Yamaha Motor has released the Yamaha Motor Cobot, a new seven-axis collaborative robot designed to operate safely alongside humans. The company has also introduced a compact, dedicated controller developed specifically for the new model.

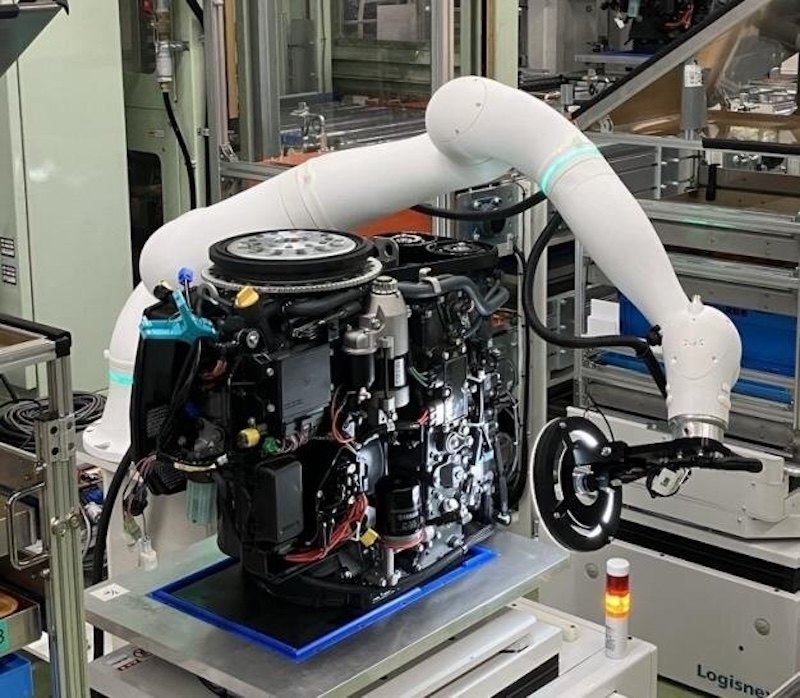

The Yamaha Motor Cobot marks the company’s first commercially available collaborative robot and employs a seven-axis configuration that provides a degree of freedom similar to a human arm.

According to Yamaha, the additional axis enables “delicate movements, such as reaching into confined spaces that cannot be accessed by 6-axis robots or approaching targets by moving around obstacles”.

Each axis incorporates an integrated torque sensor that allows compliance control for smooth, fluid motion. The robot can detect and stop immediately upon contact with workers. Yamaha says it is “on track to receive functional safety certification from TÜV SÜD”, the independent testing and certification body.

The cobot can operate in two speed modes – a reduced-speed collaborative mode for work near humans and a high-speed mode for use in cordoned-off areas.

It has a maximum reach of 1,300 mm and a rated payload capacity of 10 kg, with a maximum speed of 3,000 mm/s in high-speed mode. Repeatability is ±0.04 mm in accordance with ISO9283 standards.

Weighing 45 kg, the robot arm can be floor-mounted and uses AC servo motors with a hollow-shaft design. Torque sensors are integrated on all seven axes, while position detection relies on absolute magnetic and optical encoders.

The unit can handle wrist moments of up to 28 N·m for twist and pitch and 12 N·m for roll, with corresponding allowable inertias of 0.95 kg·m² and 0.25 kg·m² respectively.

Yamaha has also introduced a dedicated controller for the cobot, measuring 337 mm (W) × 309 mm (D) × 122 mm (H) and weighing 7 kg. The controller operates on a 48V DC power supply – within a range of 47.0 to 50.0 V – and consumes 960 W for the main supply and 145 W for control.

The company notes that the DC48V input “allows battery sharing with Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), enabling operation of the Yamaha Motor Cobot while mounted on these platforms”.

The controller features a simple pendant interface and compact housing to reduce control-panel size, and supports both conventional text-based programming and visual “block programming”, which allows new users to assemble instruction blocks intuitively.

Yamaha says the cobot has already been introduced for evaluation at its Fukuroi South Factory, the company’s main outboard motor production site, where its “operation and functionality have been verified under actual production conditions”.

In addition to performance and safety, Yamaha has emphasized a “friendly-looking cobot design” with curved surfaces and a non-gloss finish to avoid the cold, industrial appearance of conventional robots.

With the launch of this model, Yamaha adds a collaborative robot to its existing automation portfolio, which includes single-axis robots, SCARA robots, and linear conveyor modules.