The reshoring of manufacturing in the United States has intensified over the past few years, driven by supply chain shocks, geopolitical tensions and the growing economic pressure on companies to bring production closer to home.

Yet one challenge continues to frustrate even the best-intentioned reshoring plans: precision manufacturing still relies heavily on skilled manual labour, and the talent pipeline is shrinking faster than new facilities can hire.

Into this environment steps Zheng Xu, co-founder and CEO of Ebots, a newly launched robotics and AI company aiming to bridge that gap.

Ebots positions itself not as another incremental automation supplier but as a platform designed to make high-precision manufacturing economically viable in the US again.

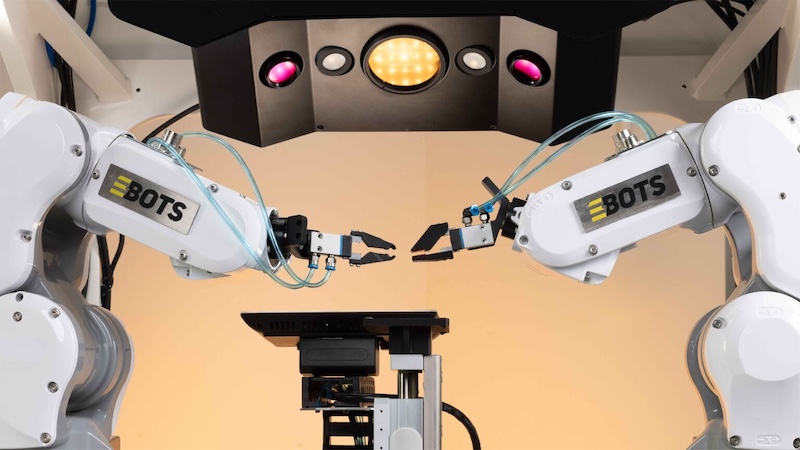

Instead of traditional single-task industrial arms, the company is building adaptive, AI-driven systems capable of human-like dexterity, rapid reconfiguration and dual-arm coordination – capabilities long considered difficult to automate.

Its pitch is straightforward: if reshoring is to work, manufacturers must be able to automate the kinds of delicate, variable and reformable-material tasks that have historically required human workers.

Xu brings a global perspective to this challenge. Before founding Ebots, he spent years observing how factories in Asia and Europe embraced automation not just to cut costs but to build more resilient production systems.

He argues that the US can only close its skilled-labour gap by taking a similar approach – treating automation as a strategic tool, not an isolated add-on.

As policymakers, investors and manufacturers debate how to rebuild America’s industrial capacity, Ebots is entering the market with the claim that intelligent, modular automation can give even small and mid-sized factories the flexibility they need to compete.

In this Q&A, Xu discusses why he believes the timing is right, what gaps in the market Ebots intends to fill, and how AI is reshaping the division of labour on the factory floor.

Interview with Zheng Xu

Robotics & Automation News: You’ve launched Ebots at a moment when reshoring and industrial revitalization are high on the US agenda. What specific manufacturing challenges or inefficiencies convinced you that this was the right time to start the company?

Zheng Xu: Several critical factors converged to make this the perfect moment. First, precision manufacturing faces an unprecedented workforce crisis – 40 percent annual turnover, months-long training cycles, and younger generations avoiding manufacturing careers. Facilities rarely operate at full capacity due to these staffing challenges.

Second, despite the risks presented by offshore manufacturing, US labor costs of $75,000+ per workstation make legacy human-dependent manufacturing economically unfeasible.

Third, legacy automation hasn’t solved the problem. Most robots have single arms, follow one program, and can’t perform precision work requiring fine motor skills.

They’re also incapable of handling reformable components like cables, leaving manufacturers stuck choosing between expensive human labor and inflexible automation.

Ebots addresses all three challenges by combining human-like dexterity with machine-level precision, delivering 99.95+ percent yield rates while operating 24/7. The market timing couldn’t be better for next-generation adaptive robotics.

R&AN: Many reshoring efforts struggle because of labor shortages and cost pressures. How does Ebots’ AI-powered robotics platform make it economically feasible to bring precision manufacturing back to the US?

ZX: Ebots fundamentally changes the economic equation for US manufacturing. We eliminate $150,000+ annual costs per workstation in salary alone, not to mention the training, sick days, and vacation time humans require.

Additionally, Ebots completely eradicates the 40 percent turnover rate and weeks-long reconfiguration cycles that plague the industry.

Our platform delivers 22μm accuracy achieving 99.95+ percent yield rates, virtually eliminating material waste and quality failures. We operate at twice the speed of human workers while running 24/7 without breaks, dramatically increasing output without expanding workforce or footprint.

Critically, we deliver complete ROI payback within months despite a 10-year operational lifespan. Our 15-minute reconfiguration time – versus weeks for legacy robots – enables rapid response to market demands without massive retraining costs.

This means US facilities achieve superior quality and faster time-to-market compared to offshore operations. Our synchronized dual-arm coordination even handles reformable components like cables, making all types of precision work economically viable for reshoring.

R&AN: You’ve described Ebots’ systems as “intelligent and modular”. Can you explain what sets your approach apart from traditional single-task automation, and how adaptability plays into your customers’ operations?

ZX: Legacy robots are single-purpose machines programmed for one specific task, requiring hours or weeks of reprogramming for changes.

Ebots is a self-learning platform combining 3D computer vision, cognitive processing, and synchronized dual-arm coordination to execute complex assembly processes across any product configuration.

Our adaptive AI continuously learns new tasks through advanced visual processing and precision movement coordination, and can switch tasks in just 15 minutes.

This means our systems can run one task during day shift and a different task at night – enabling manufacturers to handle twice the product variety with half the footprint.

Our dual-arm coordination handles reformable components like cables and wire harnesses – tasks impossible for standard single-armed robots.

Operating at 409 frames per second, we execute everything from delicate smartphone components to data center server assemblies with exceptional precision.

Customers aren’t buying a robot – they’re investing in a platform that creates manufacturing capabilities beyond human potential.

R&AN: How are lessons from Asia and Europe – where automation is more mature – shaping your technology roadmap or deployment model in the US?

ZX: Mature automation markets in Asia and Europe taught us that reliability and proven performance are non-negotiable. Manufacturers demand demonstrable results, which is why we focus on delivering 99.95+ percent yield rates in real factory environments before expanding capabilities.

We’ve learned to expand robot capabilities methodically – one step at a time – to ensure that each solution is rock-solid reliable. This builds trust with manufacturers who’ve seen prior automation projects fail because due to overpromises by the vendor.

The facilities achieving the greatest success view automation as strategic transformation, not just cost reduction. This shapes our entire approach.

Ebots isn’t merely a robotics vendor; we’re a partner in our customers’ business transformation efforts. Reliability in real factories comes first, then systematic capability expansion.

R&AN: Smaller and mid-sized manufacturers often face barriers to adopting advanced robotics. What design or business decisions have you made at Ebots to make automation accessible to that segment of the market?

ZX: We’ve made deliberate decisions to address SMB barriers. The biggest isn’t just cost – it’s inflexibility that makes legacy automation economically unfeasible for high-mix, low-volume scenarios.

Ebots excels precisely where legacy automation fails. By combining AI with industrial robotics and leveraging large language models, our systems master new tasks quickly without extensive programming.

SMBs don’t require millions of units to justify automation – some of their most profitable contracts are smaller batches of diverse products.

Neither the human workforce nor legacy automation can effectively serve this need. And our 15-minute reconfiguration time is transformative, enabling manufacturers maintain the agility that’s often their competitive advantage.

Finally, a rapid payback period – typically within months despite the cell’s 10-year lifespan – makes the business case accessible even with tighter capital constraints.

Our systems work alongside skilled human workers, enabling incremental adoption starting with high-value processes and expanding as results prove themselves.

R&AN: As AI reshapes the factory floor, how do you see the role of human workers evolving? Are we moving toward a workforce made up more of engineers and technicians than traditional machine operators?

ZX: Absolutely. We’re not eliminating jobs – we’re fundamentally upgrading the nature of manufacturing work.

Repetitive, labor-intensive tasks with 40 percent turnover rates are being automated, creating demand for higher-skilled, better-compensated positions: maintenance technicians, machine learning engineers, and design engineers who optimize performance and develop new applications.

Ebots is designed to work alongside skilled human workers, not replace them entirely. Our dual-arm systems handle repetitive precision work, freeing the organization’s most skilled workers for innovation, process improvement, and problem-solving.

The best assemblers can never truly be replicated – but Ebots elevates the entire workforce by removing manual assembly bottlenecks.

Our rapid learning and 15-minute reconfiguration time enable facilities to expand product portfolios dramatically, creating more diverse, interesting work for humans.

The vision is seamless human-AI collaboration – humans directing strategy and innovation while Ebots delivers consistency, precision, and tireless execution that modern manufacturing demands.

R&AN: Looking ahead, what is your long-term vision for Ebots? Do you see it primarily as an automation provider, an AI platform for manufacturing intelligence, or something larger in the industrial ecosystem?

ZX: Our vision is transforming how goods are manufactured globally. While we deliver immediate value as next-generation robotic automation, we’re building toward a cognitive manufacturing ecosystem that fundamentally reimagines factory operations.

Imagine a factory where a chief AI system reads manufacturing specifications, intelligently divides processes into discrete steps, and dynamically assigns tasks to individual AI-powered robots.

Each specialized robot executes assignments while providing continuous feedback about performance, improvements, and optimizations.

This creates a self-optimizing, adaptive manufacturing environment that continuously learns and improves at impossible human scale and speed.

Near-term, we’re proving our core value: human-like dexterity with superhuman precision solving critical workforce shortages.

But our larger vision positions Ebots as the foundational intelligence layer for next-generation manufacturing – building cognitive infrastructure that enables factories to operate as interconnected, intelligent systems delivering unprecedented agility, consistency, and cost-efficiency across any product configuration.