The use of automation in injection molding has developed beyond the basic part extraction into all-inclusive robotic cells that manage the molding process, inspection, assembly, and packaging.

With seemingly great emphasis on the selection of robots, end-of-arm tooling (EOAT), and control systems, the critical elements that determine the success of automation are often made at a much earlier stage when the product is being designed.

Geometry, material behavior, and handling features of parts have a direct impact on cycle time, and defect rates. Design for Automation (DfA) is a base engineering discipline that connects product design, mold design, and manufacturing productivity.

Product Design as the Foundation of Automation Efficiency

Robots work in harshly limited cycle window environments in automated molding environments, with repeatability being essential. The slightest inconsistencies in releasing parts, in dimensional stability, or cooling can be propagated into robotic mispicks, errors in places, or failure in the subsequent processes.

The design decisions of products define the physical and dimensional attributes that the robotic system will be dealing with. Automation-conscious designs incorporate predictability, rigidity, and handling logic in the part, minimizing the mechanical load on robots and stabilizing production performance.

Geometry, Material Behavior, and Robotic Interaction

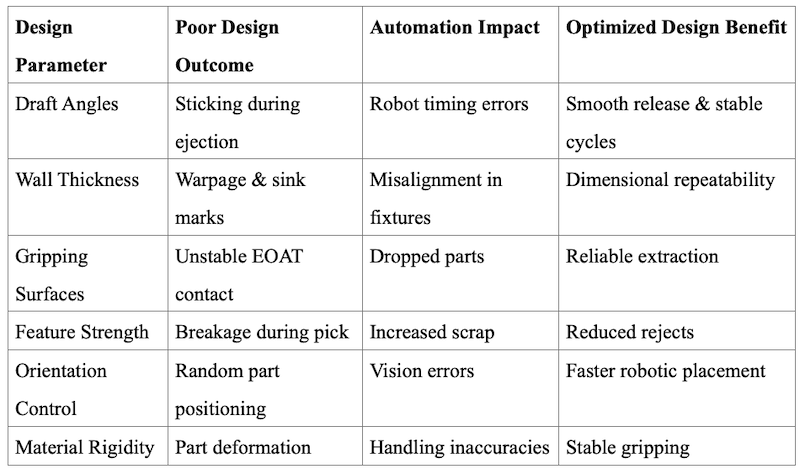

The geometry of the parts dictates the success of robots in gripping, pulling, and placing molded items. Vacuum cups and mechanical grippers are both challenged by surfaces where flats are not available or contact can not be predicted.

Rigidity in structure also becomes significant especially since the extraction of parts is often carried out at high temperatures when the polymer becomes less rigid. Another geometric fact is orientation stability, where being able to tumble or differing landing poses a difficulty in the robotic alignment, as well as vision-guided systems.

Robotic interaction is also further modified by material selection. Most polymers with high thermal flexibility can lose shape during extraction, and materials with large static content can destroy the vacuum gripping performance.

Brittle resins cause more danger of crack-out on the mechanical grips, and over-soft materials spoil dimensional accuracy. Good automation requires injection mold materials with impact resistance, thermal stability, and surface properties that are compatible with gripping and optical systems.

Dimensional Stability, Cooling, and Ejection Dynamics

Even wall thickness is another established principle of molding, but in automated conditions, the uniformity of the thickness becomes even more critical. Non-uniform parts give rise to differential cooling, which results in warping, a change in shrinkage, and uneven ejection forces. These dimensional variations disturb the robotic placement and alignment of fixtures.

Draft angles are also important; when the draft is too small, there is more friction in the demolding process, which causes a longer ejection time, and it is also not evenly spaced, disrupting robot timing. Undercuts and laterals also create mechanical complexity and a possible risk of a lack of synchronization between the movement of the mould and the robots entering it.

Dimensional repeatability and recognizable reference geometry are also needed in vision systems built into automated cells. Optical recognition and inspection rely on surface reflectivity, texture, and edge definition to affect the accuracy and reliability of the optical recognition and inspection.

A robot enters the open mold to extract the molded part immediately after ejection.

Mold Design and Automation System Integration

The successful automation of injection molding requires close coordination between the robot system behavior and the architecture of the molds. Mold designing choices have a direct effect on the accessibility of robots, the reliability of extraction, and synchronization of cycles.

Gate locations should not be in robotic gripping areas, cosmetic Class A, or functional datums. The improper positioning of the gates may undermine the vacuum closure, create a state of handling instability, or necessitate secondary trimming procedures that may disrupt automation.

Efficiency of cooling determines the part’s hardness when it is ripped by the robot. Poor or imbalanced cooling causes thermal deformations, variation in dimensions, and variation in gripping.

Preliminary communication among injection molding service providers, product designers, mold engineers, and automation experts is necessary to make sure that the mold mechanics, thermal behaviour, and robotic motion plans are not autonomous components but instead a single production system.

Design for Downstream Automated Operations

The efficiency of robots does not stop at removing parts during assembly, welding, inspection, labeling, and packaging. The choice of product design determines the smoothness of such downstream operations or the complexity of the compensatory automation.

Snap fits, alignment bosses, and press-fit interfaces should have features that allow the variation of dimensions yet maintain high strength in the presence of automated insertion forces. The effects of poor tolerance stack-ups include assembly jamming or high force loads that consume equipment reliability.

Operational and Economic Implications

The design choices directly determine the efficiency of robots and the effectiveness of equipment at large. The sub-optimized components add downtimes and scrap rates, as well as maintenance interventions, diminishing the value of automation investments.

In contrast, parts developed using robotic handling and stability of cooling and demolding properties can be used to reduce cycle time, ease of EOAT, and process robustness.

Automated assembly, trimming, and packaging are downstream processes that are similarly impacted. Snap-fit reliability, and stackability can determine how the robotic systems run with desired throughput or employ some compensatory complexity. Finally, the success of automation in injection molding is predetermined to a great extent in the design stage of the product.

Blocks that are produced with the knowledge of the behavior of molds, material reaction, and robot interaction provide high manufacturing efficiency, reduced operational variability, and better economic performance.