In today’s competitive manufacturing landscape, SCARA robots have emerged as the backbone of modern production automation.

These versatile machines are transforming everything from electronics assembly to food packaging, but here’s the thing – choosing the wrong robot can cost you more than just money.

I’ve seen companies struggle with underperforming systems simply because they didn’t understand what they were buying.

The stakes are high. A poorly selected robot can bottleneck your entire production line, while the right choice can boost efficiency by 40% or more.

That’s why I’m sharing this practical guide – to help you navigate the technical maze and make a decision that actually works for your specific needs.

Key Technical Specifications of SCARA Robots

Understanding the Core Parameters

When evaluating SCARA robots, you need to focus on five critical specifications that will make or break your automation project:

Payload Capacity

- Light-duty: 1-5 kg (electronics, small parts assembly)

- Medium-duty: 5-15 kg (automotive components, packaging)

- Heavy-duty: 15+ kg (large assemblies, material handling)

Working Envelope The horizontal reach typically ranges from 300mm to 1200mm, while vertical stroke varies between 100mm to 400mm.

But here’s what most people miss – it’s not just about maximum reach, it’s about the usable workspace within your production constraints.

Pro Tip: Always plan for 80% of maximum payload and reach. This gives you a safety margin and ensures consistent performance throughout the robot’s lifecycle.

Repeatability and Accuracy

- Standard SCARA robots: ±0.02-0.05mm repeatability

- High-precision models: ±0.01mm or better

- Accuracy: typically 2-3x the repeatability value

Cycle Time Performance: Modern SCARA robots can achieve cycle times as low as 0.3 seconds for simple pick-and-place operations. However, real-world performance depends heavily on:

- Acceleration/deceleration profiles

- Path complexity

- Settling time requirements

Speed vs. Precision Trade-offs

Here’s something they don’t tell you in the brochures: faster isn’t always better. Some manufacturers bought the fastest robot available, only to discover they couldn’t use that speed due to vibration issues.

The sweet spot is usually 70-80% of maximum rated speed for production applications.

Selection Criteria for Production Tasks

Matching Robots to Applications

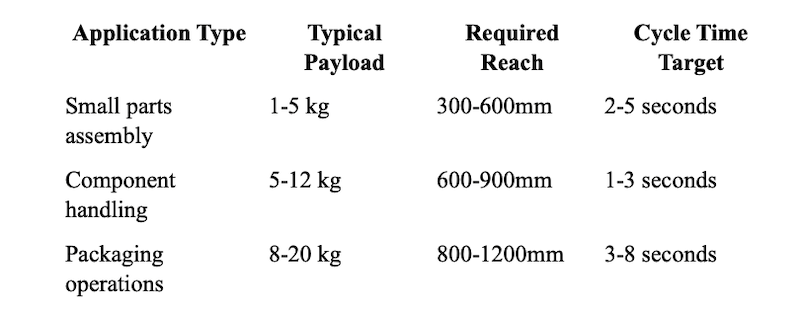

Different production tasks demand different robot characteristics. Let me break this down by application type:

Assembly Operations

Key Requirements:

- High repeatability (±0.01-0.02mm)

- Moderate payload (2-8 kg)

- Multiple I/O ports for tooling

- Vision system integration capability

Example: Electronics assembly typically requires robots with 400-600mm reach and sub-0.02mm repeatability.

Pick and Place Operations

Key Requirements:

- High speed (cycle times under 1 second)

- Moderate accuracy requirements

- Robust end-effector mounting

- Excellent path planning capabilities

Packaging and Palletizing

Key Requirements:

- Higher payload capacity (10-20 kg)

- Extended reach (800-1200mm)

- Robust construction for continuous operation

- Simple programming interface

Workspace Analysis Methodology

Before you even look at robot specifications, you need to map your workspace. Here’s my proven approach:

1. Map the physical constraints

- Available floor space

- Overhead clearance

- Safety zone requirements

- Integration with existing equipment

2. Analyze the work envelope

- Part pickup/dropoff locations

- Tool change positions

- Maintenance access points

3. Calculate cycle time requirements

- Production targets

- Changeover time allowances

- Uptime expectations

Analysis of Leading Manufacturers

Market Landscape Overview

The SCARA robot market is dominated by several key players, each with distinct engineering philosophies and strengths:

Japanese Manufacturers (Epson, Yamaha, Denso)

- Strengths: Exceptional build quality, high-speed capabilities

- Focus: Electronics and precision assembly applications

- Typical pricing: Premium segment

European Manufacturers (ABB, KUKA)

- Strengths: Robust industrial designs, comprehensive software ecosystems

- Focus: Heavy-duty applications, automotive industry

- Typical pricing: Mid to premium segment

Emerging Players (Chinese and Korean brands)

- Strengths: Cost-effective solutions, rapid customization

- Focus: High-volume, cost-sensitive applications

- Typical pricing: Budget to mid-range

Technical Differentiation Factors

What really sets manufacturers apart isn’t just the hardware – it’s the control systems and software integration. Some robots excel at high-speed operations but struggle with complex path planning. Others offer incredible precision but at the cost of throughput.

Reality Check: The “best” robot is the one that fits your specific application requirements and budget constraints, not necessarily the one with the highest specifications.

Service and Support Considerations

Don’t underestimate this factor. Your production line may shut down for days because of poor technical support. Consider:

- Local service availability

- Spare parts inventory

- Training programs

- Software update policies

Economic Efficiency Calculation

ROI Methodology for SCARA Implementation

Let’s get practical about the numbers. Here’s how to calculate whether a SCARA robot makes financial sense:

Direct Cost Savings:

- Labor cost reduction: $50,000-80,000 per operator per year

- Quality improvement: 2-5% reduction in defect rates

- Throughput increase: 20-40% typical improvement

Implementation Costs:

- Robot hardware: $25,000-100,000 depending on specifications

- Integration and setup: $15,000-50,000

- Training and commissioning: $5,000-15,000

Typical Payback Period:

- High-volume applications: 8-18 months

- Medium-volume applications: 18-36 months

- Low-volume/high-mix: 24-48 months

Hidden Cost Factors

Watch out for these often-overlooked expenses:

- Annual maintenance: 8-12% of initial robot cost

- Software licensing: Ongoing fees for advanced features

- Facility modifications: Power, compressed air, safety systems

- Process optimization: Continuous improvement costs

Practical Selection Recommendations

The SCARA Selection Checklist

Based on 15+ years of robotics integration experience, here’s your step-by-step selection process:

Phase 1: Requirements Definition

Define your application clearly

- What parts are you handling?

- What’s the required cycle time?

- What quality standards must be met?

Quantify performance requirements

- Payload with safety margin

- Working envelope with clearances

- Accuracy and repeatability needs

Phase 2: Technical Evaluation

Create a technical comparison matrix

- Weight each specification by importance

- Include total cost of ownership

- Factor in local support capabilities

Conduct proof-of-concept testing

- Test with actual parts when possible

- Validate cycle times under realistic conditions

- Assess programming complexity

Phase 3: Implementation Planning

Plan for integration

- Coordinate with existing systems

- Plan operator training programs

- Establish maintenance procedures

Working with Suppliers and Integrators

Here’s something crucial: choose your integrator as carefully as your robot. A skilled integrator can make an average robot perform exceptionally, while a poor integrator can ruin even the best hardware.

Key questions to ask integrators:

- How many similar applications have you completed?

- What’s your typical project timeline?

- What ongoing support do you provide?

- Can you provide local references?

Implementation Best Practices

Start Small, Think Big: Don’t try to automate everything at once. Begin with a pilot application that’s likely to succeed, then expand based on lessons learned.

Plan for Flexibility: Choose robots and systems that can adapt to future product changes. The manufacturing landscape evolves quickly, and your automation should evolve with it.

Invest in Training: Your operators and maintenance staff need proper training. Budget 10-15% of your project cost for comprehensive training programs.

Final Thoughts

Understanding what is a scara robot and its capabilities is just the beginning. The real challenge lies in matching those capabilities to your specific production requirements and making a selection that delivers long-term value.

The key to successful SCARA robot selection isn’t finding the “perfect” robot – it’s finding the right robot for your specific needs, budget, and operational constraints.

Take time to understand your requirements, evaluate options thoroughly, and plan for successful integration.