Roll diameter is an important factor in a lot of industries that deal with storage, shipping, and performance.

It has an effect on everything in the process, influencing storage efficiencies and shipping logistics, as well as product performance.

Understanding the roll diameter’s impact helps businesses understand how it should be handled and what type of process should be followed to have maximum efficiency throughout.

Maximizing Storage Efficiency

Bigger diameters of the roll need a larger storage space. This forces all warehouses to provide even more space just to fit the larger size, which may, in turn, reduce the number of rolls stored at a time.

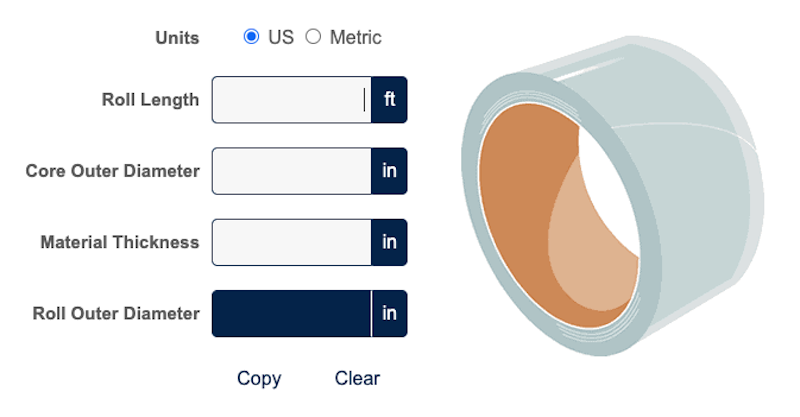

In contrast, smaller-diameter rolls enable denser stacking and easier organization. Businesses wanting to optimize their warehouse space can use a roll diameter calculator to evaluate how the dimensions of the roll relate to the area of the warehouse floor.

With this, the area will be utilized better, and stock flow will be easier to manage.

Enhancing Shipping Logistics

Shipping price is primarily dependent on size and weight. A thicker roll will have a larger roll diameter, which in turn occupies more space in the cargo and reduces the number of products that fit into one shipment.

When carriers have to ship larger items, shipping costs increase. Rolls with lower diameters will allow for tighter packing inside the shipping container, reducing the number of truck trips for deliveries.

Using this method can result in significant savings over the long run, particularly for businesses that ship large volumes.

Improving Handling and Safety

These oversized rolls can be problematic for loading and unloading. Lifting heavy or bulky items exposes employees to a greater danger of injury and often requires special tools.

In contrast, small rolls are easier to lift and to handle manually, which reduces the risk of workplace accidents.

Using the correct roll diameter ensures workplace safety without compromising productivity. Fewer risks translate to less downtime for the company and less health-related expenses for the employer.

Affecting Material Performance

The roll diameter affects the unwinding process and ultimately, the performance of your materials in use. When it is wound tightly in large rolls, additional stress can be placed on the inner layers, which can cause it to deform and wrinkle.

This is especially applicable to materials like films, foils, or textiles where surface quality is critical.

Smaller rolls mean less tension on innermost layers, which helps protect product integrity, enabling reduced waste. Better unwinding would lead to less maintenance, less production downtime, and happier customers.

Impact on Production Processes

Many machines need rolls of a specific size. Too big a roll may not fit on available equipment, resulting in expensive alterations or new buys.

However, smaller rolls can typically be integrated with the majority of standard machines, enhancing production efficiency and minimizing downtime for maintenance.

Choosing the appropriate diameter enables optimal working and helps avoid delays in the process. Reduced stoppages help companies maintain their performance stability.

Environmental Considerations

A smaller roll diameter takes into account sustainability targets. Tighter rolls can easily need less packaging material, which reduces waste and decreases disposal costs.

Smaller rolls allow for more efficient shipping, which reduces emissions and fuel consumption during transport.

These practices allow for environmentally conscious operations and commitment to greener measures. Those organizations that take such measures may also enjoy positive public perception.

Cost Implications

The financial implications of roll diameter are something that material suppliers and manufacturers have to think about in their processes.

Big rolls may look as if they save money by reducing changeovers, but higher storage and shipping costs can negate those savings. Handling more frequent, smaller rolls may appear to be more hectic, but it has logistics and safety advantages.

A thorough examination of overall costs allows the organization to see the most affordable solution for them. By factoring in these details, better resource allocation is possible.

Maintaining Product Consistency

Constant material delivery during processing is guaranteed by the uniformity of the roll diameter. Scale differences trigger malfunctioning, errors, or quality issues in automated systems.

Keeping the diameter standard helps in seamless operations and predictable results. Standard verification and validation avoid bigger mistakes and meet customer requirements.

Conclusion

Everything from storage and transportation to performance and environmental impact is affected by the roll diameter.

Careful choices about size can create safer work environments, save money, and result in better products.

All these factors affect organizational efficiency, and companies take note of these and enhance their processes to achieve success and set better relationships with their customers.