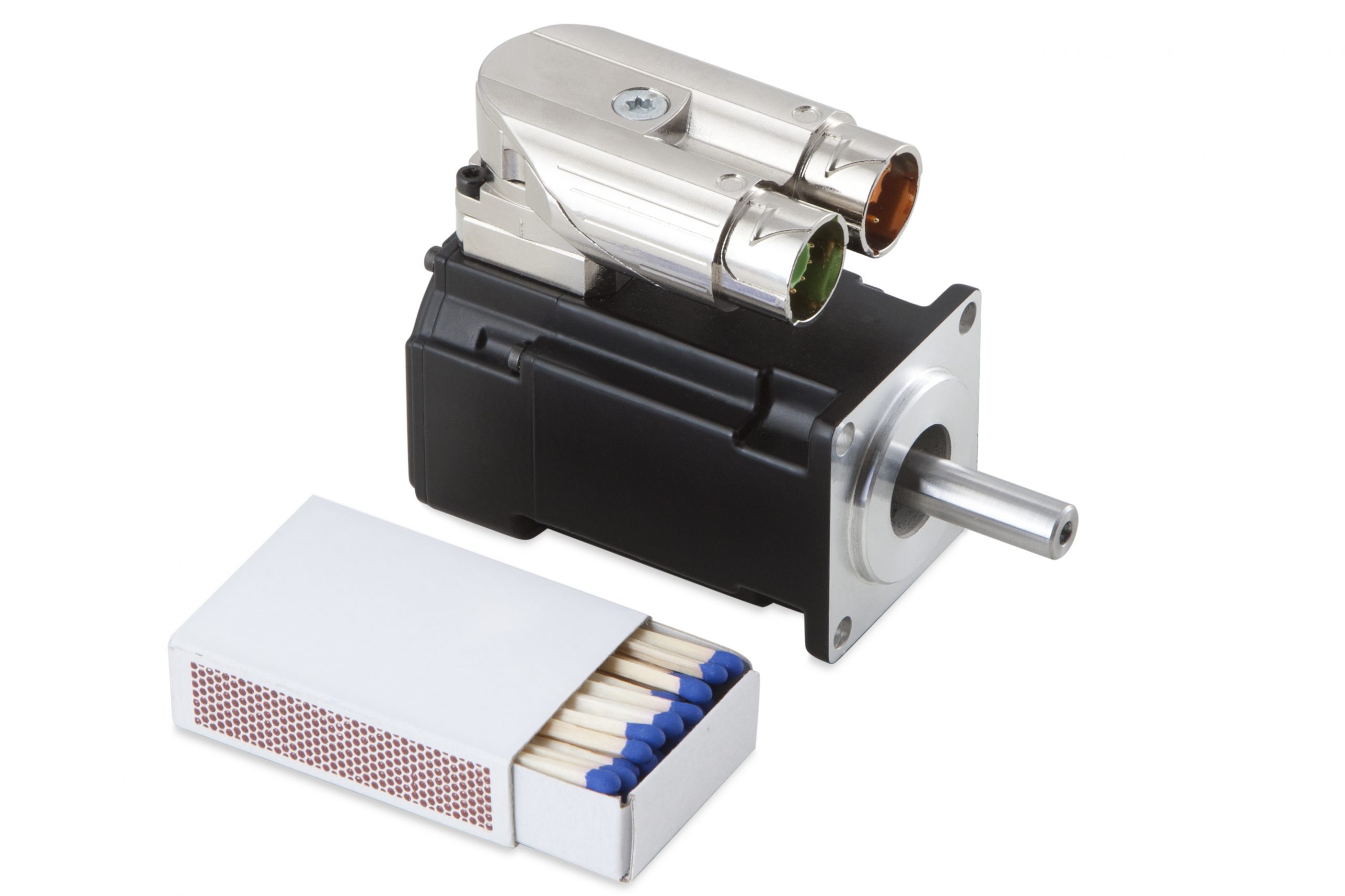

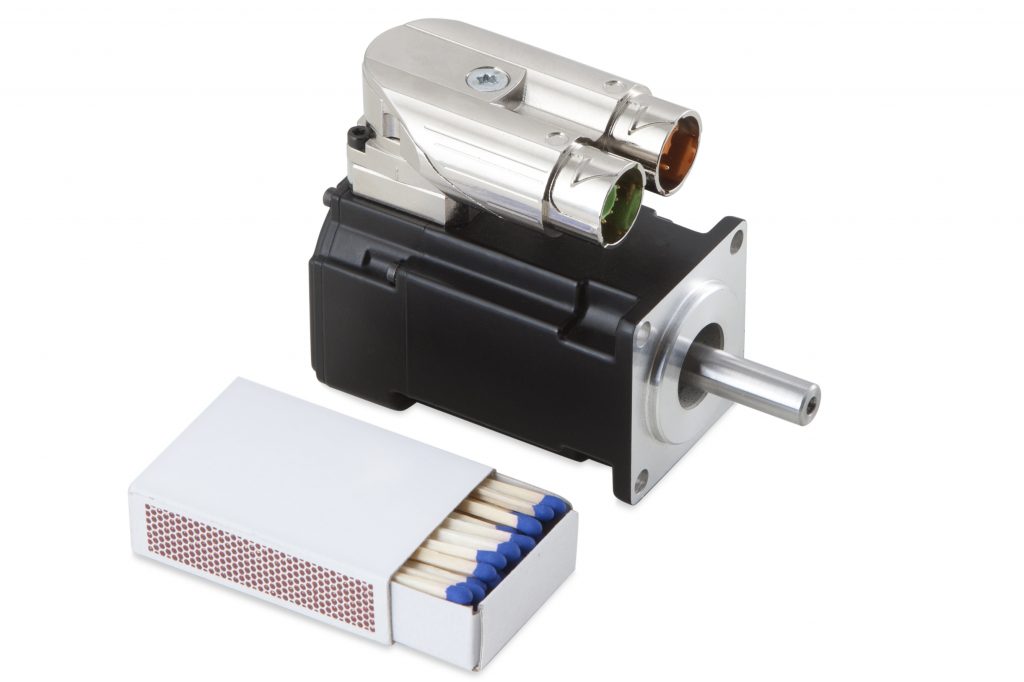

Kollmorgen expands its AKM servo motor series

Kollmorgen says its new servo motor has energy efficiency, durability, power density, overload capability, and – crucially – is extra low voltage.

The new AKM DC servo motor low voltage with its 48-volt design was originally intended as a customer-specific solution for special areas of use.

Kollmorgen, a specialist in servo-drive technology and motion control will now offer this as a standard add-on to the AKM series, and thus as a new series product.

There are many potential uses for 48 volt DC servo motor low voltage. The same applies to two new variants with a 24 volt power supply.

Size 3 AKM low voltage servo motors of 48 volts provides up to 300 watts of power at a current of 6 A – sufficient, for example, for accurate drive tasks in packaging machines or for dynamic movement in autonomous transport systems.

Because the axes can briefly provide a peak current of up to 15 A, the breakaway torques predominant on start-up are easily overcome, which, at the end of the day, prevents permanent over dimensioning of the drive technology.

The static torque is 1.25 Nm with an impulse torque of 4.1 Nm. Further variants of Kollmorgen AKM low voltage DC servo motor include two 48 V motors with less power, and two drives with windings tailored to 24 volts.

The company says that thanks to its compact form, the extra low voltage servo-axis can be very easily retrofitted in existing installations and additionally allows space-saving surface mounting of machine modules with autonomous intelligence – in the form of a labeling unit, for example.