Industrial automation and robotics are becoming increasingly dependent on materials that can withstand demanding thermal and mechanical environments.

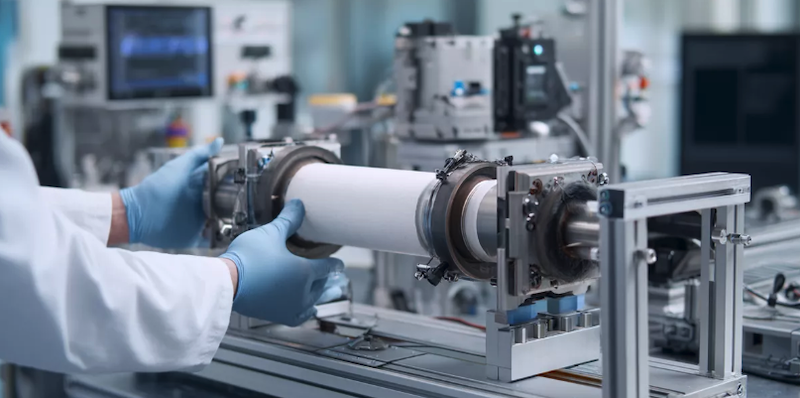

To support this shift, ADCERAX has introduced a new generation of high-purity alumina ceramic tube technology engineered for high-temperature control, insulation, and structural stability in next-generation automated systems.

As robots move into more extreme operating conditions – industrial furnaces, precision thermal modules, semiconductor handling, and chemical processing – materials must ensure reliability at temperatures above 1500°C while maintaining dimensional precision.

ADCERAX’s latest alumina tube platform is designed to meet these requirements, offering controlled microstructure, strong dielectric insulation, and long-term resistance to thermal cycling.

Engineered from high-purity Al₂O₃, the new tubes demonstrate low thermal expansion, excellent creep resistance, and minimal deformation under sustained heat loads.

This makes them suitable for heating assemblies, tube-based sensors, furnace rails, and compact robotic mechanisms where both insulation and structural rigidity are critical.

Across sectors such as automated manufacturing, environmental systems, semiconductor processing, and scientific instrumentation, the need for stable high-temperature components continues to rise.

The broader field of industrial alumina ceramics is playing a growing role in enabling robotics deployments that require precise thermal control and long service lifetimes.

Industry analysts note that as automation becomes more integrated with AI-driven process control, the role of engineered ceramic components will expand.

High-temperature materials are now considered foundational to robotics operating in harsh environments, particularly in energy, advanced manufacturing, and high-throughput laboratory automation.

Commenting on the launch, an ADCERAX engineering representative said: “Today’s automation systems require materials that remain stable under continuous thermal load while delivering mechanical reliability.

“Our new alumina tube line is specifically developed to meet these demands in robotics, sensors, and industrial heating applications.”

The new product line is manufactured with tight tolerances and supports custom geometries for integration into specialized equipment platforms. This ensures compatibility with OEM design requirements across multiple automation segments.

ADCERAX is a global supplier of engineered ceramic components used in high-temperature and high-precision environments.

With a product portfolio covering alumina, zirconia, silicon nitride, and silicon carbide, the company provides custom machining, engineering collaboration, and technical material solutions for industrial clients worldwide.

More information is available at ADCERAX.