Earth-moving equipment has always been a symbol of raw mechanical strength – thundering engines, hydraulic muscle, and the unmistakable hum of steel meeting soil. But over the last decade, the construction and hire sectors have been quietly rewiring their future.

Sensors, automation platforms, AI-driven precision, and robotics are now shaping a new generation of diggers that no longer rely solely on human hands. What once required long hours, expert operators, and considerable on-site coordination is becoming more efficient, safer, and far more predictable.

Contractors looking for an edge are increasingly turning to smarter machines, and hire companies are recognising that a fleet can no longer compete on horsepower alone. The shift from conventional diggers to semi-autonomous and fully robotic earth-movers is reshaping the entire rental model.

Robotics and Porter Group: The Starting Point for a Smarter Hire Market

Whether a contractor needs a mini excavator for tight urban work or a heavy unit for bulk earth-moving, the hire journey often begins with companies like Porter Group – one of the most recognised names in rental machinery. Their Porter excavator hire services cover a broad range of machines, all showcased on their site.

Traditionally, Porter Hire has supplied conventional mechanical diggers, but their current fleet shows the early signs of intelligent evolution. Many models already include GPS-ready systems, advanced operator assistance, and digital monitoring capabilities.

These features are foundational for the next step: automated digging, semi-autonomous trenching, and ultimately robot-ready performance.

The industry’s direction is clear. As automation becomes embedded into the design of excavators – whether through manufacturer-installed intelligence or third-party retrofit systems – hire providers like Porter Group will increasingly offer machines that deliver smarter, more consistent results.

Even if Porter Hire’s fleet today is centred on operator-driven models, the structure is in place for rapid transition.

World-leading automation companies have already proven that excavators can be upgraded with autonomous capability. Built Robotics, for instance, retrofits standard hydraulic diggers with robot control systems.

This means that a future Porter Hire excavator could arrive on a site not only ready to dig but ready to decide the best way to dig, reducing labour pressure and improving on-site safety.

For contractors, the implications are substantial. Instead of hiring a machine and an operator, the future hire model might be “machine + autonomy + remote supervision”.

Productivity becomes measurable, predictable, and less dependent on human operator variability. The first step of the revolution starts exactly where it always has: with the hire yard, now transformed by robotics.

Komatsu: The Manufacturer Leading Intelligent Machine Control

If hire companies reflect the demand side of this shift, Komatsu reflects the supply side. Their “Intelligent Machine Control (iMC)” platform is one of the most advanced semi-autonomous excavator technologies available today. Unlike retrofit systems, Komatsu builds intelligence directly into the machine at the factory.

iMC combines:

- GNSS guidance

- Real-time position sensing

- Stroke-sensing hydraulic cylinders

- Automated digging assistance

- Precision grading control

These systems allow an excavator to dig to a target depth or grade with minimal operator intervention. The machine prevents over-cutting, reduces rework, and performs many repetitive tasks independently. For hire fleets, this is a game-changer.

A single iMC-enabled excavator can deliver the accuracy of a top-tier operator while reducing fatigue, inconsistencies, and human error.

Hire companies around the world are steadily adding these machines to their fleets because they give contractors a significant performance advantage.

Komatsu’s autonomous features mean even less-experienced operators can achieve professional-level output, reducing the need for deep labour pools and widening the skill accessibility of construction sites.

The excavator becomes not just a tool, but a guided system – halfway between traditional equipment and a full robotic unit.

Built Robotics: Turning Ordinary Excavators into Autonomous Earth-Movers

While Komatsu focuses on building intelligent machines at the factory, Built Robotics offers the opposite strategy: transforming existing machines into fully autonomous platforms.

Their Exosystem retrofit kit attaches to common excavator models and delivers autonomous trenching, obstacle detection, remote monitoring, and real-time activity reporting.

The appeal for hire companies is immediate:

- Upgrade existing inventory instead of buying new units

- Offer autonomous operation as an add-on service

- Reduce the number of on-site operators needed

- Increase productivity through multi-shift robotic work cycles

Built Robotics positions autonomy as a service layer. A hire company could provide a standard excavator at one rate, and an “autonomous-ready” excavator at a premium, giving contractors flexibility based on budget, project size, and complexity.

This aligns perfectly with the emerging trend of “performance-based rental”, in which clients pay for the value delivered rather than the hours the machine sits on site.

With safety-certified robotics systems and digital monitoring, contractor risk is lower, and tasks such as trenching for utilities become faster and more uniform.

Built Robotics brings the hire industry closer to a world where autonomy is simply an optional checkbox, much like choosing a GPS system or hydraulic thumb attachment today.

ASI: Orchestrating Entire Fleets With Autonomous Control

Autonomous Solutions Inc. (ASI) pushes the concept even further by enabling entire fleets of machines to operate collaboratively. Their Mobius platform unifies excavators, haul trucks, loaders, and dozers into a single command system where machines can work with minimal human oversight.

For hire companies, Mobius represents the future of fleet-based rental service:

- Mixed fleets of human-driven and autonomous machines

- Centralised monitoring and dispatching

- Automated cycle optimisation

- Safer work zones through geofencing and obstacle detection

A contractor may soon hire not a single robot excavator, but a coordinated robotic earth-moving team. Hire providers could offer “site automation packages” where machines perform excavation, loading, and grading tasks under software-driven scheduling.

This shifts rental from equipment supply to full operational support – the true hallmark of the next hire revolution.

Wrapping Up

The global hire industry is preparing for a breakthrough that will redefine how contractors work, budget, and plan their projects.

Porter Group stands at the familiar starting line – the rental yard where most construction projects begin – but robotics and autonomy are pushing the boundaries of what these fleets can deliver.

Komatsu’s factory-integrated automation, Built Robotics’ retrofit autonomy systems, and ASI’s fleet command platforms illustrate a complete ecosystem in motion.

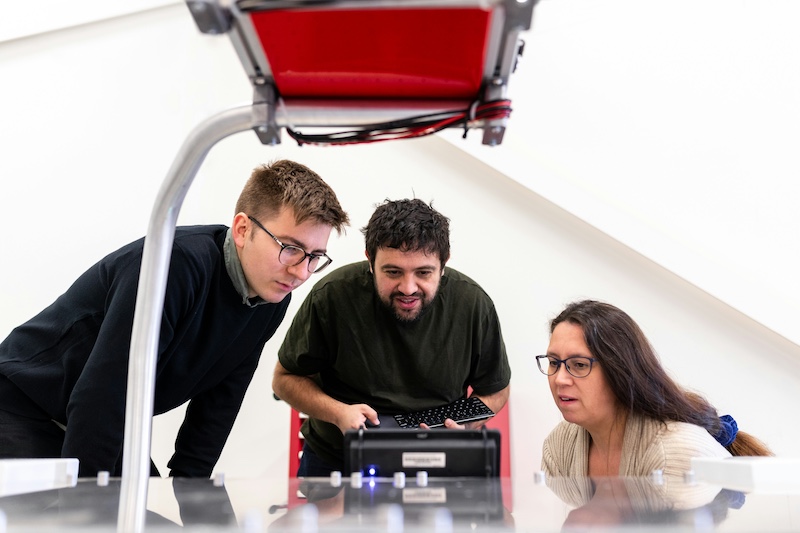

Main image by Izzuddin Azzam on Unsplash