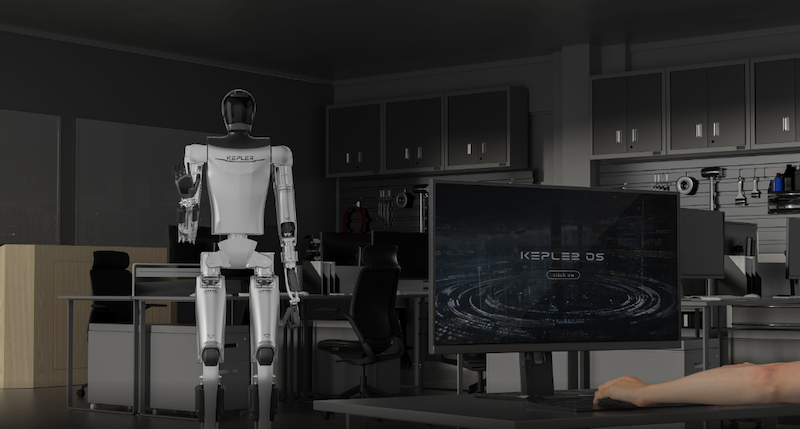

Shanghai-based Kepler Robotics has started mass production for its humanoid robot, the K2 “Bumblebee”, which the company describes as the world’s first commercially available humanoid built on a hybrid architecture.

The move signals a shift from research prototypes to large-scale deployment and is being billed as a milestone for the global humanoid robotics industry.

Kepler said it has already signed framework agreements covering several thousand units, with a total contract value in the hundreds of millions of yuan.

What hybrid architecture means

In this context, “hybrid architecture” does not refer to building design but to the robot’s mechanical and computational structure.

The K2 combines different types of actuators – roller screw linear actuators and rotary actuators – to achieve more natural, stable movements with longer operating life.

On the computing side, the hybrid approach blends onboard processing with cloud-based resources, allowing the robot to run tasks locally while tapping into remote servers for heavier workloads such as training and simulation.

Kepler said the system achieves up to 81.3 percent energy efficiency, allowing the robot to operate for up to eight hours on a single charge.

The machine also uses reinforcement learning and imitation learning to replicate human-like walking, including heel strikes and toe-off motion.

Industrial applications

The K2 is designed for industrial integration, with a dual-arm payload capacity of 30 kg, enabling it to handle carrying, loading, and unloading tasks.

It can navigate factory floors and logistics centers, execute assembly work, and even be deployed in public demonstrations or specialized operations.

A semantic task-processing system allows it to follow natural language commands for functions such as sorting or guided tours.

Priced at RMB 248,000 (around $34,000), the K2 undercuts the million-yuan prototypes that have dominated the field, lowering the cost of adoption for businesses.

Building an ecosystem

Kepler said its rollout marks the beginning of what it calls the “first year of mass production” for humanoid robots.

The company is working with supply chain partners and strategic investors to scale manufacturing and create a broader humanoid robotics ecosystem. Investors include Tao Motor, Friend, Hanwei, and others.

According to Kepler, humanoids such as the K2 Bumblebee can take on repetitive tasks in manufacturing or high-risk operations in specialized fields, improving both productivity and safety.