By Kelly deVos, communications specialist, Ira A. Fulton Schools of Engineering

They run beneath our feet, unseen but essential. Millions of miles of pipeline carry the natural gas, crude oil and refined fuels that keep modern life running. Yet as this buried infrastructure ages, cracks, leaks and ruptures are becoming alarmingly common.

From 2002 to 2021, pipeline incidents in the US caused 276 deaths, more than 1,100 injuries and $10 billion in damage. With roughly 650 serious incidents each year, the need for safer, smarter pipeline inspection technology has never been clearer.

Despite the risks, many pipelines go years without a thorough inspection. Some can’t be inspected at all. Known as unpiggable pipelines, these sections twist through narrow turns, outdated valves and complex connections that standard inspection tools simply can’t navigate. The result is a costly blind spot for one of the nation’s most critical systems.

Arizona State University researchers are working to change that. Supported by the US National Science Foundation, their project is creating a new generation of innovative robotic systems and artificial intelligence, or AI, models designed to make pipeline inspection faster, safer and more reliable than ever before.

Soft robotics for a hard problem

Leading the effort is Wenlong Zhang, an associate professor of manufacturing engineering in the School of Manufacturing Systems and Networks, part of the Ira A. Fulton Schools of Engineering at ASU. As principal investigator, Zhang oversees the project’s development and leads the creation of a new class of soft, flexible inspection robots capable of navigating pipes that traditional tools can’t reach.

“Pipelines can be inspected using in-line tools with magnetic flux leakage and ultrasonic waves,” Zhang says. “However, due to the complex geometries of pipelines, over- or undersized valves, small-radius bends and other challenges, many critical segments of the 2.6 million miles of pipeline in the US are uninspected.”

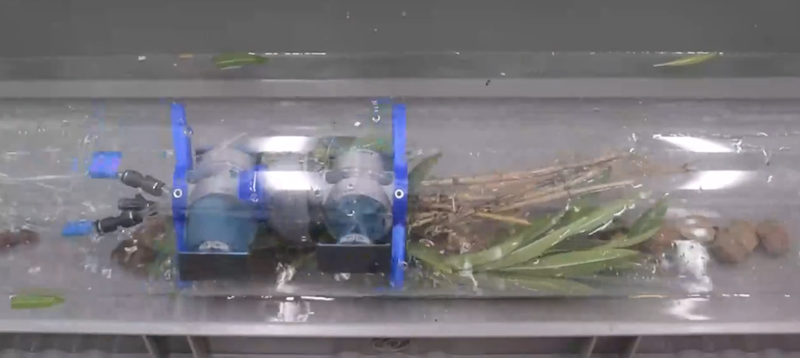

His team’s solution is an autonomous, soft robot inspired by inchworms, composed of inflatable fabric actuators allowing it to grip, stretch and move through narrow, twisting pipes. The robot can carry lightweight sensors to detect cracks and corrosion while adapting its body to the pipeline’s shape.

“This project will allow us to significantly improve the efficiency, endurance and autonomy level of future in-pipe robots,” Zhang says.

But the impact goes beyond robotics. Zhang sees the technology as a model for how intelligent robotics can transform aging infrastructure.

Forecasting failure to prevent disaster

While Zhang’s robots collect data, Yongming Liu, a professor of mechanical and aerospace engineering in the School for Engineering of Matter, Transport and Energy, part of the Fulton Schools, is working to predict what that data means. His focus is on understanding how pipelines fail in real-world conditions and anticipating problems before they occur.

By blending theory and machine learning, Liu’s team is creating a predictive framework that helps utilities see problems coming long before they become dangerous. His models can estimate a pipeline’s remaining lifespan under complex conditions pipelines face daily – where pressure, corrosion and environmental factors constantly fluctuate – to offer a smarter, more proactive approach to maintenance and safety.

“Energy infrastructure safety is fundamental to both the economy and public well-being,” Liu says. “Many of these systems are aging, and understanding how to extend their lives safely is a grand scientific and societal challenge.”

AI tools helping stakeholders see the full picture

At the heart of the project’s data intelligence is Hao Yan, an associate professor of industrial engineering in the School of Computing and Augmented Intelligence, part of the Fulton Schools. Yan and his team are developing a new kind of AI that doesn’t just predict when something might go wrong. It also explains why.

The team’s system fuses information from multiple sources, including real-time sensor data from inside the pipes, detailed physics simulations and decades of written accident reports. By integrating all of these perspectives, the AI can identify subtle patterns and emerging risks that would be invisible to any single data source.

Unlike traditional black box algorithms, Yan’s framework emphasizes transparency and trust. It not only makes predictions but also measures how confident it is in those predictions, grounding each decision in physics and engineering knowledge. The result is an intelligent system that engineers can interpret, regulators can trust and operators can use to act before small problems become major failures.

Ultimately, Yan envisions a future where utility operators receive early, data-driven warnings before a failure occurs.

“By teaching AI to read and learn from decades of pipeline accident reports, we can uncover recurring human, environmental and mechanical risk factors that traditional models overlook,” Yan says. “These insights can give utilities early warnings about potential failures, protecting people’s safety and minimizing costly service disruptions.”

Turning research into real-world practice

To ensure the project’s technologies make sense in the real world, Hanna Breetz, an associate professor in ASU’s School of Sustainability, is leading the project’s stakeholder engagement and policy analysis. Her work bridges the gap between engineering innovation and the complex regulatory and political environment surrounding energy infrastructure.

Breetz’s team is interviewing policymakers, industry leaders and public interest groups to identify emerging safety codes and monitoring standards. Their insights will guide how the engineering team designs technology that meets regulatory needs while being practical to adopt. As the project progresses, Breetz will also help translate its findings into publications and outreach materials for industry and government leaders.

A safer future, powered by smart engineering

What makes this project especially distinctive is its interdisciplinary nature. Zhang, Liu, Yan and Breetz are blending expertise from robotics, materials science, AI and policy studies – disciplines that rarely meet but are all essential for reimagining infrastructure management.

The team is also working with collaborators at Michigan State University and GTI Energy, an energy transition technology company, which will host field demonstrations at its Illinois test site. There, the robots and AI systems will be tested under realistic conditions and industry experts will provide feedback to refine the tools before real-world deployment.

The researchers hope their work will pave the way for a new generation of intelligent infrastructure systems, ones that can monitor themselves, predict problems early and help engineers make data-informed maintenance decisions.

As Liu puts it, “This project will demonstrate that proactive, data-informed safety management is possible on a national scale.”

And while the technologies emerging from this highly interdisciplinary collaboration may one day protect the pipelines beneath our feet, their true impact could reach even further by transforming how we use robotics and AI to care for the infrastructure that sustains modern life.

This story was originally published on the ASU website, and is republished here.