ABB has introduced a new automation architecture called Automation Extended, designed to help industrial operators upgrade their control systems while avoiding costly shutdowns and large-scale equipment replacements.

The program builds on ABB’s installed base of distributed control systems (DCS) and aims to provide a structured path for companies to adopt newer digital technologies – including artificial intelligence, advanced analytics, and Internet of Things connectivity – without interfering with mission-critical operations.

Industries such as energy, chemicals, mining, and utilities are under increasing pressure from volatile markets, cybersecurity risks, regulatory demands, and workforce changes. ABB says its new approach allows operators to modernize gradually while preserving existing infrastructure.

Operators will continue using established ABB platforms such as ABB Ability System 800xA, ABB Ability Symphony Plus, and ABB Freelance, while introducing additional technologies over time.

Peter Terwiesch, president, ABB’s Automation business area, says: “In industries we serve – many operating large and complex infrastructures that deliver essential resources – our customers rely on modernization without disruption.

“Automation Extended delivers exactly that: bringing future-ready capabilities into the systems they know and trust, with security and interoperability at the core.”

Separating control from digital innovation

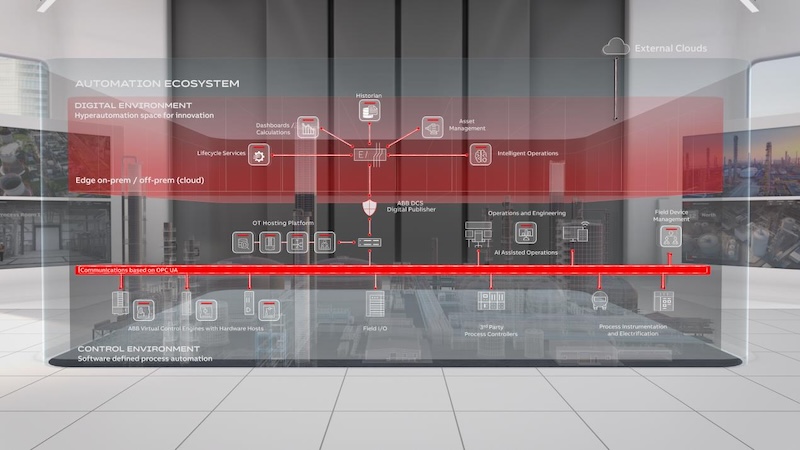

At the center of Automation Extended is an architectural model that separates critical control functions from newer digital applications.

The control environment is described as a “software-defined domain” responsible for maintaining deterministic performance in essential processes.

Alongside it sits a securely connected digital environment, where advanced applications – including AI and machine learning tools – can support decision-making without altering proven control structures.

ABB says this separation allows companies to deploy new capabilities at scale while reducing operational risk.

Open and modular architecture

The automation ecosystem is built around an open and modular framework intended to support interoperability across industrial systems.

According to ABB, the architecture incorporates technologies such as Open Platform Communications Unified Architecture (OPC UA) and cloud-native infrastructure using containerization and modular services.

These tools are expected to enable capabilities such as anomaly detection, condition monitoring of critical assets, maintenance optimization, and more efficient engineering workflows.

ABB also plans to provide a unified lifecycle service model to support deployment, management, and long-term system performance.

Modernization without replacement

Large industrial facilities often hesitate to replace control systems because of the potential for downtime and operational disruption. ABB positions Automation Extended as an alternative to so-called “rip-and-replace” upgrades, allowing operators to extend the life of existing assets while adding digital functionality.

The company says the approach is intended to deliver greater scalability and agility while maintaining robust performance in environments where reliability is essential.