Manufacturing floors never sleep. Machines keep running, shifts rotate, and information has to keep moving. Yet internal communication often depends on fragile systems, such as walkie-talkies, paper logs, whiteboards, and supervisors overloaded with responsibility.

The result is familiar to most plant managers. Delays. Confusion. Missed messages. Costly mistakes. In fact, poor communication is an invisible budget drain, which costs large companies an average of $62.4 million per year and mid-sized firms about $420,000 per 1,000 employees.

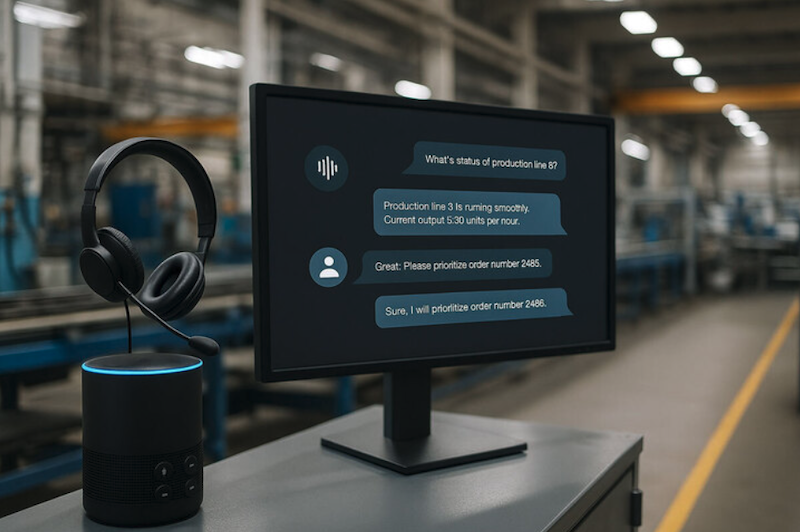

Voice AI is silently revolutionizing the way factories talk to themselves. Instead of fragmented tools, manufacturers are starting to apply always-on voice systems that listen, respond, and route information in real time.

When built upon fast, low-latency infrastructures, such as Falcon voice API for businesses, these systems become reliable enough to run critical internal workflows without slowing down production.

Here are five practical ways in which voice AI is already reshaping communication on the manufacturing floor, without adding complexity and disrupting existing teams.

1. Real-Time Shift Handover, Without Human Bottlenecks

Shift changes are among the most vulnerable moments in any manufacturing operation. Important details often live in handwritten notes or rushed face-to-face updates. That leaves gaps.

Voice AI solves this with spoken, structured shift handovers. Operators can speak naturally to a system that captures machine status, maintenance notes, output targets, and safety concerns. That way, the incoming teams simply have to listen to clear voice summaries, not decipher messy logs.

This is done to create continuity without relying on perfect human memories. It also reduces repeated questions and guesswork during critical startup periods.

2. Automated Task Routing Between Teams

The manufacturing floor is a complex ecosystem. Maintenance, quality, logistics, and production teams are mutually dependent on each other. Traditionally, the coordination among teams is done through manual mechanisms that are slow.

Automation is brought into this flow by means of voice AI. In case of a fault of the machine, a spoken request routes a task to maintenance; when material stock runs low, logistics gets a real-time voice alert; if there’s a quality issue, the supervisors are informed on the spot, not an hour later.

This reduces idle time and eliminates the need for continuous phone calls or physical walk-arounds. It also reduces decision fatigue: workers spend less time figuring out who to contact and more time fixing problems.

3. Instant Safety Alerts That Reach the Right People

Safety communication usually relies on sirens, flashing lights, or supervisors physically moving through the floor. That works, but it is imprecise and doesn’t scale well.

Voice AI means alerts become pinpointed and timely. A fault or unsafe condition detected can trigger a spoken instruction sent to relevant zones or individuals. Workers hear clear directions in real time, rather than vague alarms.

This matters in high-risk environments where every second counts and clarity saves lives.

Key Improvements Include:

- Spoken instructions for evacuation or shutdown

- Automated hazard updates if sensors detect anomalies.

- Location-specific warnings instead of plant-wide panic

The factory becomes safer, not because people work harder, but because communication becomes smarter.

4. Hands-Free Reporting for Workers on the Line

Operators cannot always stop to type, write, or tap screens. Physical interfaces are inconvenient because of gloves, noise, or safety protocols.

Voice AI makes the reporting activity a natural one; one can almost immediately utter:

- Production counts

- Downtime reasons

- Quality observations

- Equipment anomalies

The system captures this information and updates central systems automatically. No paper. No delays. No manual data entry.

It improves data accuracy and provides real-time visibility to managers without pulling people away from their stations. The advantage is immediate, especially when considering that up to 48% of employees report receiving unclear instructions, which is a primary driver of errors and lost productivity.

5. Always-On Knowledge Access for Faster Decisions

The training documents and standard operating procedures often live in binders or terminals far from the workspace. No one has time to hunt for a manual during a live issue.

Voice AI transforms the knowledge base into something instantly requestable by workers.

For instance, a technician can ask how to reset a sensor. A new worker may ask for step-by-step instructions. A supervisor can request simple spoken queries about machine history.

The result is faster decisions and fewer disruptions.

This is where low latency makes all the difference. If the response is slow or awkward, people stop using the system. When responses are instant and natural, adoption becomes automatic.

Conclusion: What Does This Mean for Today’s Manufacturing?

Factories are no longer isolated mechanical spaces, but rather have become data-driven, sensor-rich, and increasingly automated. Communication must be similarly upgraded.

Voice AI does not replace any workers. It’s all about eliminating friction in the way information flows. When people are not required to chase updates, walk long distances for answers, or pause work to type reports, productivity rises naturally.

Mistakes fall, safety improves, and stress decreases.