Berkshire Grey launches ‘reverse logistics’ solution to deal with e-commerce goods returns

Berkshire Grey, a warehouse robotic solutions company, has introduced its “Reverse Logistics solution” to help retailers accelerate the resale of returned goods and improve labor utilization in the returns process.

Projections indicate that by the end of January, consumers will return approximately $120 billion of goods following the holiday season, creating a significant inventory and cost challenge for retail.

By implementing Berkshire Grey’s Reverse Logistics solution for returns processing, e-commerce providers and retailers can reduce the time to recirculate returned items back onto the shelf and optimize labor productivity, ultimately improving profitability.

Steve Johnson, president and COO of Berkshire Grey, says: “Returns processing has a significant adverse impact on the real profitability of e-commerce.

“As online shopping continues to grow, returns operations, while more critical than ever post-holiday season, are struggling to keep up.

“By applying robotic automation to optimize reverse logistics processing, e-commerce retailers and 3PLs have an opportunity to change the equation for e-commerce returns and turn a negative into a positive.”

Consumers expect free, no-hassle returns for their online purchases. Those ‘easy’ returns have been a major driver for e-commerce growth, especially in categories such as apparel, footwear, electronics, and luxury items.

But for e-commerce retailers, returns processing is neither free nor easy. The average cost of an e-commerce return, regardless of item value, ranges from $20.75 to $45.25 when factoring in the costs of transportation, processing, and markdowns/liquidation to resell.

To reduce the impact of these costs, retailers need to focus efforts on increasing the resale of previously purchased goods.

“A great reverse logistics supply chain can be a valuable profit contributor to a retail company through its ability to optimize the resale of returned merchandise at full price,” according to a Gartner report.

Berkshire Grey says its Reverse Logistics solution helps decrease markdowns by speeding up returns processing to get goods back into inventory or moved to refurbishment up to 25 percent faster than manual processing.

In addition, the solution reduces processing costs by improving labor handling efficiency by up to 35 percent.

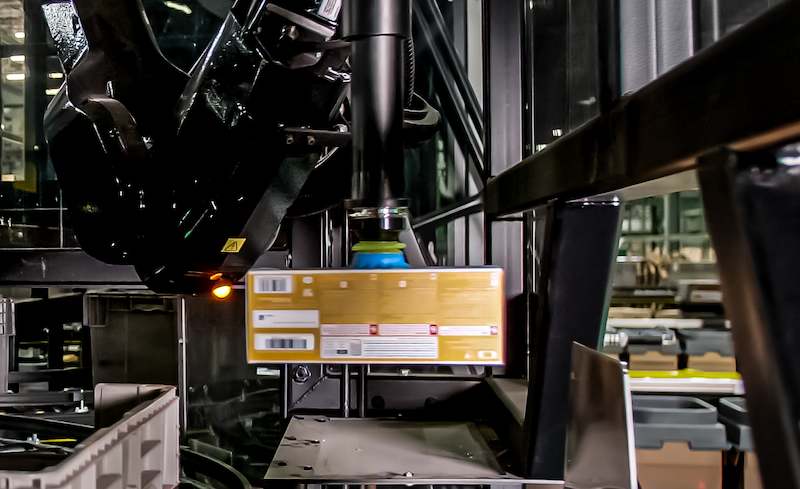

The Reverse Logistics solution includes Berkshire Grey’s Robotic Product Sortation with Identification (RPSi) and Robotic Shuttle Put Wall (RSPW) systems, both of which are specifically configured to efficiently process returns.

BG RPSi systems allow 3PLs and other central returns processing centers to pre-sort incoming packages by brand and merchandise category prior to opening and inspecting the merchandise.

BG RSPW systems will rapidly sort returned products for faster put away to resell and/or refurbish.

Both systems improve labor utilization and speed up the overall returns handling process to make returns less costly and ultimately more valuable to sellers.