By Ulrich Schäfer, project engineer, ZASCHE handling

Industrial manipulators are essential tools for lifting, moving, and positioning heavy or complex components.

They improve safety, reduce operator strain, and support higher productivity across companies of all sizes – from small manufacturers to major players in sectors such as automotive, printing, and heavy industry. But with several different designs available, how do you know which manipulator is the right fit for your task?

Here we review the key considerations for specifying a manipulator, with a side-by-side comparison of articulated and parallelogram systems – the two designs most commonly found in industry today.

Manipulators explained: More than just a lifting aid

Manipulators are ergonomic handling devices designed to support human operators in tasks that would otherwise require excessive force or awkward positioning.

Unlike robots, manipulators are built to work alongside people, providing strength and reach while leaving judgment and control in the operator’s hands.

In this way, they strike a balance between machine assistance and human control: the operator stays in charge of judgment-based movements while the device provides the strength, reach, and stability needed for safe handling.

This makes manipulators especially valuable in applications where parts are heavy, repetitive tasks must be performed, or where loads must be kept stable and level.

Key factors That shape the right manipulator choice

Selecting the right manipulator is rarely a one-dimensional decision. In practice, there are five factors that should guide operation managers in making the right choice.

For most decision-makers, payload is the natural starting point, since every manipulator has limits defined not only by the weight it can carry but also by how that weight is distributed. Depending on the application, however, other considerations may take precedence.

Reach is often a defining factor in a space-constrained facility, as the distance a manipulator must cover often dictates capacity and layout.

A short-reach arm may offer higher payload but be unsuitable for spanning across multiple workstations or large pallets. That said, it is possible to integrate manipulators with crane systems to extend the reach.

Load orientation becomes critical when the part must remain level or aligned. Containers of liquids, for instance, cannot be tilted without risk of spillage, while fragile electronics must stay upright to avoid damage.

In other cases, the ability to rotate a panel or shaft into position may be just as important as lifting it in the first place.

Ergonomics and safety ensure the operator can work efficiently without strain. Smooth, intuitive movement reduces fatigue over a shift and limits the risk of musculoskeletal injuries – benefits that often translate into higher productivity.

And finally, the environment often sets strict boundaries. High heat, dust, or explosive atmospheres require robust, specialized designs, while sensitive settings like clean rooms call for protective covers to maintain a controlled, contamination-free workspace.

Together, these five factors form the framework for evaluating any manipulator, helping narrow the choice to the designs that best match the task.

Articulated vs. parallelogram: Where each design excels

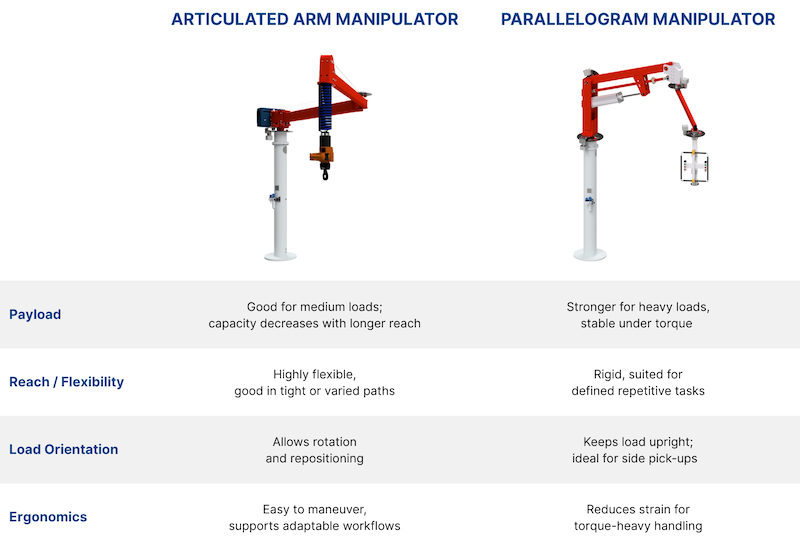

When the decision narrows to articulated versus parallelogram manipulators, the distinction comes down to how each design responds to the same set of factors.

Articulated arms are flexible, multi-jointed devices that perform well in classic pick-and-place applications, particularly when the load can be gripped at its center of gravity. They thrive in tighter spaces and are well suited to medium loads, although capacity decreases as reach increases.

Parallelogram manipulators, by contrast, are built for stiffness and stability. They excel at handling heavier parts, side pick-ups, or tasks that generate torque.

Because they keep loads upright and steady, they are often preferred for applications that demand precise alignment – such as joining components or positioning large assemblies.

The comparison table below summarizes how these two types measure up across the most important criteria.

Turning factors into a decision

What these distinctions show is that the right manipulator is always defined by the application. If the priority is agility and efficient movement for center pick-ups, articulated arms are often the best fit. If torque resistance, heavy loads, or strict load orientation are involved, the parallelogram provides greater control and safety.

Space and mounting options also influence the decision. A ground- or column-mounted manipulator is usually the most economical solution, while crane- or suspension-mounted systems allow one operator to cover multiple stations or larger work envelopes.

These practical considerations, combined with the basic factors of payload, reach, and ergonomics, determine which design offers the best balance.

Every choice comes with trade-offs. Extending reach reduces payload capacity, flexibility carries higher cost than fixed systems, and efficiency must always be weighed against operator safety. The goal is not to find a universal solution, but to specify a manipulator tailored to the demands of your process.

From criteria to confidence

Choosing a manipulator may seem complex, but once the core factors are clear – payload, reach, load orientation, ergonomics, and environment – the decision becomes far more straightforward.

The comparison between articulated and parallelogram manipulators highlights that each design excels in different areas, and the right choice is always context dependent.

Ultimately, manipulators are not just about lifting – they are about enabling people to work more safely, more precisely, and more sustainably.

The best outcomes come when equipment design is matched with long-term expertise and support, ensuring these systems continue to serve evolving needs on the factory floor.