Festo is looking to implement artificial intelligence systems to make automation even more productive and efficient.

The company says it currently offers intelligent component and process monitoring. But Festo intends to further increase the productivity of its customers by means of self-learning machines.

The company is relying here on AI at three network levels:

- on edge;

- on premises; and

- in the cloud.

In addition to the complex services that can be offered in a cloud, Festo sees great potential in simple real-time data analysis by means of AI – either directly on the field component (AI on edge) or in the control of either the system or a production plant (AI on premises).

The plant operator retains full control of his or her machine data, which do not need to be transmitted to a cloud via the Internet.

At the recent Hannover Messe 2019 trade fair, Festo used two exhibits to demonstrate how systems can autonomously find solutions to problems based on available data.

Intelligent process monitoring in battery production

Festo further extended its AI competence with the acquisition of Resolto Informatik GmbH in April 2018.

With Scraitec, Resolto has developed a software solution that analyses and interprets data in real time and recognises and reports anomalies.

The system also constantly learns by means of permanent data analysis and expands its knowledge base. This machine learning makes intelligent process monitoring possible.

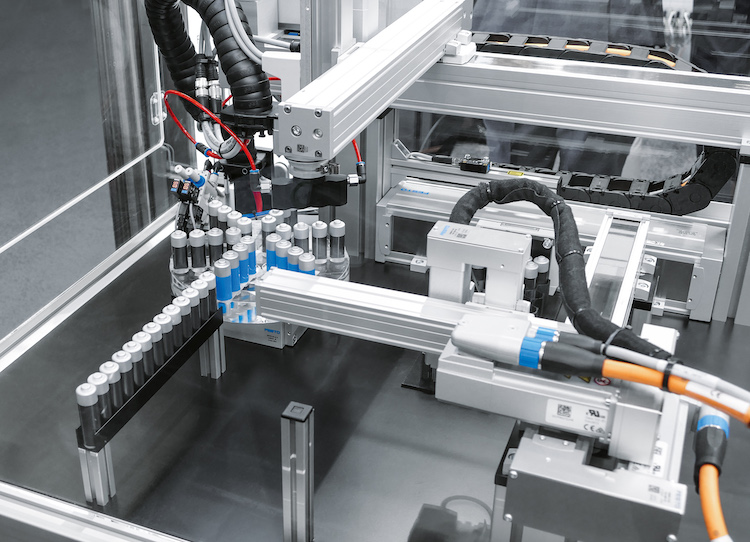

Visitors to the trade fair can experience this software solution live at the booth of Festo. The application demonstrates the detection of faulty batteries.

The batteries are lifted by a handling gantry. In combination with the new CPX-E-CEC modular control and the new CMMT-AS servo drive controller, surveillance is possible in real time

. The Resolto monitoring software oversees the engine currents and the positional parameters of the axis. If anomalies occur, for example if the handling unit grasps the wrong battery format, a report is issued.

The acquisition and monitoring of data by the intelligent software solution can be carried out either on edge or on premises, or via the IoT gateway CPX-IOT in the Festo Cloud.

The use of AI on edge or on premises ensures that all data remain in-house, without security risks or delays in data streams due to network latency.

It is important that sufficient structured data are available so that meaningful analysis can be carried out using AI as a tool.

With its very high computing capacities, the cloud in turn provides good evaluation results spread over several distributed production locations.

AI greatly reduces the programming effort for process monitoring and error management, and the customer is provided with valuable know-how in real time.

Faulty parts and processes, or machine failure, can be detected and prevented at an early stage in the production process.

A further advantage is the complete transparency and traceability of process anomalies to a specific manufactured part. Large-scale product recalls affecting entire production series could be avoided in future, since a faulty part can be precisely identified and removed from the batch.

Intelligent component surveillance in the CMMT unit: AI in the cloud

The exhibit shows how a learning algorithm is used for fault monitoring of components. Data from an electrical axis are recorded and collected by the CMMT controller.

The surveillance algorithm and the monitoring of the collected data are carried out entirely within the Festo Cloud. The data are therefore available at any place and any time.

However, customers benefit not only from the reduced programming effort. The normal conditions of their individual processes are fed into the learning algorithm during operation or in the form of historical data.

The data can be immediately evaluated via the cloud. Users can thus rapidly recognise any deviations and directly trace the causes of faults. Exchange components can also be quickly identified.

This saves time, reduces downtimes and lowers maintenance costs. It is conceivable that component groups such as modules, systems or entire machinery units could also be monitored by this means in future.