The use of automation in injection molding has developed beyond the basic part extraction into all-inclusive robotic cells that manage the molding process, inspection, assembly, and packaging.

With seemingly great emphasis on the selection of robots, end-of-arm tooling (EOAT), and control systems, the critical elements that determine the success of automation are often made at a much earlier stage when the product is being designed.

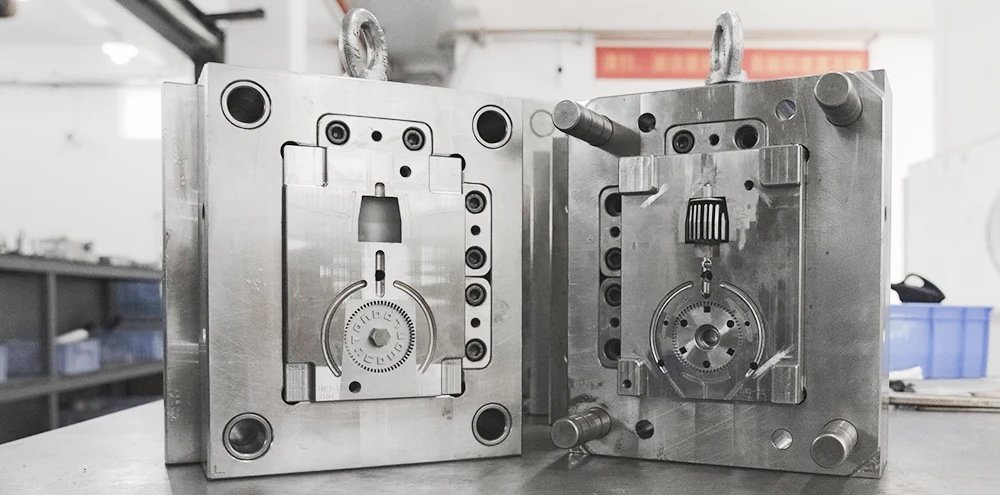

Geometry, material behavior, and handling features of parts have a direct impact on cycle time, and defect rates. Design for Automation (DfA) is a base engineering discipline that connects product design, mold design, and manufacturing productivity. [Read more…] about Designing for Automation in Injection Molding: How Product Design Drives Robotic Manufacturing Efficiency