Fabric8Labs, a company pioneering electrochemical additive manufacturing, has announced a $50 million funding round to expand its US-based advanced manufacturing facilities, boosting capacity to produce tens of millions of components annually.

Powered by its breakthrough Electrochemical Additive Manufacturing (ECAM) technology, Fabric8Labs is scaling up production of next-generation electronics components that enable leading-edge systems in thermal management (AI/HPC), wireless communications (RF), and power electronics.

The US-based manufacturing footprint enables customers to move seamlessly from prototyping to high-volume production.

New investment fuels growth

Fabric8Labs has secured $50 million in its latest round of financing, led by NEA and Intel Capital, with participation from existing investors Lam Capital, the corporate venture arm of Lam Research, TDK Ventures, and SE Ventures, as well as new investors Marunouchi Innovation Partners, SK hynix, Ericsson Ventures, Masco Ventures, and Toppan Global Venture Partners.

The new funding will accelerate:

- Capacity expansion: Ramp production of Fabric8Labs’ US manufacturing footprint from 5 million to 22 million components per year to meet growing demand across thermal management, RF, and power applications.

- Team growth: Expand the team across manufacturing, design, quality, and process engineering to support growth customer programs.

- Production ramp-up: Expand production team to support engagements inAI/HPC thermal management, RF/wireless, and power electronics, moving quickly from first article to full production.

Jeff Herman, co-founder and CEO of Fabric8Labs, says: “This investment accelerates our mission to scale Electrochemical Additive Manufacturing (ECAM) for customers in high-growth, fast-moving industries where we are solving their most demanding challenges.

“With ECAM, we’re reshaping how critical components are designed and manufactured—delivering the performance, reliability, and supply chain resiliency that enables customers to rapidly innovate and deploy advanced systems.”

Fabric8Labs’ advantage

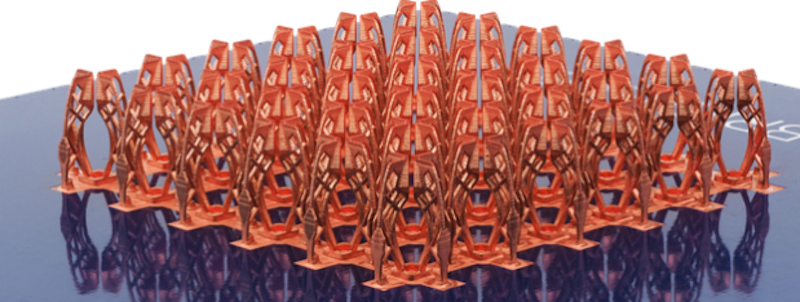

Fabric8Labs has pioneered the most advanced additive manufacturing platform – Electrochemical Additive Manufacturing (ECAM).

ECAM is a room-temperature metal additive manufacturing technology that leverages electroplating principles to create ultra-high resolution, three-dimensional metal parts without the need for expensive post-processing.

Components are rapidly built at the atomic level, resulting in excellent feature resolution and surface finish – ideal for applications in multiple industries:

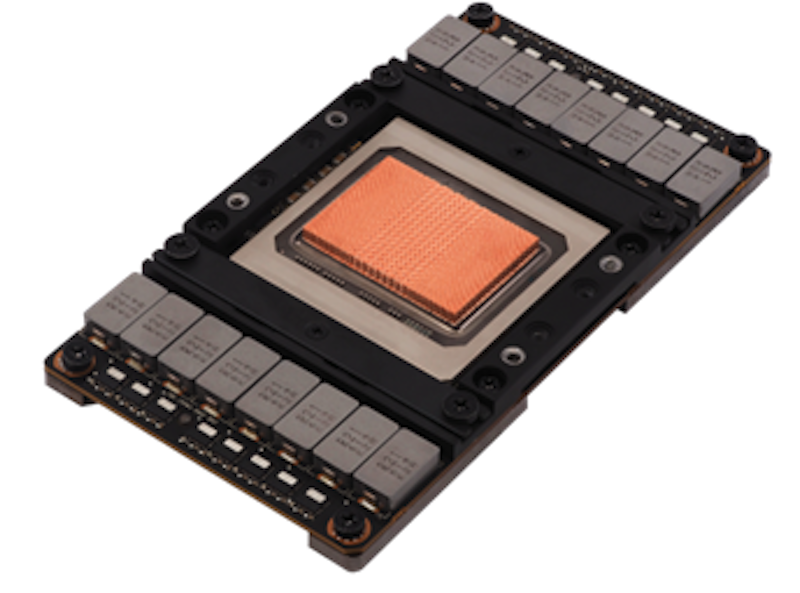

Thermal management

With the rapid growth of AI data centers, advanced thermal management solutions are becoming critical to ensure performance, efficiency, and reliability.

From single-phase direct-to-chip (DTC) cooling to cutting-edge direct-to-silicon immersion systems, ECAM technology ensures next-generation AI and HPC chips will stay cooler under ever-increasing power densities.

Wireless communications (RF)

Communications systems requirements increasingly demand faster, more efficient wireless systems that can be integrated into compact, space-constrained devices and infrastructure.

Fabric8Labs leverages its room-temperature process to fabricate 3D antennas directly onto PCBs and high-performance substrates – optimizing size, weight, power, and cost (SWaP-C) for systems in low Earth orbit (LEO) satellite constellations, wireless backhaul networks, and mobile vehicle communications.

Power electronics

Vehicle electrification requires components that deliver higher efficiency in smaller, more reliable packages. ECAM-fabricated high-current interconnects and passive components, which can be printed directly onto high-performance ceramics, reduce assembly steps and material interfaces, resulting in more compact, efficient EV systems.

Supporting the team

Greg Papadopoulos, PhD, Venture Partner at NEA, says: “We believe Fabric8Labs is redefining additive manufacturing with its breakthrough ECAM technology.

“Early on, we recognized the potential of ECAM to deliver unmatched precision, scalability, and design freedom – unlocking new opportunities across thermal management, aerospace, and power electronics. We’re thrilled to continue supporting the team as they expand US production and scale this transformative platform.”

Customers increasingly require a US-based components manufacturer to supply these advanced products and advance concepts from prototype through production.

Fabric8Labs’ US-based manufacturing footprint is ISO9001 certified and ITAR registered; ensuring high quality and reduced supply chain risk for customers. Fabric8Labs is sharing a look inside its first ECAM facility to showcase the future of manufacturing.

See ECAM in action

With this new investment, Fabric8Labs is poised to redefine how critical technologies are designed, manufactured, and integrated at the system level.

By combining US-based production capacity with its ECAM process, the company is enabling a new era of advanced manufacturing – one that empowers innovation and strengthens supply chains, enabling the next generation of AI infrastructure, electronics, aerospace, and energy systems.