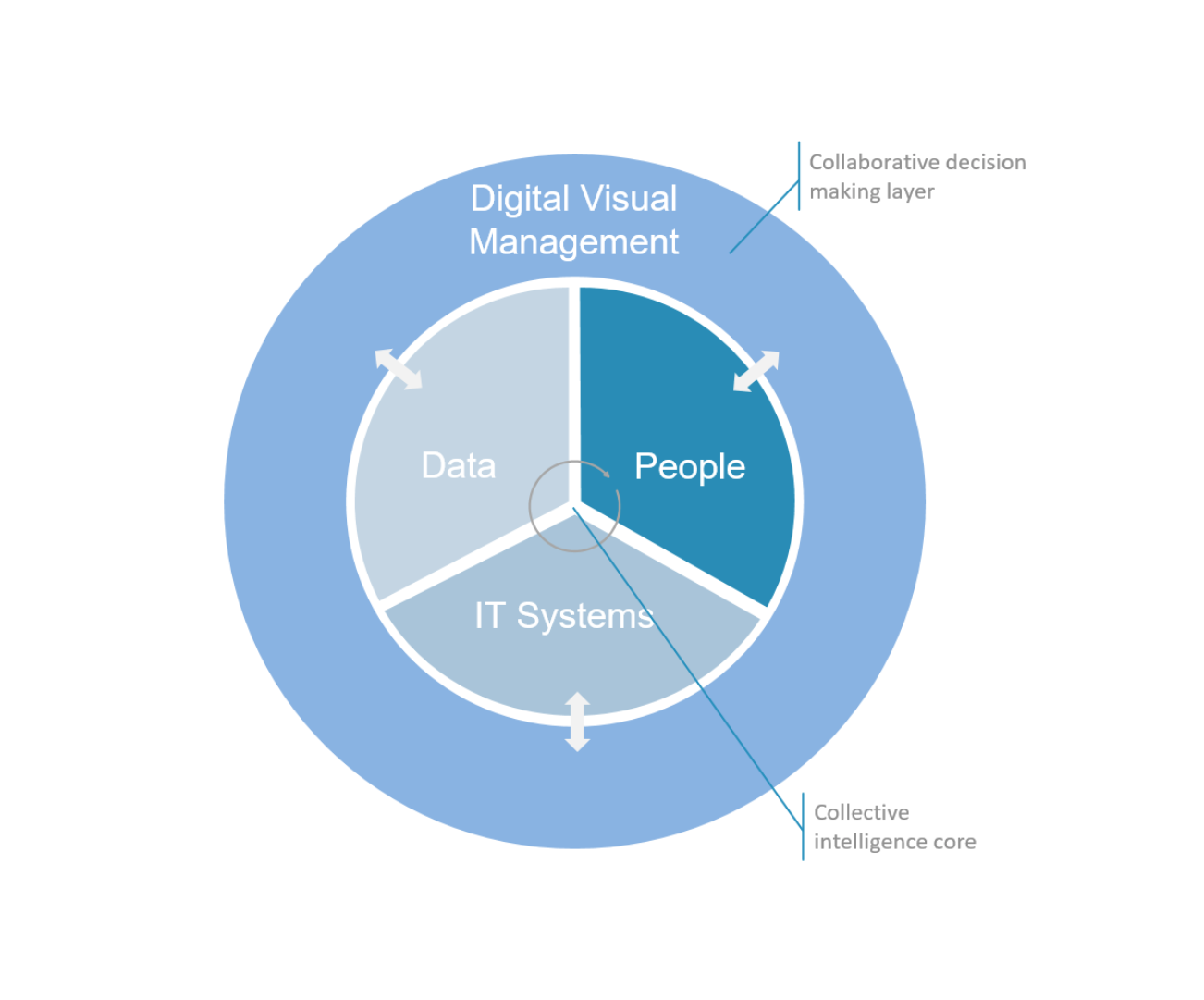

A. Digital Visual Management is a virtual meeting point in space and time; like the central square of a town, where people come and go and gather at specific moments. These gatherings – often global – encourage participants to learn, negotiate, make decisions.

Collaboration

Collaboration requires pulling relevant information from underlying software layers that are purely operational and based on individual interfaces. Digital Visual Management is the decision-making layer on top of companies’ collective intelligence, made of people, IT systems, and data.

iObeya is a unique DVM solution; inherently, human-centricity makes it a key building block to start any Industry 4.0 journey.

With a mature, inclusive technology, iObeya bolsters cross-generational and cross-functional collaboration, promotes digital literacy among the all groups. It empowers teams, reinforces (Lean) corporate culture, paves the way for collaborative ecosystems (with customers, suppliers and partners), and ultimately helps companies built a robust, long-lasting competitive advantage.

Author Profile: Nicola Olivetti, a Lean Six Sigma Black Belt, currently serves as the Lean and Industry 4.0 Program Director at iObeya. Olivetti was previously the Transformation Leader at Nexans, the cable manufacturer and worked for Roland Berger, a strategy consultancy firm. He speaks five languages. Contact Nicola Olivetti at nolivetti@iobeya.com.