Fanuc America highlighted its latest automation technologies at FABTECH 2025 in Chicago, demonstrating how robotics, CNC systems, and collaborative automation can boost productivity and address labor shortages.

At its main booth, Fanuc presented robotic welding demonstrations aimed at small and mid-sized manufacturers.

In one setup, two CRX-10iA cobots worked together to assemble, weld and deburr a washer and nut component, while a CRX-30iA equipped with 3DV/200 vision technology handled the finished part.

The IP67-rated cobots featured hand guidance and drag-and-drop programming to support fast redeployment.

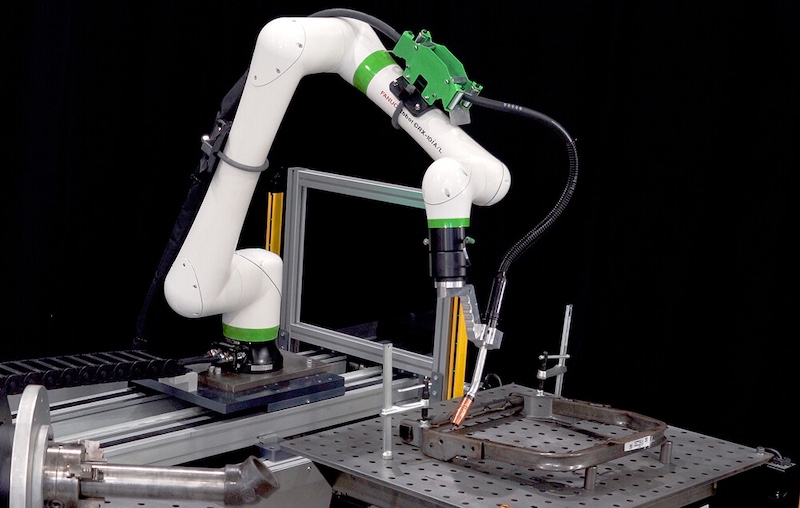

Other welding demonstrations included coordinated multi-arm welding with the new M-950/500F-28A material handling robot presenting an excavator bucket to two Arc Mate robots, and a CRX-10iA/L on a 7th axis rail servicing two operator stations in a compact arc welding cell.

Fanuc also showed the M-810/270F-27B robot in a wet machining application, milling and drilling aluminum stock, and the M-800iB robot integrated with laser cutting technology for precision perimeter cuts.

In addition to welding and machining, Fanuc showcased CNC systems optimized for laser applications and unveiled its Alpha i-D Servo System.

At its paint booth, Fanuc demonstrated industrial painting robots and cobots handling high-mix, low-volume work.

A CRX-10iA/L simulated painting electric guitar bodies using Fanuc’s 3DV iRVision, while a CRX-20iA/L cobot handled loading and unloading tasks with iRPickTool software. Fanuc also highlighted scalable paint automation for automotive, aerospace, and general manufacturing.

Eric Potter, general manager, robot application engineering segment, Fanuc America, says: “As manufacturers of all sizes face increasing demands for flexibility and efficiency in their production process, Fanuc continues to lead with automation solutions that are smart, scalable and easy to use.

“FABTECH 2025 is an ideal venue to demonstrate how our robotic and CNC technologies can help our customers solve real-world product challenges and drive long-term success.”

Fanuc experts also participated in conference sessions during the event.