Apple, the maker of Mac and iPhone devices and one of the world’s largest tech companies, says it will invest an additional $100 billion into its manufacturing operations across the United States.

Apple has just announced the new $100 billion investment as a “commitment to America”, adding that it is a “significant acceleration” of its US investment that now totals $600 billion over the next four years.

The announcement includes the ambitious new American Manufacturing Program (AMP), dedicated to bringing even more of Apple’s supply chain and advanced manufacturing to the US.

Through AMP, Apple will increase its investment across America and incentivize global companies to manufacture even more critical components in the United States.

Tim Cook, Apple’s CEO, says: “Today, we’re proud to increase our investments across the United States to $600 billion over four years and launch our new American Manufacturing Program.

“This includes new and expanded work with 10 companies across America. They produce components that are used in Apple products sold all over the world, and we’re grateful to the President (Trump) for his support.”

Apple parts and components manufactured in the US ship to customers around the world; in fact, roughly two-thirds of the components made in the US are exported to customers outside the US.

Today, Apple partners with thousands of suppliers across all 50 states, supporting more than 450,000 supplier and partner jobs.

In the next four years, Apple plans to directly hire 20,000 people in the US – the vast majority focused on R&D, silicon engineering, software development, and AI and machine learning.

Apple American manufacturing program

Apple is working with its suppliers to accelerate manufacturing in the US through the new American Manufacturing Program.

The first AMP partners include Corning, Coherent, GlobalWafers America (GWA), Applied Materials, Texas Instruments (TI), Samsung, GlobalFoundries, Amkor, and Broadcom. This builds on Apple’s July commitment to buy American-made rare earth magnets from MP Materials.

The American Manufacturing Program will help fund a major expansion of Apple’s long-standing partnership with Corning, bringing the world’s largest and most advanced smartphone glass production line to a factory in Harrodsburg, Kentucky.

The expansion means that soon, every iPhone and Apple Watch sold around the world will be built with Kentucky-made cover glass. The two companies will also open a new Apple-Corning Innovation Center in Kentucky.

Apple has also entered into a new multiyear agreement with Coherent, a long-standing partner that produces the VCSEL lasers that enable multiple features – including Face ID – on iPhone and iPad devices shipped around the world. This work takes place at Coherent’s Sherman, Texas, facility.

In July, Apple also committed to buying American-made rare earth magnets developed by MP Materials – the only fully integrated rare earth producer in the United States – significantly expanding their flagship Independence facility in Fort Worth, Texas.

These magnets will become part of Apple devices shipped around the world. The two companies will also establish a cutting-edge rare earth recycling line in Mountain Pass, California.

Apple expands end-to-end American silicon supply chain

With these new partnerships, Apple is leading the creation of an end-to-end silicon supply chain in the United States, with partners in every key aspect of silicon production.

This US silicon supply chain is on track to produce more than 19 billion chips for Apple products in 2025.

That includes TSMC in Arizona, which is producing tens of millions of chips for Apple using one of the most advanced process technologies in America. Apple is this factory’s first and largest customer.

Sabih Khan, Apple’s chief operating officer, says: “Apple engineers work closely with suppliers across the United States to create silicon chips that are on the leading edge of innovation.

“We’re committed to supporting US suppliers involved in every key stage of the chip-making process – from the earliest stages of research and development, to final fabrication and packaging.

“We want America to lead in this critical industry, and we’re expanding our efforts to grow a silicon manufacturing ecosystem that will benefit innovators across America.”

Apple’s partners and initiatives across manufacturing

GlobalWafers

Wafers are the building block of any silicon chip, and Apple is partnering with GlobalWafers America in Sherman, Texas, to produce advanced wafers for use in US-based semiconductor fabs for the first time.

American chip fabs like TSMC in Phoenix, Arizona, and Texas Instruments in Sherman, Texas, will use GWA’s 300 mm wafers to produce chips for iPhone and iPad devices sold in the US and around the world.

GWA uses silicon from US sources, including from Corning’s Hemlock Semiconductor, to produce the world’s most advanced silicon wafers.

Apple Materials

Apple is also partnering directly with Applied Materials to boost the production of semiconductor manufacturing equipment in the US. The Applied site in Austin, Texas, is a pivotal hub for manufacturing cutting-edge chip equipment.

Texas Instruments

Fabs take bare wafers and turn them into chips. Apple and Texas Instruments are expanding their partnership to increase future product collaboration and critical US capacity for this work.

Apple is making a new commitment with TI, which will support additional tool installations at its facility in Lehi, Utah, and a new facility in Sherman, Texas.

These facilities are home to TI’s most advanced process technologies and use American-made chip manufacturing equipment from Applied Materials’ factory in Austin, as well as advanced silicon wafers from GlobalWafers America.

These facilities will manufacture critical foundational semiconductors used for Apple products, including iPhone devices shipped in the US and around the world.

Samsung

Apple is also working with Samsung at its fab in Austin, Texas, to launch an innovative new technology for making chips, which has never been used before anywhere in the world.

By bringing this technology to the US first, this facility will supply chips that optimize power and performance of Apple products, including iPhone devices shipped all over the world.

GlobalFoundries

GlobalFoundries and Apple have also entered an agreement to bring more semiconductor manufacturing to the United States, focused on manufacturing cutting-edge wireless technologies and advanced power management – critical technologies that enable longer battery life and enhanced connectivity in Apple devices.

The partnership will bring new capabilities, jobs, and technology to the GlobalFoundries semiconductor facility in Malta, New York.

Amkor

Packaging is the final critical step in manufacturing silicon chips. Apple is investing in Amkor’s new advanced chip packaging and test facility in Arizona, and will be its first and largest customer.

This will accelerate the development of packaging capabilities in America, meaningfully strengthening the semiconductor supply chain in the US.

This facility will package and test Apple silicon manufactured at the nearby TSMC fab, and create chips used in iPhone devices shipped around the world.

Apple is also working with Broadcom and GlobalFoundries to develop and manufacture additional cellular semiconductor components in the US. These components are crucial for 5G communications in Apple products.

New and expanded facilities across the US

Earlier this year, construction began in Houston on the new factory supporting production of advanced Apple servers, and in July, the facility produced its first test unit. The 250,000-square-foot server manufacturing facility is slated to begin mass production in 2026.

Previously manufactured outside the US, the servers from Houston will play a key role in powering Apple Intelligence, and are the foundation of Private Cloud Compute, which combines powerful AI processing with the most advanced security architecture ever deployed at scale for AI cloud computing.

The servers bring together years of R&D by Apple engineers, and deliver the industry-leading security and performance of Apple silicon to the data center.

In Detroit, registration is now open for the new Apple Manufacturing Academy, which was announced in February and is set to open on August 19.

The academy will offer consultations and courses to small and medium-sized business on how they can implement advanced manufacturing and AI into their manufacturing programs.

Construction is also under way in Maiden, North Carolina, where Apple is expanding the capacity of its data center with a significant investment in its state-of-the-art facility that supports North American users of Apple services.

The expansion builds on more than $5 billion that Apple has already invested in Catawba County.

Apple’s Maiden facility supports Apple’s services such as iCloud, the App Store, Apple Music, iMessage, Apple TV+, Apple Sports, and more. The expanded capacity will also help support the growth of Apple Intelligence.

As with all of Apple’s facilities, the data center is powered by 100 percent renewable energy sourced from Apple-created projects in the region.

Apple is also expanding data center capacity in states across the country, with construction underway in Iowa, Nevada, and Oregon.

Meanwhile, construction continues on Apple’s second campus in Austin. Apple has more than 13,000 team members across Texas, including thousands already working from the three completed office buildings, which exceed 1 million square feet.

The three buildings currently under construction include an expansive new R&D lab space for Apple’s Hardware Engineering, Hardware Technology, and Software Engineering teams.

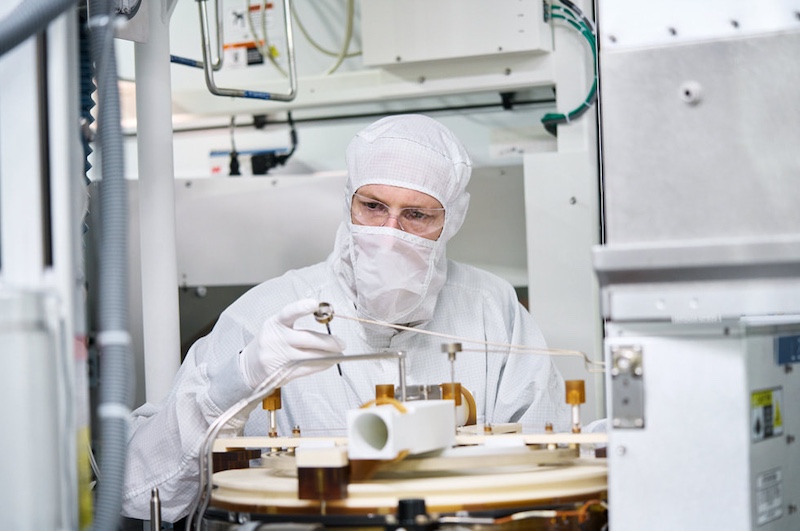

Main image: Through its new American Manufacturing Program, Apple is working with American suppliers like Corning to accelerate US manufacturing.