Dexory, a provider of real-time warehouse data intelligence and robotics, has launched its next-generation autonomous robot and a new software feature, “Storage Health”.

Both of these new capabilities enhance warehouse efficiency and visibility by delivering richer, more accurate operational data.

Since 2023, Dexory robots have been operating in live warehouse environments, helping operators capture accurate, real-time visibility across their facilities.

Building on this proven foundation, Dexory is now introducing the next evolution of its autonomous robot design, which is faster, more efficient, and capable of capturing significantly more data across increasingly complex warehouse operations.

The new robot operates safely alongside people and machinery without disrupting daily workflows. It captures high-frequency warehouse data and continuously feeds a live view of operations into Dexory’s digital twin platform, DexoryView.

With an extended scanning range of up to 60 feet (vs. 40 feet in the current generation), the robot can process more data, faster.

This delivers consistent visibility across racks of all shapes and sizes, including double-deep configurations, block storage, and other non-racked environments, creating a reliable data layer across the entire warehouse at the click of a button.

Richard Williams, VP of robotics, Dexory, says: “Warehouse performance depends on how closely operational systems reflect reality on the floor.

“By continuously capturing accurate data across every storage type and operational area, our next-generation solution gives customers a trusted, real-time foundation for decision-making. This enables warehouse operators to make decisions based on what is actually there, not what they assume is true.”

The robot’s modular architecture also ensures future-proofing, allowing warehouses to seamlessly integrate additional capabilities like pick face analysis or temperature monitoring without costly overhauls.

Customers using existing Dexory’s systems have already seen remarkable results, including 80 percent reduction in audit time and 20 percent throughput improvement. The new capability extends these performance gains, solving visibility issues across all complex configurations.

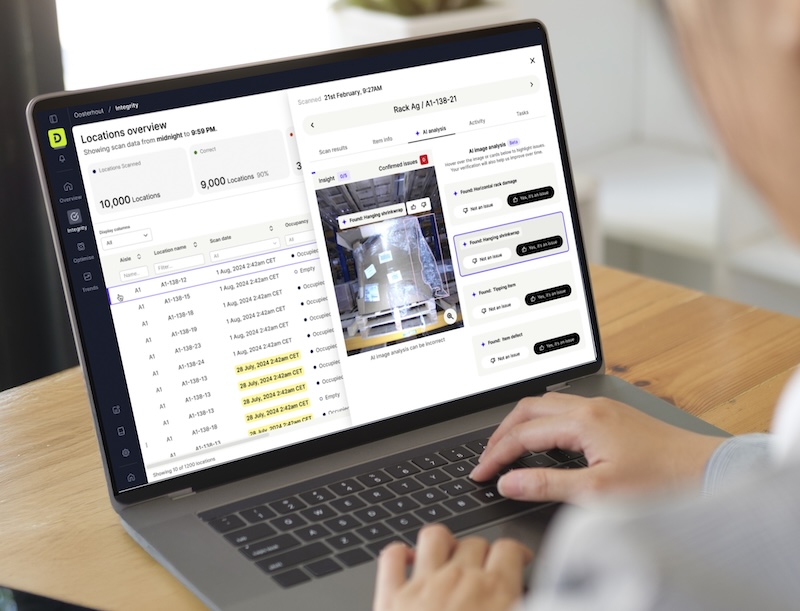

Complementing the new hardware is Storage Health, a software feature powered by computer vision and AI. Running in the background during every scan and analysing the high resolution images captured in real time, Storage Health acts as an additional layer of inspection, identifying critical issues that frequently go unnoticed during manual checks.

The feature identifies and flags potential hygiene and stock risks across all rack levels. This includes damaged racking, defective pallets, and unstable items that could collapse and endanger workers; hanging shrink wrap and empty pallets that create fire, contamination, and obstruction risks; and damaged or crushed goods that undermine stock control, driving loss and rework.

Chris Coote, director of product at Dexory, says: “The biggest risks often sit higher up or deeper in the racks where manual checks are infrequent and ineffective.

“Storage Health changes this, enabling operations, health and safety, and inventory teams to act early and reduce risks before they escalate into costly incidents, injuries, or compliance issues.”

Dexory says this dual launch reinforces its commitment to providing complete, continuous intelligence, allowing warehouse operators to gain full visibility, think smarter, and move faster than ever before. The first public showcase of these solutions will be at Manifest 2026, booth #1055, from February 9-11, 2026.