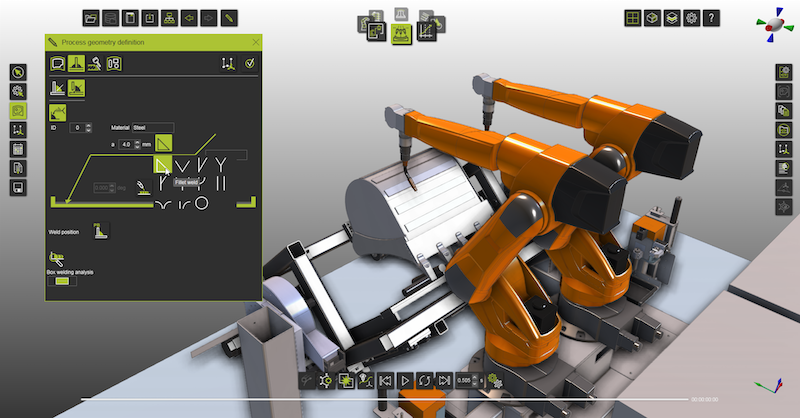

CENIT paves the way to autonomous offline programming

December 17, 2023

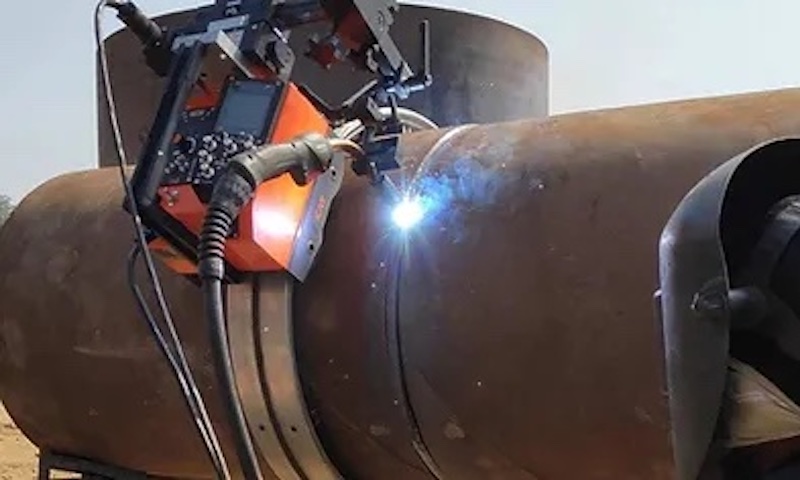

Why You Should Consider Automated Pipe Welding Machines

October 11, 2023

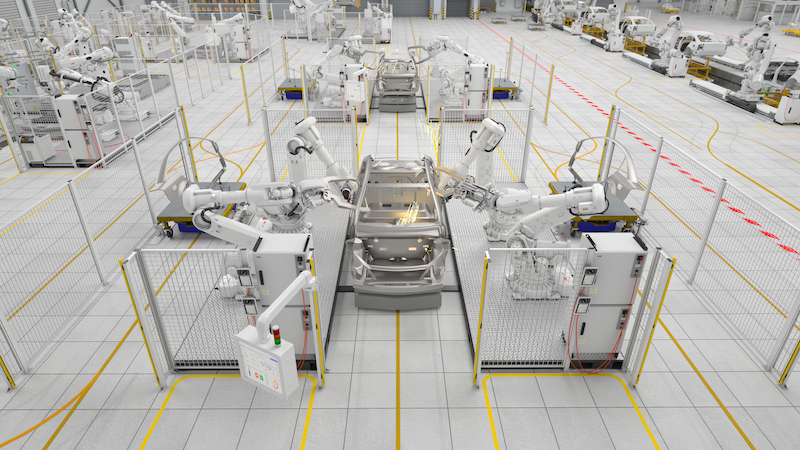

Orbital Welding: Why is it a Great Fit for Fusion Welds?

October 11, 2023

Orbital Welding and its Advantages

September 28, 2023