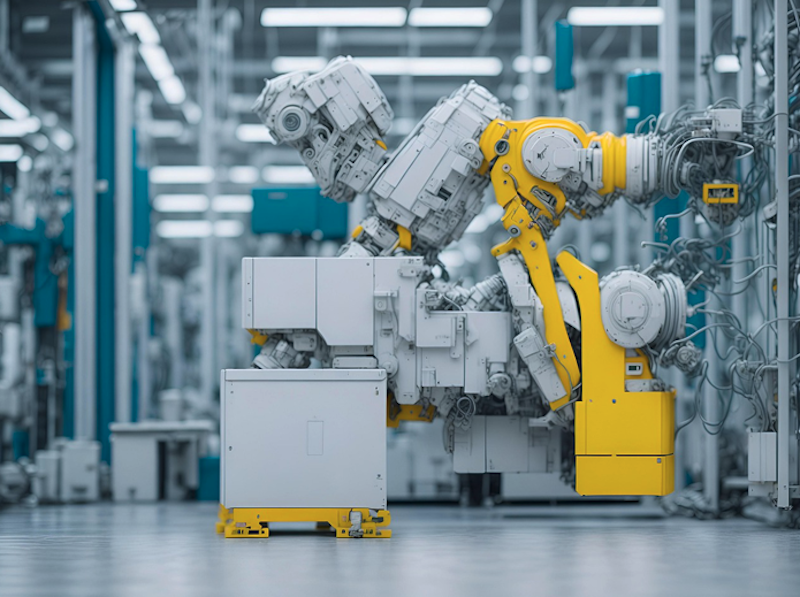

AI-driven robotics can revolutionize production efficiency when implemented correctly. The challenge is reaching this point without encountering one of the many obstacles that lie in your path.

To that end, here are the main strategies needed for readiness, taking you from discovery to scaled integration as seamlessly as possible.

Assessing Your Factory’s Current AI Readiness

Begin by evaluating your factory’s ability to support AI-powered robotics. Gaps in data, systems, or leadership alignment can slow progress. A clear understanding of where you stand helps focus efforts.

Key areas to review include:

- Existing operational technologies – are they flexible for upgrades?

- Data quality and accessibility – is production data accurate and organized?

- Workforce capabilities – does the team have basic automation skills?

- Leadership support – is there buy-in for significant technological changes?

If in doubt, complete an AI readiness checklist to identify strengths and weaknesses clearly. This ensures that your resources target the right improvements before implementation begins.

Starting with a solid assessment creates a foundation for success without wasting time or effort on unfeasible plans.

Building Reliable Data Pipelines for Robotics Integration

Strong data pipelines ensure AI-powered robotics functions effectively. Poor data quality or disorganized systems can undermine results, while high-quality data guarantees success. Focus on building reliable pathways to collect, process, and share information seamlessly.

To strengthen data pipelines:

- Standardize production data formats to reduce errors

- Implement sensors where real-time tracking is lacking

- Use scalable storage solutions that handle growing datasets

- Invest in tools for analyzing and cleaning raw operational data

Clear and accessible data allows AI systems to make accurate decisions quickly. It also minimizes downtime caused by misinformation or gaps in inputs.

Building these pipelines upfront reduces delays during later phases like piloting or scaling, setting a foundation for smooth operations as the project evolves.

Aligning OT and IT Systems Without Overhauls

Operational Technology (OT) and Information Technology (IT) integration is essential for AI robotics, a market that’s set to top $22.63 billion this year. Mismatched systems can cause disruptions, but full overhauls aren’t always necessary. Focus on creating bridges between existing setups instead.

To align these:

- Identify overlaps between OT and IT functions to streamline connections

- Use middleware solutions to translate data formats across platforms

- Ensure network security protocols protect both operational and information systems

- Establish centralized monitoring tools for visibility into both sides

Well-aligned OT and IT systems allow seamless communication between robots, software, and operators, maximizing efficiency without requiring complete system replacements.

Pre-Pilot Safety and Risk Evaluations That Matter

Before deploying AI-powered robotics, safety validation is crucial. Even minor oversights can lead to costly or dangerous incidents. A thorough risk assessment ensures the pilot phase runs smoothly.

Important safety steps:

- Inspect existing equipment for compatibility with robotic systems

- Evaluate physical layouts to identify hazards like tight spaces or obstructions

- Test emergency stop mechanisms and fail-safe protocols for reliability

- Train employees on interacting safely with automated machines with the use of an AI lesson plan generator to handle employee training in-house, rather than outsourcing

Regular checks and adjustments during the pilot help catch issues early, minimizing risks as operations progress.

Prioritizing safety not only protects workers but also builds confidence in new technologies, making it easier to gain buy-in from teams and leadership alike.

Choosing Vendors with the Right Expertise for Brownfield Plants

Selecting the right vendor ensures your factory’s unique needs are met. Brownfield plants often have legacy systems and constraints that require tailored solutions.

When evaluating vendors, look for:

- Proven experience working with older equipment and infrastructures

- The ability to customize AI robotics for your specific industry and workflows

- Support services like training, maintenance, and troubleshooting assistance

- Transparency about implementation timelines, costs, and potential challenges

Vendors with a strong track record in similar environments can provide insights that minimize disruptions during integration. Careful selection saves time by avoiding mismatched capabilities or unmet expectations in the long run.

Wrapping Up

Preparing a factory for AI-powered robotics requires careful planning and attention to detail. Addressing readiness, data pipelines, system alignment, safety, and vendor selection ensures a strong foundation.

Each step builds on the last to create a seamless integration process. By identifying gaps early and prioritizing solutions tailored to your plant’s needs, you set yourself up for long-term success.

The effort invested upfront leads to smoother transitions and maximized benefits when scaling AI-driven robotics across operations.

Main image by Pete Linforth from Pixabay