With good labor getting harder to find and retain, Midwest Engineered Systems has found that automating the more redundant production processes has become a necessity.

Automating these tasks allows the transfer of valuable labor resources to more important tasks.

MWES’s robotic case packing solution does just that for bagged products that have previously proven difficult to automate.

Of course there’s other drivers for bringing in automation, including seeing demand increase faster than humans could pack.

MWES custom designs, builds and services automation systems for its customers’ specialized needs.

The MWES case packing system allows most firms to run their production systems at speeds closer to what the upstream automation can theoretically achieve without worrying about bottlenecks downstream.

“With the labor market as tight as it is, it’s best to not waste human labor on repetitive practices when a machine can free your workforce to work on more high value operations.”

Says Pete Gratschmayr, VP of sales and marketing, MWES: “This thinking has been at the core of our design process for our case packer system.”

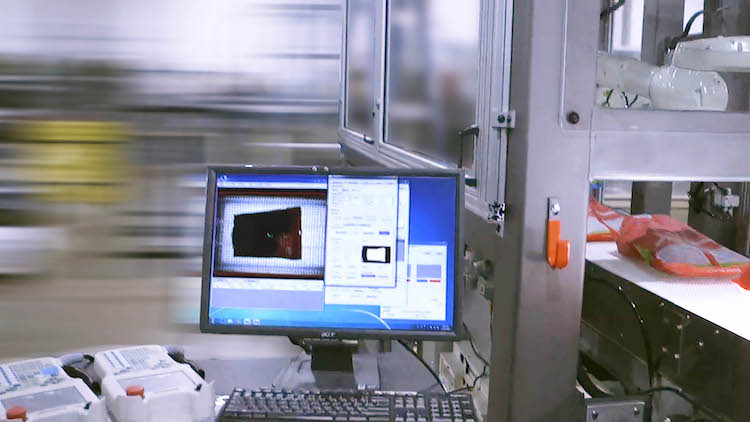

To achieve these benefits, the MWES case packer machine uses machine vision to locate products as they enter the machine and translates that information to the robotic picking arms.

The vision system not only conveys the location of the product but its orientation on the belt. This allows for far more precise placement into secondary packaging – a necessity for pack patterns that fill tight spaces.

The robots themselves use a proprietary vacuum end effector designed specifically for the rigors of picking and placing bagged products.

This system not only can be adjusted to handle more fragile materials, it’s also excellent at addressing the varying topology of the bags themselves.

These grippers help guarantee a near-zero drop rate even while running at the high pick place speeds the MWES machines can operate at.

Using its two robot configuration, the MWES case packing machine is able to pack up to 80 bags per minute with no drops.

To make installation easy, the entire case packing machine is encapsulated within its own welded steel frame.

Installation comes down to securing the machine in its location and connecting power, air and Ethernet connection and the system is ready to go.

In most instances, systems can be up and running in a day, making the MWES case packer as ‘turnkey’ as they come.

Further, its compact design makes for integrating into a production area easy. Movement and positioning can be done with just a forklift.

Depending on robot configuration, MWES’ systems could also be installed in some cold room environments.

For some of its customers, the compact footprint of the case packer has even opened up valuable floor space.

Gratschmayr says: “We’ve worked on the system to make it quick to install and easy to run. Right now it can be installed in less than a day and adding another product recipe takes about an hour for an operator.

“We think this really cuts down on the fear and uncertainty of adding this sort of automation.”

The performance of MWES case packing systems has allowed customers to relocate 2-3 workers a shift to more meaningful tasks while offering production lines to operate at a much faster pace.

In their place only partial supervision of the machine is needed. The system also opens the door to downstream automation including a palletizing system to take the secondary packaging ready for shipping, as well as upstream box erectors to further automate the process.

MWES now offers these case packing machines as a standardized system that allows for fairly quick order turnaround times.

The systems can also be ordered with three integrated robots, allowing for packing speed of up to 120 bags per minute.