As the construction sector grapples with stubborn labor shortages, rising costs, and mounting pressure to deliver housing at scale, a new class of automation companies is emerging that promises to reshape how homes are built.

One of the most intriguing among them is Reframe Systems, a technology company that blends industrial robotics, artificial intelligence, and advanced manufacturing to automate large chunks of the construction process that have long resisted mechanization.

Founded on the conviction that real-world productivity gains require more than isolated bricklaying robots or simple material movers, Reframe describes its approach as “physical AI” for construction – applying robotics and automation within controlled factory environments to deliver repeatable, high-quality building components at scale.

Rather than chasing headlines with site-borne robots, the company focuses on the factory floor where panel fabrication, framing, cutting, fastening, and material handling can be done with precision and consistency under machine control.

At the helm is Vikas Enti, CEO and co-founder of Reframe Systems. Enti is a veteran of Amazon Robotics who helped oversee the deployment of more than half a million robots in high-volume logistics environments.

Enti’s experience in scaling automation for one of the world’s most demanding production networks now informs Reframe’s mission: to unlock significant portions of housing production through integrated robotics, while still keeping skilled builders at the heart of the craft-driven finishing work that defines quality homes.

In this email Q&A, Enti walks us through how Reframe’s automation systems work today, where the industry still lags, and what the broader market could look like if construction embraced automation not just as a set of tools, but as a fundamental production model – one capable of boosting capacity, improving safety, and lowering cost and carbon footprints in one of the world’s most challenging sectors.

Interview with Vikas Enti, CEO and co-founder, Reframe Systems

Robotics & Automation News: Reframe describes its process as “physical AI” for construction. At the practical level, what robotics systems are you deploying today on the factory floor, and which stages of homebuilding are currently automated end to end?

Vikas Enti: We’re developing a robotics and vision platform to unlock automation of approximately 60 percent to 80 percent of work content.

Today, our primary focus for automation is in panel production.

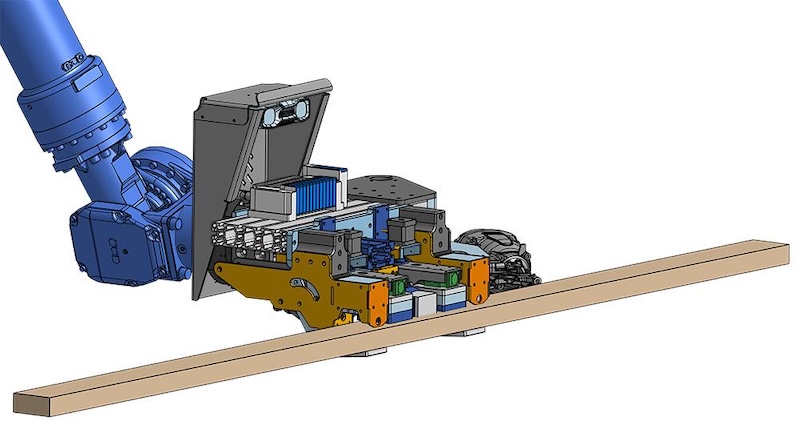

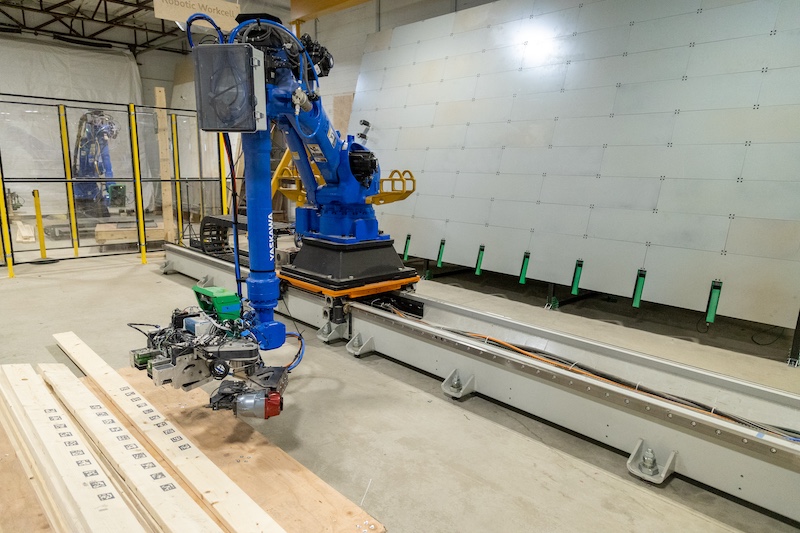

Inside the production network, robots take on the repetitive and physically demanding tasks involved in framing and assembling wall and ceiling panels – measuring, cutting, fastening, handling materials and more that would traditionally be lifted and aligned manually.

Beyond that, humans lead module assembly, MEP, finishes, and all on-site installation as these require adaptability and field expertise. Our goal is to continue expanding automation within the factory over time, while keeping skilled labor central to the overall process.

R&AN: Construction automation has traditionally focused on isolated tasks like bricklaying, welding, or material transport. What parts of your process are automated that are not typically automated elsewhere in the construction sector?

VE: Most construction robotics focuses on single tasks – like bricklaying, welding, or moving materials. Our model automates the repetitive steps required to manufacture panels that meet local codes and energy standards. Instead of automating one action, we automate a key section of the production sequence inside a production network.

Because our production networks operate indoors and in controlled conditions, we can automate work that would normally happen on an open jobsite – such as framing, fastening, and handling heavy materials – and do it with consistency regardless of weather or site conditions.

R&AN: You come from Amazon Robotics, where you oversaw implementation of more than 500,000 robots. How much of that experience translates directly to construction, and where did you find the biggest differences in applying high-scale automation to a sector that has historically resisted it?

VE: A lot of the fundamentals translate directly: systems engineering, workflow automation, safety, and integrating robots that interface with people to mass-customize orders.

The biggest difference is obviously the amount of work content in building a home vs assembling an ecommerce order.

At Reframe, we took the parts of Amazon’s playbook that work (standardized inputs and work, automation of repetitive tasks, augmenting humans with advanced interfaces) and adapted them to our own distributed production network built for the real-world constraints of housing.

R&AN: What percentage of Reframe’s production workflow is currently automated, and what percentage do you believe is realistically automatable within the next 3-5 years?

VE: We’re currently automating about 20 percent of the tasks with framing of walls and ceilings.

Over time, we’re aiming to automate 60-80 percent of factory tasks, including finishing tasks (painting, drywall), insulation, component installation (windows, cabinets) and inspections

R&AN: You’ve emphasised that your robots take over repetitive and physically demanding tasks rather than replace skilled labour. Can you give examples of tasks that have been “robotised” at Reframe, and how that has changed the role of the builder or craftsperson?

VE: Panel fabrication tasks like cutting, fastening, lifting, and aligning framing components are now handled by robotics inside the production network. These tasks are physically taxing and repetitive, making them good candidates for automation.

Builders now focus on higher-skill work – installing windows and doors, performing MEP, completing finishes, and handling the details that define quality. Automation reduces physical strain while giving workers more time for the craft-driven parts of construction.

R&AN: Reframe says it can build homes 2.5x faster, at 35 percent lower cost, and with 10x fewer emissions. How much of these gains are directly attributable to robotics and automation, versus design, materials, or process engineering?

VE: The gains come from the entire system working together. Automation improves throughput and consistency in the factory, but equally important are:

- Production networks located close to projects, reducing delays and transportation costs

- Off-site manufacturing, which allows parallel site prep and factory work

- Standardized building systems that reduce rework and uncertainty

- All-electric, solar-ready, fire-resilient designs that reduce operational and embodied carbon

Automation is a key enabler, but the speed, cost, and carbon improvements come from combining robotics with a new production model and a climate-resilient building platform.

R&AN: If the wider construction industry adopted the level of automation you’re developing, where do you see the biggest impact: labour shortages, safety, cost reduction, quality control, carbon reduction – or something else entirely?

VE: The most immediate impact would be expanding overall production capacity – addressing the labor shortage by reducing the amount of repetitive, physically demanding work and letting builders focus on higher-skill tasks.

Beyond that, factory-built components improve consistency, safety, and quality while reducing construction waste and carbon footprint. Automating the right segments of the workflow would help produce homes more predictably and at the scale needed to address both housing and climate challenges.

With a 4.7 million home shortage, the US can’t afford incremental gains. If the industry adopted the level of automation we’re building, we could expand capacity where it matters most.

That’s at the core of Reframe’s mission: use automation to multiply human capability so communities can get high-quality, climate-ready housing on a timeline that matches the scale of the crisis.