John Deere is leveraging Intel’s artificial intelligence technology to help solve a costly, age-old problem in the manufacturing welding process.

Deere is piloting a solution that uses computer vision to automatically spot common defects in the automated welding process in its manufacturing facilities.

Andy Benko, quality director, John Deere construction and forestry division, says: “Welding is a complicated process. This AI solution has the potential to help us produce our high-quality machines more efficiently than before.

“The introduction of new technology into manufacturing is opening up new opportunities and changing the way we think about some processes that haven’t changed in years.”

Why it matters

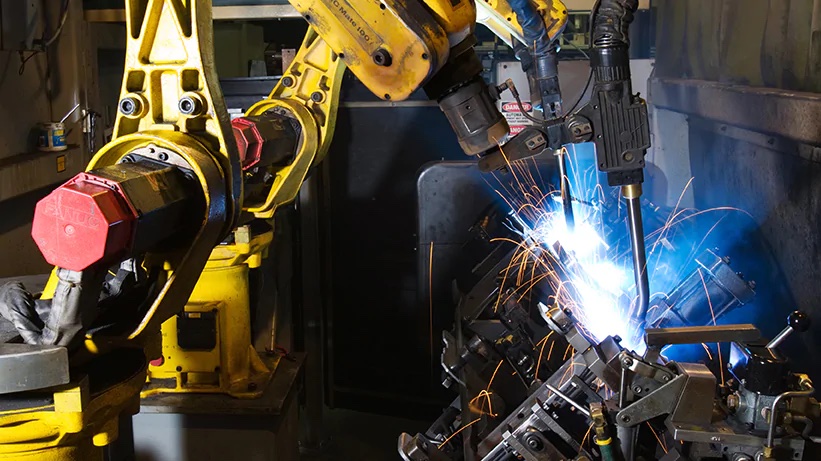

At 52 factories around the world, John Deere uses the Gas Metal Arc Welding (GMAW) process to weld mild- to high-strength steel to create machines and products. In these factories, hundreds of robotic arms consume millions of weld wire pounds annually.

With this volume of welding, Deere has experience finding solutions to welding issues — and is always looking for new ways to deal with potential problems.

One common welding challenge felt across the industry is porosity, in which cavities in the weld metal are caused by trapped gas bubbles as the weld cools. The cavities weaken the weld strength.

Traditionally, GMAW defect detection has been a manual process requiring highly skilled technicians. Past attempts throughout the industry to deal with weld porosity issues during the welding process haven’t always been successful.

If these flaws are found later in the manufacturing process, they require re-work or even scrapping of full assemblies, which can be disruptive and expensive to manufacturers.

How it works

The opportunity to work with Intel to leverage AI to address weld porosity was a chance to bring together two of John Deere’s core values — innovation and quality.

“We wanted to drive technology to make John Deere’s weld quality better than it’s ever been. That’s the commitment we have to our customers, and that’s what they expect from John Deere,” said Benko.

Intel and Deere combined expertise to develop an integrated, end-to-end system of hardware and software that can generate insights in real time at the edge, at levels beyond the human sense’s capability.

When using a neural network-based inference engine, the solution logs defects in real time and automatically stops the welding process. The automated system allows Deere to correct the issue in real time and produce the quality products that Deere is known for.

Christine Boles, vice president in Intel’s internet of things group and general manager of industrial solutions group, says: “Deere is leveraging AI and machine vision to solve a common challenge with robotic welding.

“By leveraging Intel technology and smart infrastructure in their factories, Deere is positioning themselves well to capitalize not only on this welding solution, but potentially others that emerge as part of their broader Industry 4.0 transformation.”

About the solution

The AI defect detection at the edge solution is powered by Intel Core i7 processors and uses Intel Movidius VPUs and the Intel Distribution of OpenVINO toolkit, implemented with an industrial-grade ADLINK Machine Vision Platform and a MeltTools welding camera.