Toyota pilot program and Woven Capital investment support automotive manufacturing breakthrough

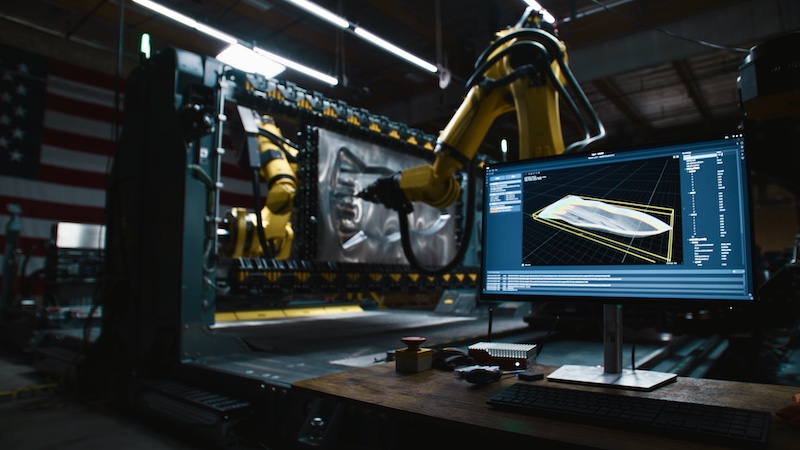

Machina Labs, a provider of advanced manufacturing and robotics systems, has unveiled its next-generation manufacturing methods for automotive body panels and accessories.

This will enable automakers to bring customized vehicles to market at mass-production prices, representing a breakthrough in automotive manufacturing customization.

The launch took place at UP.Summit, alongside a pilot of the technology with Toyota Motor North America and a strategic investment from Woven Capital, Toyota’s growth-stage venture investment arm.

The pilot project will apply Machina’s RoboForming technology to customize production body panels, with the goal of bringing automotive-grade quality and throughput to low-volume manufacturing.

This capability directly addresses a massive and growing market: the automotive customization and accessories industry, valued at $2.4 billion in 2024 for trucks alone.

Conventional high-volume manufacturing often overlooks opportunities for customized production. By introducing flexible, low-volume production capabilities within existing operations, Machina Labs is unlocking new value streams at scale.

Ed Mehr, co-founder and CEO of Machina Labs, says: “Traditional production tools are often massive, comparable in size to a small car and weighing over 20 tons.

“With our solution, the need for dedicated tooling per model variation is eliminated. That means lower project capital, less storage both in-plant and for past models, which today can last up to 15 years, and faster production changeovers.”

Zach Choate, general manager of production engineering and core engineering manufacturing at Toyota Motor North America, says: “We envision a future where customization is available for every Toyota driver. The ability to deliver a bespoke product into the hands of our customers is the type of innovation we are excited about.”

George Kellerman, founding managing director at Woven Capital, says: “AI-powered manufacturing is transforming how products are designed and produced at scale.

“Customers increasingly demand more personalized products while engineers need faster, more cost-effective paths from concept to production without the constraints of traditional supply chains.

“We’re excited to team up with Machina Labs, supercharge their development roadmap in automotive, and support their journey in accelerating innovations that advance the future of manufacturing.”

Machina Labs’ AI driven RoboCraftsman platform and RoboForming technology is a proprietary form of incremental sheet forming and has a proven ability to deliver highly customized panels from sheet metal for automotive and aerospace vehicles at high volume, high quality, and short lead time, a capability which is not otherwise possible in today’s manufacturing processes.

Furthermore, this shift impacts process flow within the factory: current manufacturing models require separate storage, repackaging, and dedicated assembly lanes for custom parts.

Machina’s approach enables on-demand part production in low volumes from cells near the assembly line, allowing for dynamic batching or broadcast-driven manufacturing – all without disrupting existing flow.