By 2025, the vocabulary of the plant floor has changed. “Downtime” is being replaced by “predictive interventions,” “batch records” by “digital thread,” and “gut feel” by “data-driven decision.”

What sits behind the new language is a maturing wave of smart manufacturing technologies that are quietly lifting output, squeezing costs, and protecting margins in a stubbornly volatile market.

This article is written for manufacturing leaders, operations managers, and industrial engineers who need a straight-talking tour of where the biggest efficiency gains from technology solutions for manufacturing are actually coming from and how to capture them without derailing ongoing production.

We will zero in on three technology domains that consistently move the dial: digital twins, edge-based AI quality monitoring, and connected-worker platforms. Then we will wrap up with a pragmatic roadmap you can start using Monday morning.

Why Smart Manufacturing is No Longer Optional

Five years ago, smart manufacturing was often filed under “strategic initiative.” In 2025, it migrated to the column labeled “license to operate.”

According to Deloitte’s 2025 Smart Manufacturing Survey, 92% of manufacturers already consider it the primary driver of future competitiveness, and some have active or imminent projects underway. The reason is simple: proven, bankable results.

- Companies that embed IIoT sensors and real-time analytics are reporting 10-20% increases in production output and up to 35% cost reductions.

- Digital-twin adopters are trimming commissioning times by 60% and freeing some latent capacity in existing assets.

For leaders wrestling with persistent labor shortages, energy volatility, and skeptical boards, those numbers translate into the difference between hitting quarterly targets or writing uncomfortable shareholder letters.

Digital Twin: The New Virtual Powerhouse

The phrase “single source of truth” is thrown around liberally, but a well-built digital twin comes close. Think of it as a living, breathing replica of an asset, a line, or even an entire plant that stays in sync with physical reality minute by minute.

From Design Sandbox to Daily Optimization

When executing greenfield projects, the twin allows the process engineers to make the greenfield a risk-free sandbox where they can simulate changes in recipes, equipment updates, or operator processes without investing a dollar in the real world.

Once the line is running, the same model ingests live sensor data, letting algorithms spot drift and automatically nudge settings back inside the sweet spot.

Practical implementation tips:

- Start with a critical bottleneck asset rather than the entire plant. The narrower scope accelerates ROI and helps build organizational confidence.

- Prioritize data pipelines (OT and IT connectivity) over 3-D visuals. A pretty model that lacks reliable real-time data is an expensive screensaver.

- Make the twin bidirectional. Integration with the control layer (for example, via OPC UA and the MES) lets recommended set-point changes flow back automatically, closing the loop.

Digital twins rarely work in isolation. They perform best when paired with complementary smart manufacturing technology, such as edge AI and advanced manufacturing technologies like additive and generative design, which can feed new design variants directly into the simulation environment.

Edge AI for Real-Time Quality Surveillance

Sending every data point to the cloud is neither fast nor cheap when milliseconds matter. That is why edge AI, deploying machine-learning models on or near the machine, has become one of the hottest technology solutions for manufacturing.

Putting Intelligence Where the Action is

Vision systems mounted above high-speed conveyors can now run convolutional neural networks directly on industrial PCs or embedded GPUs.

Instead of a yes/no decision, the model can grade defects, predict the type of corrective action required, and cue the operator via an augmented-reality (AR) headset while the part is still in the workstation.

Lessons learned from early deployments:

- Model maintenance is at least 50% of the effort. Edge devices need periodic updates as new part numbers or materials are introduced.

- Latency budgeting matters. Aiming for sub-100 ms round-trip (camera → GPU → actuator) prevents line slowdowns.

- Collaborate with IT on device management from day one. Forgotten edge nodes become security blind spots.

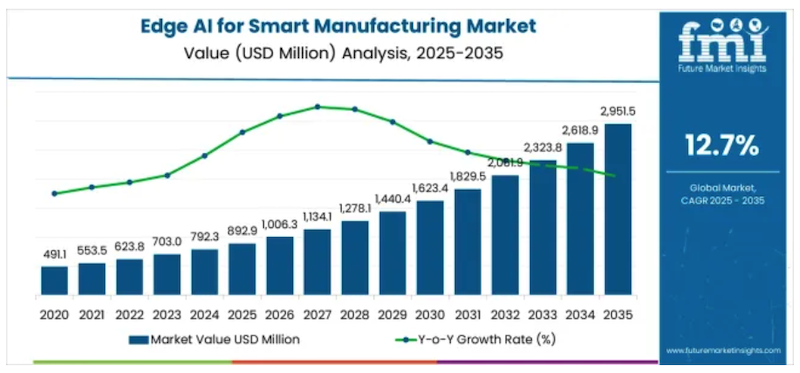

Market analysts value the edge-AI-for-smart-manufacturing segment at roughly $893 million in 2025 and forecast a 12.7% CAGR through 2035.

That growth is being driven not by hype but by hard savings: fewer inspectors, tighter process control, and real-time feedback loop integration with MES and supervisory control systems.

Connected-Worker Platforms and Augmented Reality

Efficiency is not just about machines; it is about the people who keep them running. Connected-worker platforms combine wearable devices, contextual data, and standardized digital procedures to shrink the gap between novice and veteran technicians.

Consider a food-processing facility where the average operator tenure has fallen below three years. With paper SOPs, line changeovers dragged to 50 minutes.

After rolling out AR headsets that overlay step-by-step instructions – pulling torque specs, bill of materials, and safety checks from a central content hub – changeovers stabilized at 32 minutes, and first-pass yield actually rose because fewer setup mistakes slipped through.

Key success factors include:

- Content governance. A digital work instruction is only as good as its last revision. Assign owners and embed review cadences.

- Usability. Field-of-view, battery life, and glove-friendly controls determine whether operators embrace or bypass the tech.

- Integration. Bi-directional links to CMMS and QMS close the loop from work execution back to asset history and compliance records.

Combined with other intelligent manufacturing solutions, including edge AI indicating a quality anomaly, connected workers can also get real-time alerts to modify the parameters or trigger a just-in-time maintenance process. The synergy transforms individually discrete data into concerted performance.

A Pragmatic Roadmap to Capture Value

Buzzwords are cheap; sustainable results are not. Below is a condensed blueprint that blends lessons from high-performing plants into a sequence most organizations can replicate.

1. Anchor on a Business Problem, Not a Technology

Is it a chronic throughput on a filler, an uncertain scrap on a die-cast machine, or is it an impending energy-saving goal that makes the pain actual?

Then project that pain on map technology enablers (digital twin, edge AI, connected worker). Such alignment puts a check on scope creep and assists in financing by balancing costs versus benefits.

2. Secure a Clean Data Foundation

It is trying to put advanced manufacturing technologies on the dirty data, just like pouring fine gasoline in an engine full of rust. Make certain of sensor accuracy, consistency of tags, and availability of historians. A one-time data cleanup sprint often pays for itself via faster troubleshooting long before AI shows up.

3. Pilot Fast, Scale Faster

Success metrics should design pilots to achieve a go/no-go decision in four months. The success metrics must have a quantifiable operational KPI (OEE, scrap rate, or energy per unit). Learnings capture, technology stack standardization, and rollout to sister lines without having to re-invent the wheel.

4. Upskill People in Parallel

Smart manufacturing technology does not eliminate the need for human judgment; it elevates it. Budget for training hours, digital badges, and time for “citizen data scientists” to experiment. Plants that neglect this step often watch technology adoption stall at the pilot stage.

5. Govern, Measure, Repeat

Create an executive steering rhythm that has responsibility for value capture. Pilot ROI Standing dashboards linking corporate KPIs to pilot ROI maintain the momentum and corporate budgets against economic headwinds.

Following this roadmap does not require moonshot investments. Many plants unlock double-digit efficiency gains within 12 months simply by combining existing data, targeted analytics, and disciplined change management. The trick is to resist the lure of sprawling, multiyear transformations and instead focus on sequenced learning cycles.

Conclusion: Efficiency is Becoming Predictable if You Act

In 2025, production efficiency is no longer an arms race of bigger presses or faster robots. It is an information game dominated by organizations that fuse data, models, and human insight into a continually optimizing system.

Digital twins create the virtual testbed; edge-AI quality systems guard output in real time; connected-worker platforms turn every technician into a walking knowledge node. Together, these smart manufacturing technologies form a backbone that quietly compounds advantage shift after shift.

Manufacturers that move now will not just cut scrap or shave energy bills. They will hard-wire agility into their DNA, ready to pivot whether the next shock is a raw-material spike or a fresh compliance mandate. Those who wait risk discovering the plant floor has become a landscape of haves and have-nots, and catching up in a down market is never cheap.

For leaders evaluating their next investment cycle, the take-home message is clear: start with a pressing business problem, secure reliable data, and let targeted technology solutions for manufacturing do the heavy lifting. Efficiency, once elusive, is becoming predictable. The only variable left is how quickly you decide to capture it.