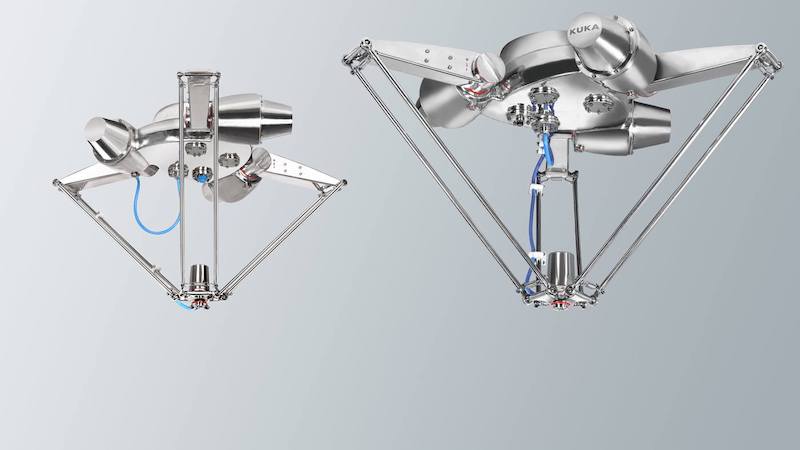

Kuka Robotics has launched a new delta robot for which “hygiene is of the essence”, according to the company.

Kuka says the new robot is made entirely of stainless steel and calls it “the hygiene robot”, adding that it “impressively performs challenging pick-and-place applications in the food and packaging industries”.

It also scores highly in the electronics and pharmaceutical industries with flexible application possibilities.

Kuka says this new delta robot is “the first of its kind” at the long-established robot maker, adding that it “offers outstanding performance at a great price”.

This robot type of the low payload category will be the latest member of the Kuka product family from April 2021.

With its parallel kinematic system and small footprint, the KR Delta robot is particularly suitable for precise pick-and-place tasks.

Thanks to its stainless steel body, it is ideally suited to operation in hygienically sensitive areas, such as in direct contact with food or medicines.

Furthermore, the KR Delta robot is designed to require minimal maintenance: the gear unit is encapsulated and the ball joints are made of a self-lubricating material.

The parallel arm robot can be installed on the ceiling and stands out with a high degree of accuracy and a cycle time of 0.5 seconds (in the small Adept cycle) with a payload of 1 kilogram.

With a reach of 1200 millimeters and a payload capacity of up to 6 kilograms, the KR Delta robot offers first-class results in sorting and packaging applications. It is also designed according to the principle of “hygienic design”.

Since its entire body is made of stainless steel, the KR Delta hygiene robot is temperature-resistant and corrosion-resistant.

With a protection rating of IP 67 for the entire robot and IP 69K for axis 4, it is easy to clean and disinfect – even using a high-pressure cleaner with a pressure of up to 100 kPA.

The advantage: the simplified processes help companies to reduce downtimes that are otherwise necessary for cleaning and maintenance.

At the same time, the new member of the Kuka portfolio meets the strictest requirements of the food industry. From its market launch, the KR Delta hygiene robot will be TÜV-certified for compliance with the requirements of the US Food and Drug Administration and the German Food and Feed Code.

The small robot is controlled by the KR C5 micro – the latest control technology from Kuka. To enable it to perform its tasks even more efficiently in terms of resources, the KR Delta can switch between different production scenarios, such as seasonal packaging variants.

It is particularly suitable for the consumer goods industry, especially for fast-moving consumer goods. For this, the hygiene robot uses the software package Kuka.PickControl with conveyor tracking and integrated image processing.

In combination with a camera and the Kuka.VisionTech software, which recognizes objects even in unstructured environments, even more flexible applications can be defined for the KR Delta robot. These range from sorting to loading of different objects.

Roland Ritter, product manager mechatronics, platform portfolio management, says: “Designed to resist: the new KR Delta robot from Kuka meets the strictest hygiene standards and its ease of cleaning reduces downtimes for companies.”