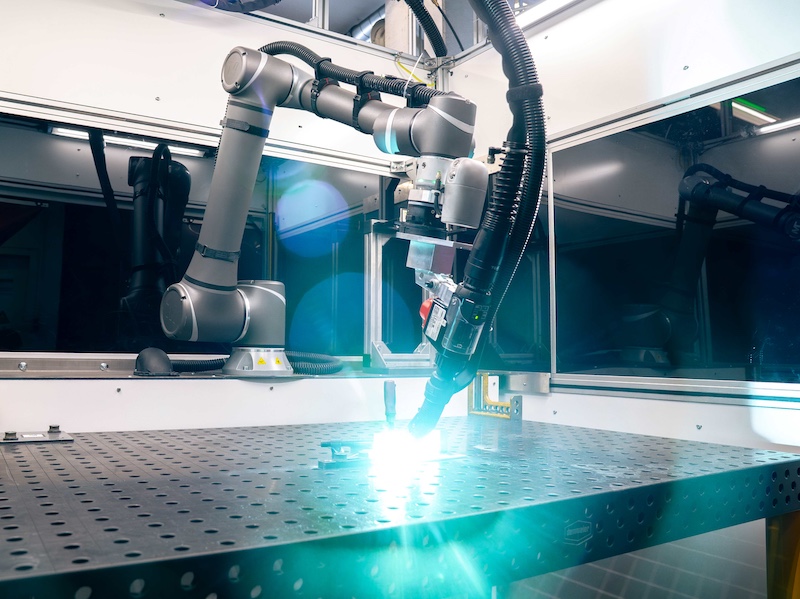

Gessmann will be presenting its newly developed cobot welding cell with the TM12S from its partner Techman at Blechexpo 2025 in Hall 9, Booth 9227.

The flexible and ready-to-use complete solution was specially designed for the production of small and medium series with frequently changing components.

In view of the shortage of skilled workers and increasing demands for variety, Gessmann offers a future-proof answer to the challenges of modern production processes with the TM12S cobot welding cell.

“The welding system we previously used in our own factory was both oversized and overloaded for the complex technical and changing requirements. We incorporated this experience directly into the development of the cobot welding cell,” explains Steffen Kuhnle, head of robotics at Gessmann.

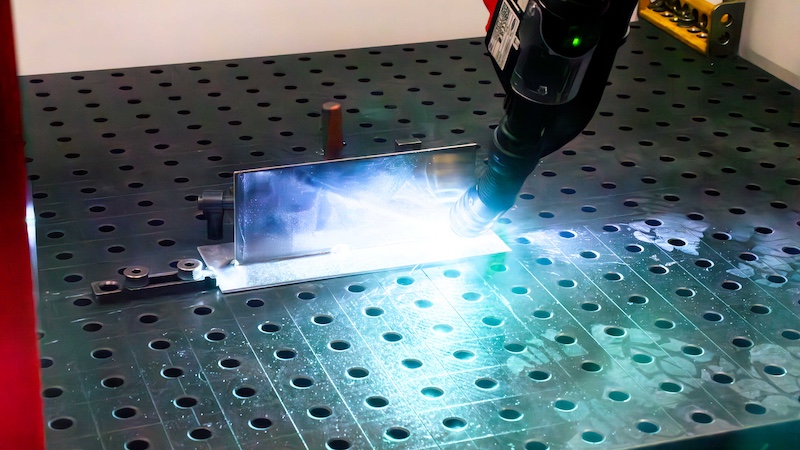

The new TM12S can be seamlessly integrated into existing manufacturing processes and has already proven itself in Gessmann’s own production environment as a flexible and cost-efficient solution. It supports common welding processes such as MIG, MAG, and TIG and is ideal for processing steel, stainless steel, and aluminium.

Flexible automation for changing requirements

The TM12S combines state-of-the-art collaborative robotics with an innovative tool changer system, delivering maximum flexibility and efficiency. A key feature of the system is the integrated camera, which can be flexibly aligned to enable precise component positioning and to simplify adaptation to different geometries.

Unlike many competing products that lack a camera, the combination with the tool changer allows free positioning of the camera. This is particularly advantageous for process monitoring and quality assurance.

The welding cell also meets all safety requirements in accordance with the CE standard and is certified by DEKRA (TÜV).

“It is also possible to integrate different welding devices. If there are no specific requirements in this regard, we rely on the proven systems from Fronius,” Kuhnle points out.

Thanks to the integrated tool changer, the modular TM12S can be used not only for welding tasks, but also for other automation tasks such as gripping, positioning, or handling.

The specially developed Gessmann user interface enables intuitive system control, meaning operators do not require in-depth knowledge of robotics to use it safely and efficiently. However, the expertise of a qualified welding specialist remains essential for the precise adjustment of welding parameters and quality assessment.

“We also offer targeted training courses for cobot applications to help users get started more easily and to increase acceptance,” emphasises Kuhnle.

Market readiness and public premiere at Blechexpo 2025

With the TM12S, Gessmann once again underlines its technological expertise in collaborative robotics and human–machine interfaces (HMI). Our experts are offering a forward-looking complete solution that is both safe and cost-efficient. The TM12S is already in production, available in multiple units, and can be ordered immediately.

“We are presenting the system to the public for the first time at this year’s Blechexpo. Visitors will be able to see it in live operation during on-site demonstrations in Hall 9, Stand 9227,” says Kuhnle.