In today’s era of Industry 4.0, efficient and precise labeling solutions are crucial for the smooth operation of smart factories. They enhance traceability, quality control, and support automation and digitalization across all manufacturing processes.

Proper labeling ensures that each component and finished product can be accurately tracked from production to delivery, reducing errors, improving inventory management, and boosting overall efficiency.

The following explores 10 innovative labeling solutions that optimize operations in smart factory environments and help companies remain competitive.

Automated Label Printing Systems

Automated label printing systems serve as the backbone of modern manufacturing. They allow rapid, error-free production of labels in large volumes. Integrated directly into production lines, these systems can print and apply labels in real time, reducing downtime and minimizing manual labor.

Automated printing also includes verification mechanisms, preventing mislabeling and ensuring critical information is applied correctly every time. This level of precision ensures consistency across all products.

RFID-Enabled Labeling

Radio Frequency Identification (RFID) technology has transformed asset tracking within smart factories. By attaching RFID tags to machinery, components, or finished products, companies gain real-time visibility into inventory and production flow.

This facilitates precise stock management and helps identify issues before they affect schedules. RFID labeling also supports predictive maintenance, allowing teams to plan interventions before breakdowns, avoiding costly downtime and supporting continuous operational reliability.

Barcode Integration

Barcodes remain a reliable method for product identification and tracking. Integrating barcode systems into production lines allows each item to be scanned quickly, with data automatically logged into central systems. This reduces human error and enhances traceability.

Barcodes can be customized for serial numbers, batch codes, and expiration dates, ensuring accurate information is available for quality assurance and enabling rapid workflow analysis. They also support seamless communication between different departments in real time.

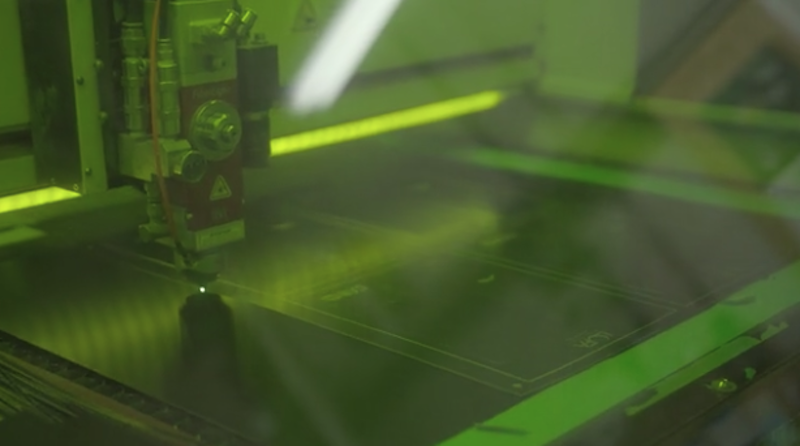

Durable Thermal Transfer Labels

Thermal transfer printers provide high-quality, long-lasting labels suitable for harsh manufacturing conditions. These labels withstand high temperatures, chemicals, and abrasion, maintaining legibility throughout a product’s lifespan.

Thermal transfer technology helps factories uphold labeling standards even in demanding environments, supporting compliance and reliability. In industries like automotive or heavy machinery, durable labels ensure critical information remains visible despite extreme conditions and frequent handling.

Digital Nameplates with NFC Technology

Digital nameplates with Near Field Communication (NFC) offer wireless access to critical product or machinery information. A simple scan with a mobile device can reveal specifications, service histories, or operational instructions. This reduces downtime and streamlines troubleshooting while improving equipment management.

Digital nameplates also support dynamic data updates, allowing information to be refreshed instantly without replacing physical labels, which is particularly useful in highly automated production settings.

Cloud-Based Label Management

Cloud-based label management systems allow centralized control of labeling across multiple locations. Templates, updates, and print jobs can be managed remotely in real time, offering flexibility and scalability.

This ensures consistent labeling standards, reduces administrative overhead, and allows quick adjustments for production changes or regulatory requirements. Cloud systems also support analytics, providing insight into printing efficiency and potential workflow bottlenecks, helping managers make data-driven operational decisions.

Direct Thermal Printers for Variable Data

Direct thermal printers are effective for printing labels with variable data like serial numbers, batch codes, or production dates. Their speed and precision make them ideal for high-volume manufacturing, where each product must be uniquely identified.

Integrating these printers into production workflows ensures accurate documentation without slowing the assembly line and reduces interruptions caused by jams or misfeeds, keeping production both fast and reliable.

QR Code Labels for Enhanced Information Access

QR codes allow employees to access additional product information instantly. Scanning a code can reveal manuals, instructional videos, or maintenance records, improving efficiency, worker training, and safety.

QR codes also enable traceability across the supply chain, allowing partners to access verified product data without exposing sensitive internal systems. This digital approach enhances communication between production teams and maintenance staff.

Industrial Labeling Stations

Industrial labeling stations are designed for precision and repeatability in manufacturing environments. They can apply labels consistently to various products or packaging types, even at high speeds. Automating labeling helps factories maintain standard output, reduce errors, and ensure compliance.

Many stations include vision systems to verify label placement, further reducing mistakes and maintaining product consistency while supporting quality assurance initiatives across production lines.

Sensor-Embedded Labels

Labels with sensors monitor conditions like temperature, humidity, or shock exposure. They transmit data in real time to centralized systems, enabling proactive monitoring and quality assurance. This is particularly useful for sensitive equipment or perishable goods, ensuring deviations from optimal conditions are immediately detected.

Even traditional solutions like a machine nameplate remain essential, providing vital specifications, certifications, and maintenance guidance for safe and efficient operations in any smart factory.

Implementing these labeling technologies allows smart factories to achieve higher levels of automation, accuracy, and traceability.

They enhance production visibility, reduce errors, and streamline maintenance processes while supporting data-driven decision-making at every stage of manufacturing, helping companies remain agile and competitive in today’s dynamic industrial landscape.