ABB Robotics is demonstrating what it describes as “the next leap in automated laboratory workflows”, showcasing how AI-powered, Autonomous Versatile Robotics (AVRTM) can deliver higher throughput, improved reproducibility and seamless multi-vendor connectivity.

ABB Robotics is at Booth #2027 at the ongoing Society for Laboratory Automation and Screening (SLAS) 2026 International Conference & Exhibition, February 7-11 at the Thomas Michael Menino Convention & Exhibition Center in Boston.

Jose-Manuel Collados, service robotics product line manager at ABB Robotics, says: “Laboratories worldwide are moving from isolated automation pilots to fully connected, AI-ready operations.

“At SLAS 2026 we will show how ABB Robotics and its partners are helping customers make that transition – combining more autonomous and versatile collaborative robots with interoperable solutions that seamlessly connect instruments, data and digital tools.

“This is enabling labs of every size to scale faster, work more reliably and capture deeper insights from every experiment.”

Highlights of ABB’s participation include three comprehensive collaborative robot laboratory process cells, displaying how scientists can automate more steps, capture richer data and scale operations with greater confidence.

Working with leading laboratory instrument and automation software providers such as Agilent and Mettler Toledo, the workflows illustrate how advanced automation enhances throughput and reproducibility, strengthens traceability and frees researchers to focus on higher-value scientific work.

Demonstrating next-generation interoperability

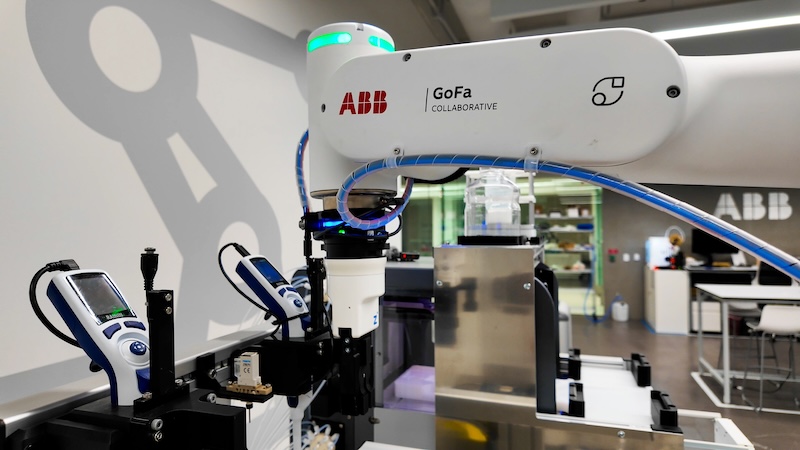

ABB Robotics’ SLAS demos also focus on the power of open, interoperable automation. Using ABB’s GoFa 5kg payload collaborative robots, the workflows will show how customers can combine robotic technologies with specialized instruments and software from a variety of vendors to build flexible, scalable and tailored automation systems.

The following two demos are taking place at the ABB Robotics Booth (#2027):

- A multi‑step analytical workflow system with Mettler Toledo instruments orchestrated via LabX management software, including liquid and solid sample prep, weighing, titration, oven cycling, and UV‑Vis analysis. An ABB Robotics GoFa autonomously will perform functions such as pipetting, decanting, and vial capping/uncapping, providing improved process consistency and increased lab operator walkaway time.

- A comprehensive Gas Chromatography (GC) sample‑prep flow, with GoFa executing automated solid dispensing, volumetric flask handling, filtration into 2 mL vials, and GC loading, plus a reset cycle demonstrating reliable end‑to‑end robotics for complex, mixed “dry” and “wet” tasks. The demo also features ABB Robotics OptiFact™, an all-in-one software platform designed to collect, manage, and analyze facility data.

A third demo will be at the Agilent booth (#1808):

- Showcasing an ABB Robotics and Agilent collaboration on the robotic transfer of SBS/SLAS plates and consumables between a plate hotel, an Agilent Bravo deck, and High-Pressure Liquid Chromatography (HPLC) integrated with a Bravo liquid handler in pick and place mode.

The cell reflects the seamless integration of ABB Robotics and Agilent equipment, and replicates the validated motion path, underscoring repeatable, high throughput handling that complements existing instrument operations, ensuring the most accurate lab results.

Together, these demos will show ABB robots working across Mettler Toledo and Agilent ecosystems to streamline sample prep and analysis, improve repeatability, and free scientists to carry out higher value work, while offering a realistic vision of the lab of the future.

Roundtable discussion

On Tuesday, February 10, from Noon to 1:15pm EST (Room 107A), ABB Robotics will host a roundtable entitled “From Insight to Impact: AI, Robotics and the Convergence toward the Lab of the Future”.

The session will bring together experts from Atinary, Agilent, Mettler Toledo, Sanofi, and ABB Robotics to discuss how AI, robotics and interoperable platforms are reshaping laboratory operations.