AGRITECHNICA 2025 spotlights innovative technologies for agriculture. At the trade fair, HORSCH will present a groundbreaking application in precision farming.

The new spot spraying solution uses the AI functionality of TTControl’s FusionAI computing platform. HORSCH’s first pilot projects with FusionAI are being deployed successfully since early 2025.

Precision farming uses data collected via sensors, GPS, or drones as a basis for cultivating fields more resource-efficiently with the help of artificial intelligence (AI).

The goal is to increase yields while reducing environmental impact and saving costs. AI applications are an important factor in modern agriculture, but their development is complex and requires expertise from a wide range of domains.

HORSCH is a German agricultural machinery manufacturer that also works on solutions for precision farming. It developed a spot spraying application that uses cameras and AI to detect individual weeds in the field and enables the targeted use of herbicides.

This “green in brown” system will be presented at AGRITECHNICA 2025 and is being further developed in collaboration with TTControl.

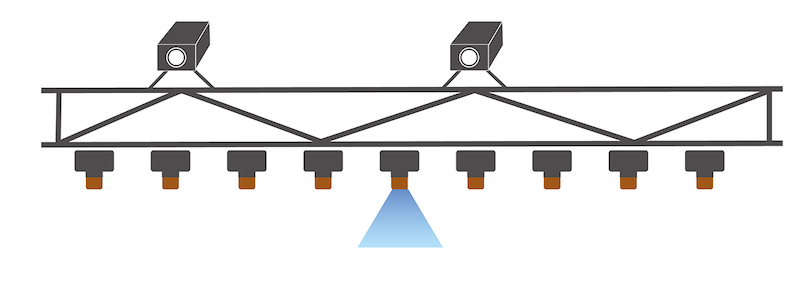

Spot spraying is a precision farming application that uses optical sensors and object recognition in combination with artificial intelligence (AI) to detect weeds in fields, thereby reducing the use of herbicides.

Caspar Ruß, PU Crop Care – Electronics, at HORSCH, says: “We are working with FusionAI to further develop our spot spraying solution.

“It has all the relevant interfaces for challenging field use – from 100/1000BaseT1, GSML2, with high bandwidths to the classic CAN bus. It also has sufficient computing power to accurately detect plants even at high driving speeds.

“FusionAI opens up new technical possibilities for reading a wide range of sensor data and thus serves as a key technology that enables us to implement AI-supported plant detection and adaptive application strategies.”

The first pilot applications of the new spot spraying solution with FusionAI in crop protection equipment have been in use since the beginning of the year and provide the basis for continuous further development and improvements to HORSCH’s system.

TTControl’s intelligent computing platform FusionAI has been specially developed for the harsh environmental conditions found in mobile machines and offers a future-proof solution for implementing intelligent, safe, and efficient, highly automated machine functions.

The modular architecture separates the computing unit and display functionality, offering maximum flexibility in system design. The AI accelerator enables AI-supported image processing and environmental perception.

Thanks to numerous interfaces – including multiple CAN, Ethernet, USB, and camera connection, as well as compliance with functional safety and cybersecurity standards, FusionAI is ideally suited for future-oriented automation, safety, and telematics solutions.

Christiana Seethaler, vice president of product development at TTControl, says: “The collaboration with HORSCH is very exciting and informative for us, as FusionAI enables us to support the realization of the new generation of smart, software-defined agricultural machinery.

“FusionAI is a powerful, highly versatile computing platform: it can, for example, be used as a central computing platform in the machine, for AI applications, as a display controller, or, in combination with the connectivity module, as a telematics unit.

“In addition, FusionAI supports various security functions such as secure display or touch input and already meets the requirements of the Cyber Resilience Act.”

Main image: HORSCH’s spot spraying solution uses the AI-functionality of TTControl’s FusionAI to recognize weeds with cameras and AI and enable a targeted use of herbicides. © HORSCH