Tight protocols keep controlled rooms free of dust and residue. Every surface, instrument, and step inside these spaces supports quality and stability.

As more industries bring in smart machines, upkeep methods are shifting toward approaches that cut slip-ups while backing the reliability of familiar cleaning gear.

New tech now works alongside careful use of swabs and other supplies. Rather than replacing them, programmable systems help these items work with better steadiness.

This mix helps shape the next phase. One where accuracy and routine emphasize the value of even the smallest implements.

The Growing Role of Mechanization

Across sectors that rely on sterile rooms, facilities are adopting machine-driven support. Units with calibrated sensors move through regulated areas without adding new particles, which trims risks tied to frequent people traffic. The shift centers on balance, not just speed, in places where tiny specks can derail a whole run.

Bringing in smart equipment also reflects a wider mindset change inside production and research teams. Organizations see technology as a partner to established practice, keeping operations both efficient and dependable.

While systems gain more capability, the purpose remains the same. Protect outputs, end users, and workflows from impurities that do not belong.

Why Precision Tools Still Matter

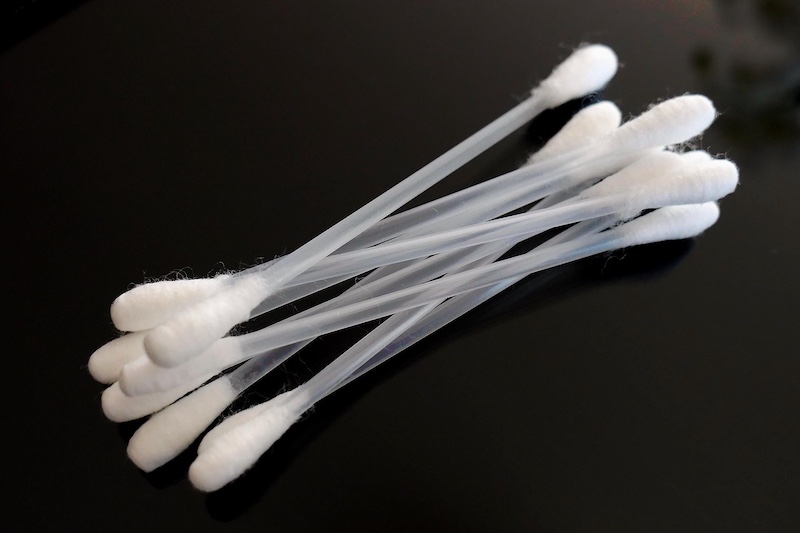

High quality clean room swabs reach tight channels and delicate parts that large equipment may miss. Their fine touch makes them essential in lines such as chip fabrication and medical device assembly where a single fleck can spoil a complete lot.

Smart gear can ready the space, yet single-use applicators provide the final safeguard. Their purpose proves that advanced platforms do not erase the need for simple, proven instruments. Progress in such work is layered. High-end systems and dependable hand tools must operate together for the strongest outcome.

Reducing Human Error

People bring variables that are hard to control, from uneven wiping to stray contact with sensitive pieces. Machine support handles repeated tasks with the same motion each cycle. This steadiness lowers mistakes and keeps results from depending on personal technique or fatigue.

By shrinking opportunities for slip-ups, automated routines raise trust in cleanliness programs. Teams remain vital for judgments and close reviews, and their work is reinforced by platforms that limit oversights. Such balance further lets controlled rooms keep strict thresholds without placing the entire load on staff.

Enhancing Consistency

Keeping purity high is not only about doing a task once but about doing it to the same level every time. Equipment excels at steady execution in surface care, air checks, and routine verifications. Paired with swabs, these passes keep the most sensitive spots under watch.

Uniform results matter most when lines run without pause and stoppages must be avoided. Programmed routines uphold standards all hours, while swabs let crews treat exact areas with care. Together these methods show that cleanliness is both broad coverage and close detail.

The Hybrid Future

The road ahead does not point to a single method. A blended path is taking shape where machine-driven cycles handle recurring work and people use swabs and other implements for focused sanitation. Each approach plays to its strengths and fills gaps for the other.

This mix also gives room to adapt. When new needs appear, teams can tune the split between machine cycles and hand work. That flexibility keeps controlled rooms ready for change while still relying on practices that have earned trust over time.

Endnote

Purity management is moving into a phase where technology and familiar instruments strengthen each other. Smart equipment brings reliable checks, and swabs supply careful, point-by-point care. Together, they protect sensitive work with greater assurance and efficiency.