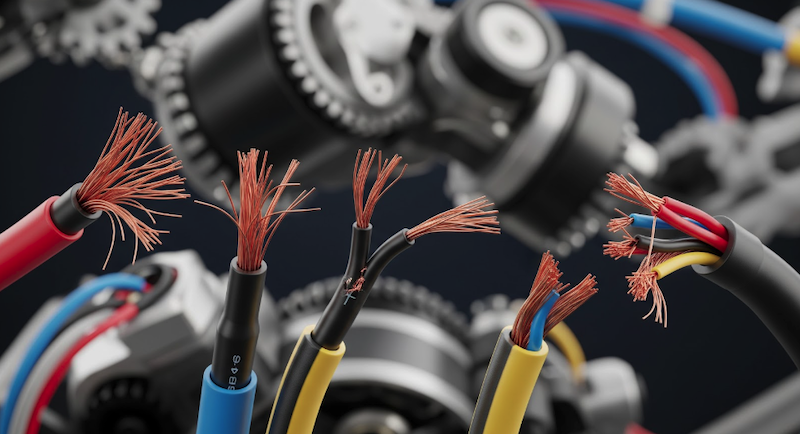

If you have ever dealt with robotic systems, you know cables are something you cannot live without and at the same time you hate them so much. They are the lifelines that operate the motors, transmit and ensure that everything works well.

However, these cables are beaten up when robots are in motion, maybe it is a robotic arm on an assembly line, an autonomous guided vehicle (AGV) dashing about a warehouse or the joints of a humanoid robot moving their parts about in unusual manners.

Cable breakdowns can cause your whole business to come to a standstill, time, money and a hundred headaches.

Understanding Why Cables Fail in the First Place

It is important to consider the causes of cable failures in robotic applications and then discuss solutions. The most frequent offenders are:

- Mechanical stress: Due to recurring bending and flexing.

- Abrasion: Due to rubbing against surfaces or other cables.

- Torsional stress: Due to twisting movements.

- Environmental conditions: Such as temperature extremes, dust, or chemical contact.

Cables on a moving robot undergo what is known as dynamic flexing, which is quite unlike when used in a fixed electricity installation in a building. Each cycle puts stress on the conductors and the insulation, and with thousands or millions of cycles, even the finest cables could not do it, unless they were constructed to do the work.

Begin with the Right Cable Design

The basis of avoiding cable failures is the selection of cables that are specially designed to be used dynamically. Cables are not all equal and when it comes to high-flex applications it is just a matter of time before using standard cables becomes a problem.

Conductor Selection

Find cables which are built with fine-stranded conductors instead of solid or rough-stranded conductors. The finer the stranding the more pliable the cable and the more it can be bent several times.

A large number of specialized cables contain conductors whose stranding classes are five or six, or higher where a very high level of flex is required.

Insulation and Jacketing

The insulation medium also counts a lot. Materials such as polyurethane (PUR) and thermal plastics elastomers (TPE) are highly flexible and durable as opposed to the normal standard PVC.

They are resistant to abrasion, do not lose their properties in the broad temperature intervals, and can be subjected to the continuous movement without being cracked or disintegrated.

It can be a difference in working with a reputable Cable Assembly Manufacturer that are familiar with particular requirements of robots application.

They may assist you in choosing or designing their own cables that perfectly fit your movement profiles and environmental needs.

Pay Attention to Cable Routing and Installation

Even the best cable won’t last long if it’s installed incorrectly. The method of laying in cables through your robot will greatly affect the life of the cable. The important factor is to ensure reduction in stress and strain on the cables in their movement.

- Internal Routing: In the case of robotic arms, this usually involves running cables along the inner part of joints as opposed to the exterior where the cables are more subjected to radical bending.

- Cable Carriers: Controlling cable motion within linear tasks such as gantry installations or AGVs with sliding mechanisms is one of the most useful methods by the use of cable carriers or energy chains.

These guides provide a consistent radius of bend, eliminate instances of tangling, twisting too much or scratching on sharp surfaces. Cables should be installed with the minimum bend radius specifications of the manufacturer taken into consideration.

Excessive sharp bending of cables even when installing them may destroy the inside structure, and cause early breakdown. Cables should also be fixed well without tightening clamps or zip ties, which may form stress focus points. Imagine your cables to be parts of your robot that require space and air to breathe.

Consider Cable Construction Details

In addition to deciding the selection of your basic materials, how your cables are built internally is also a determining factor as far as longevity is concerned.

- Internal Geometry: Robotically-use cables may have special constructions such as spiral or twisted pair cable forms in which the stress is more balanced during bending.

- Reinforcement: Others, such as high-end cables, incorporate such reinforcement layers as aramid fibers or braided shields, which offer mechanical support without sacrificing flexibility. These advanced robotics cable assembly designs are built to survive millions of flex cycles without degradation.

- Outer Protection: The outer jacket must be durable so as to withstand abrasion and damage to the environment but must be flexible.

Quality manufacturers are particularly careful in strain relief of connection points during the process of the Wire Harness Production where most cable failures actually take place.

When substituting the flexible cable body with rigid connectors it provides a weak point and hence requires strain relief boots, molded connections or purposefully designed backshells.

Maintenance and Monitoring: Don’t Forget About Maintenance and Monitoring

Although selecting and installing the cables is perfect, it is important to maintain the equipment to ensure that the issues are detected before failures occur. Have regular cable checks, particularly in high-cycle places.

Signs to watch for:

- Abrasion marks.

- Cracking of the outer jacket.

- Alterations in flexibility.

Most facilities do not find out there is a problem with their cables until they fail completely, however by conducting a proactive check-up you would be able to replace your cables during scheduled maintenance and not an emergency downtime where it would need to cost the company a lot of money.

In case of critical applications, it is better to use cables with inbuilt monitoring potential or use thermal imaging inspection which is able to identify hot spots that signify electrical resistance caused by damaged conductors.

Custom high-tech robots have been developed with predictive maintenance software, which tracks the electrical properties and notifies the operators to degradation in time before failure.

Work with Experienced Partners

It is not only about purchasing costly cables, but rather a matter of knowing what needs to be done in a particular application, and adopting a holistic strategy.

Collaborating with qualified suppliers specializing in the industrial and robotic applications can also be an eye opener that you otherwise would not learn independently.

Professional providers and firms such as WellPCB Spain tend to possess engineering staff that would be able to assess your robot movement patterns, the environmental factors, and the performance needs, in order to suggest the best solutions.

They are also able to assist with testing and verification which will ensure your cable selections will actually make you the lifetime needed before you invest in large scale implementation.

Conclusion: A Holistic Approach Wins

There is no single magic bullet to minimize the cable failures during the mobility robots movement but the combination of wise choice of cables, intelligent routing and installation methods, manufacturing quality and maintenance can help to reduce the number of failures.

With careful attention to all of these factors, you can significantly increase cable life, minimize downtimes and ensure that your robotic systems do not run afoul.