Natural diamonds are ‘actually lower quality than the kind of diamond we grow for research’, say researchers

Diamond is more than just a gemstone; it is the hardest natural substance on Earth with exceptional qualities for improving semiconductors – the materials used in electronics, electric vehicles and renewable energy technologies.

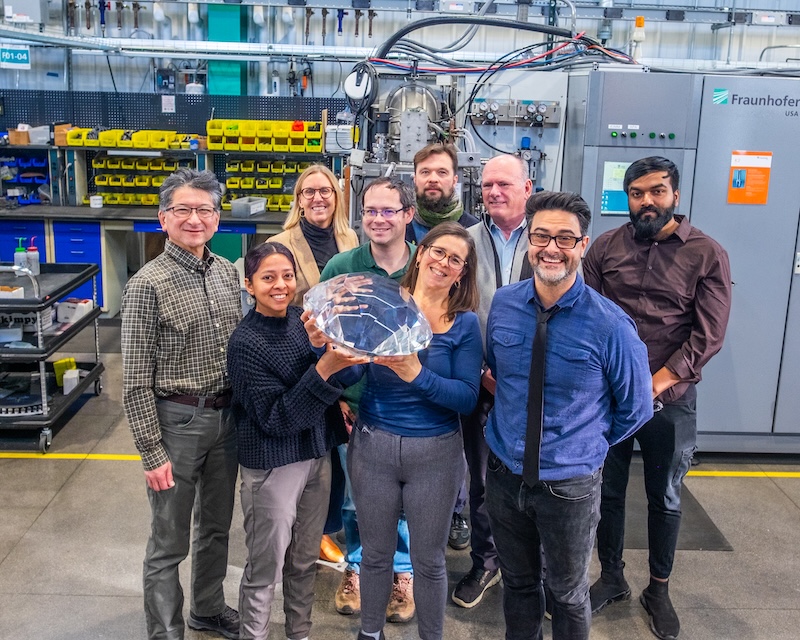

Michigan State University has received a $3 million National Science Foundation grant as part of the NSF’s Future Manufacturing program in collaboration with teams at the Fraunhofer USA Center Midwest and Fraunhofer USA Center Mid-Atlantic.

The teams are using artificial intelligence to grow high-quality diamond in labs, which could be the key to the future of semiconductor manufacturing and advancing workforce talent in the US.

John Papapolymerou, interim dean of the College of Engineering, says: “This is a tremendous opportunity to explore how AI can improve semiconductor manufacturing processes and to develop pathways for our workforce to shift to Industry 4.0 careers converging digital and physical technologies.

“With the help of the NSF, our world-class researchers at MSU and collaborators at Fraunhofer are positioned to make significant contributions to the future of semiconductor production in the US.”

But growing high-quality laboratory diamonds is a lot harder than it seems.

Rebecca Anthony, an associate professor in the College of Engineering, says: “Diamond is a really special material that is formed under only very specific conditions. A gemstone diamond is actually a lower quality than the kind of diamond we grow for research.”

Many semiconductor materials are grown in the lab using a thin layer of one material that acts as a base to grow a different material, layer by layer, on top of it. But diamond grows best on itself.

Using a process called microwave plasma, which is a specialty area for Fraunhofer USA Center Midwest in partnership with MSU, new diamond layers are created. With each layer grown, the material gets wider and, as that happens, imperfections can appear that affect the material’s properties.

Anthony says: “What makes it even more frustrating is that this challenging growth process takes a long time, which means that once we are aware that a defect is present, it’s too late to go back and remake the diamond.

“That’s the big challenge: to grow a high-quality diamond material with as few defects as possible by understanding how they form in the first place.”

To do this, Anthony and her team are using images from a digital single-lens reflex camera, a hyperspectral imaging systems camera, and a forward-looking infrared camera.

The images from these cameras are analyzed using AI by the team at Fraunhofer USA Center Mid-Atlantic in Maryland to help the MSU team examine the growth of the diamond material layer by layer to identify if and where any defects appear.

Anthony says: “Using this information, we can try to predict where and when the defects are forming so that we can tune the process during the growth and prevent these imperfections from forming.

“In the future, we would like this to become more automated as AI can set and adjust the parameters for growing the diamond material we want.”

This grant also focuses on helping to train the semiconductor experts of tomorrow and increase the number of people in the talent pipeline.

The grant will support summer camp opportunities for K-12 students, training for students at Washtenaw Community College in Ann Arbor, outreach to adults already in the workforce who are exploring new career opportunities and educating undergraduate and graduate students at MSU.

This project is also partnered with Automation Alley, a nonprofit technology business association accelerating the growth and global competitiveness of businesses through Industry 4.0 technologies and innovation, that is, technologies that represent the digital transformation of manufacturing and production through smart or AI-based capabilities.

This research began as a seed funding project through the MSU Research Foundation’s Strategic Partnership Grants program. Anthony and her team worked together to coordinate their research efforts to obtain preliminary data that was crucial for securing NSF funding. And, as can be seen from the main picture, the diamond they have grown in the lab is massive and could be worth trillions.

Projects such as this one collectively help shape and advance the MSU Research Foundation’s Hub for Materials Advancement and Research Solutions.

Anthony says: “We need to improve semiconductor materials and the future workforce now. The sooner we get these technology and opportunities in place, the better.”