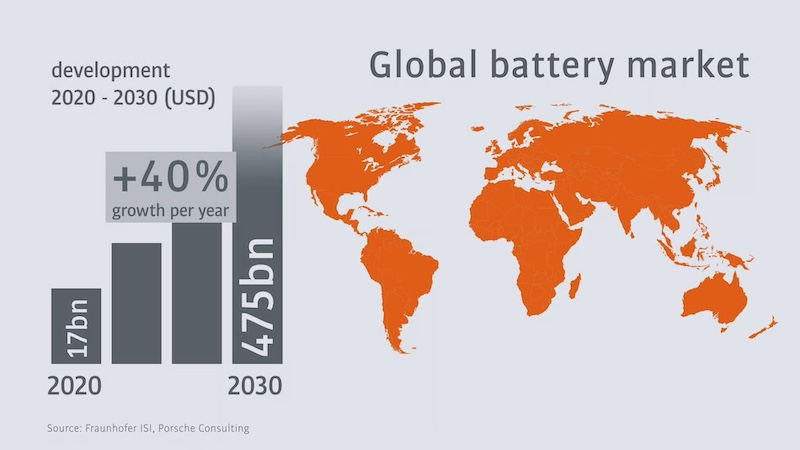

The global battery market is forecast to grow by around 40 percent annually through 2030, with US cell production alone expected to increase 28-fold by 2032.

For automation suppliers, the surge represents both a challenge and an opportunity: robots are emerging as critical tools in building the next generation of energy infrastructure.

Kuka, the Augsburg-based industrial robot maker, says automation is becoming essential for meeting demand at scale while maintaining quality and controlling costs.

Its systems are already being deployed in projects spanning cell assembly, battery pack production, and recycling.

At the Karlsruhe Institute of Technology in Germany, for example, Kuka robots are part of the AgiloBat project, which uses “mini-environments” to assemble cells.

These enclosures reduce the reliance on large, energy-hungry dry rooms while still ensuring precise environmental control.

In Nuremberg, Kuka Systems has installed a modular production hall at MAN Truck & Bus that can build 50,000 battery packs annually, with scope to double that output.

The facility uses autonomous mobile robots and decoupled stations to increase flexibility, giving manufacturers more room to adapt as technologies and volumes change.

Robotics are also beginning to play a role in disassembly and recycling. In the DeMoBat project at Fraunhofer IPA, Kuka robots are used to dismantle used battery packs, handling diverse designs under real industrial conditions to recover valuable materials safely and efficiently.

The battery market is attracting growing interest from automation suppliers who want to be part of the build-out, working alongside manufacturers to develop scalable production systems.

Comau, the Italian robotics and automation company, has joined the SPRINT project, part of the EU’s Horizon Europe programme, to help develop quasi-solid-state sodium-ion batteries for stationary energy storage.

Although the work is focused on energy technologies rather than robotics, Comau’s role highlights how automation expertise is being drawn into the sector.

The 46-month project is exploring manufacturing processes for sodium-ion cells that use sodium iron phosphate and polymer electrolytes.

Comau is tasked with feasibility studies, process optimization, and designing roadmaps to scale production into industrial environments.

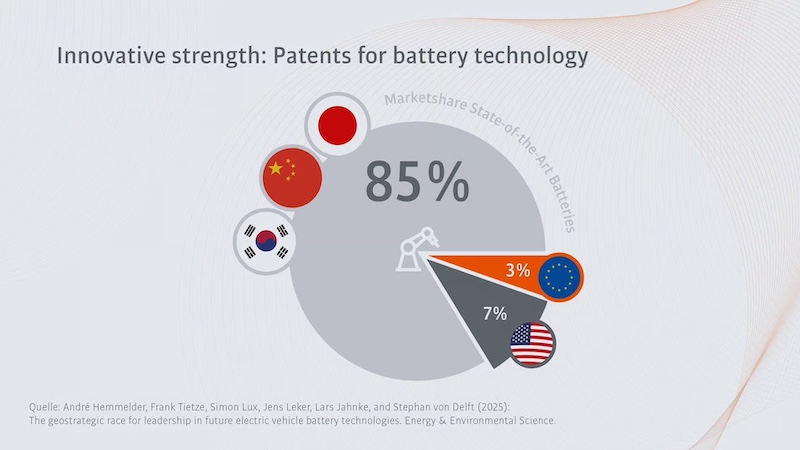

The aim is to cut costs per kilowatt-hour, extend battery life cycles, and increase European autonomy by using materials available in the region.

By engaging in projects like SPRINT, Comau is aligning with European strategies for electrification and sustainability, even if robotics is not the headline element.

The company is already active in industry associations such as the European Battery Alliance and Batteries European Partnership Association, positioning itself to play a role in how Europe builds its energy storage base.

For both Kuka and Comau, the message is similar: battery manufacturing is entering a phase of rapid expansion, and automation technologies will be integral to making that growth possible.