ABB finalizes acquisition of Sevensense

January 25, 2024

Epson’s makes latest SCARA Robots available to market

January 19, 2024

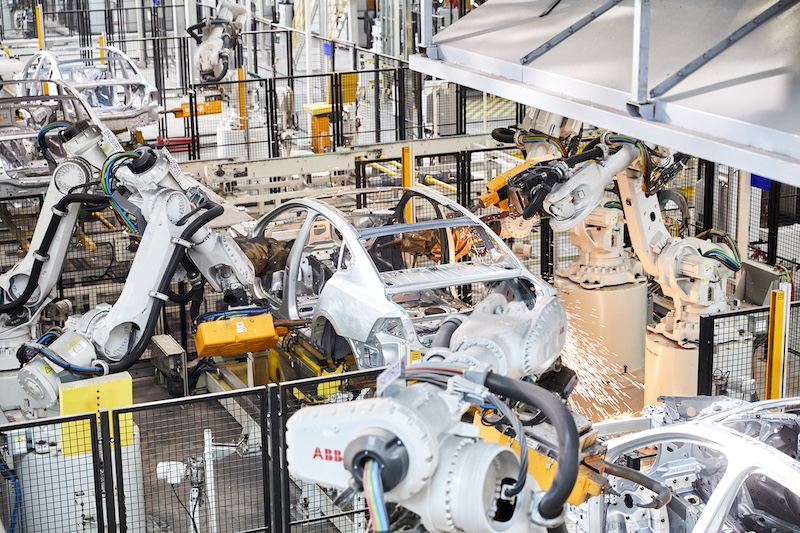

ABB to supply over 1,300 robots to Volvo Cars

January 16, 2024

Universal Robots doubles UR20 production ‘due to demand’

December 17, 2023

Epson introduces new class of SCARA robots

November 3, 2023