As the space ecosystem continues to grow and diversify, bringing with it a new economic era, it has become essential to address issues related to space sustainability, to ensure that we can use space in a responsible way over the long term.

The multinational technology firm GMV has become prominent in the space industry, with a firm commitment to performing its space-related activities in a socially and environmentally respectful way.

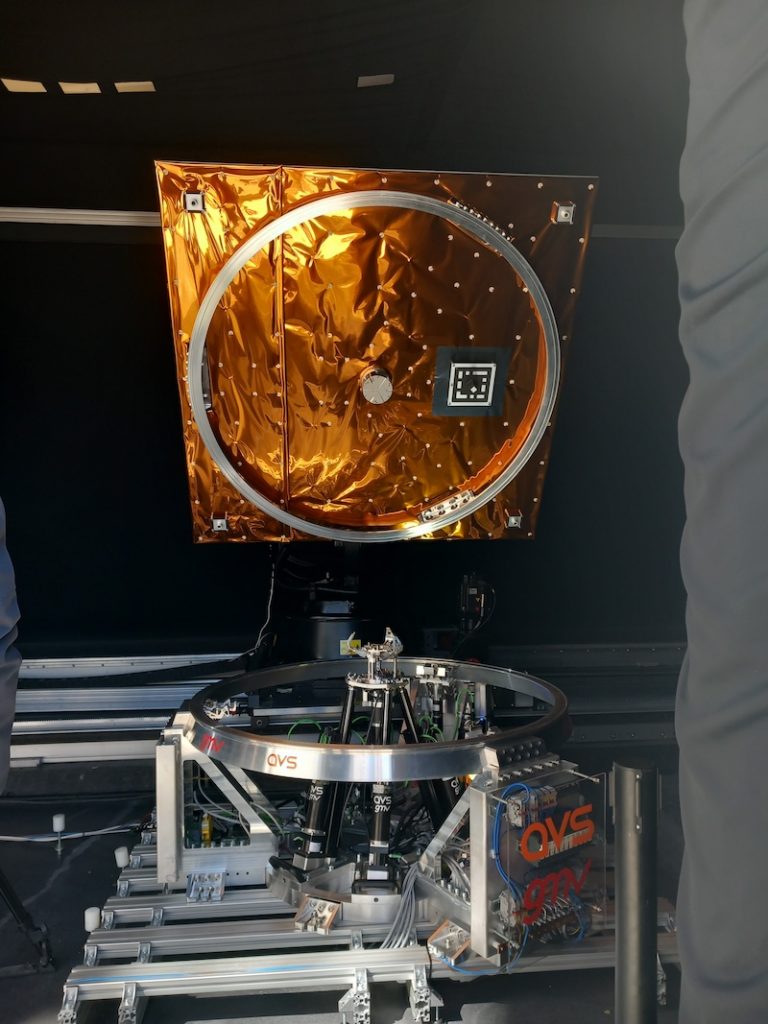

The company is now performing work and testing at its exclusive “platform-art” test bench. This work involves a range of important technologies for removing space debris, and for performing in-orbit maintenance, refueling, and assembly of complex infrastructure and elements.

In recent years, the space industry has experienced a profound transformation, driven by public-sector initiatives as well as private investment.

Specific concepts from the New Space paradigm are now playing a fundamental role in this evolution, such as reducing costs through economies of scale, intensive use of commercially available off-the-shelf (COTS) components, standardization, and acceleration of development cycles.

More than 17,000 satellites have been launched into space, and about 11,500 of them are still there, with more than 9,000 still in operation.

In the near future, this number will continue to increase with the launching of mega-constellations, which are made up of hundreds or even thousands of new satellites.

To confront the demands imposed by these rising numbers, there will be a need for an integrated inorbit transport and services ecosystem, developed under the appropriate conditions.

Firstly, there must be a commitment to performing space-related activities in a socially and environmentally respectful way. This includes work performed by the European Commission (EC) on new space legislation and the European Space Agency’s Zero-Debris approach, because initiatives like these are essential for achieving space sustainability.

Secondly, there is a need for technologies that are able to satisfy new, emerging needs, in terms of both performance and costs.

As part of this focus on sustainability, the ESA and the European Union have taken on a proactive role by preparing the new generation of Earth observation satellites in a way that will allow their removal at the end of their useful life, or if they malfunction.

Four of those satellites belonging to the new generation of Earth observation missions (Copernicus) are already regulated by the ESA’s design-for-removal interface requirements document, and they are already being equipped with the equipment known as MICE (a mechanical interface for end-of-life capture, developed in Spain by GMV in collaboration with AVS), along with a series of navigation assistance devices.

This will facilitate the capture and removal from orbit of non-cooperative satellites in the future, when they have reached the end of their useful life or malfunction.

Also in collaboration with AVS as part of an ESA contract, GMV is developing the CAT capture system, which is an essential element of active removal of the Copernicus satellites already equipped with the MICE interface, within the newly established 5year limit.

If we want to continue making use of space in the future, it is essential to see it as a ecosystem that must be protected, just like our oceans and forests.

We are not always aware of how much we depend upon satellites. However, each of us interacts with about 100 satellites every day, which provide us with essential services such as Earth observation, meteorology, telecommunications, satellite navigation, geo-positioning, bank transfers, and so on.

All of this highlights the importance of viewing space as a new ecosystem to be protected.

GMV is continuing its work on new technologies

At its exclusive platform-art robotics laboratory, GMV is now testing specific technologies that will play a key role in the European context, while contributing to the future ecosystem of in-orbit transport, maintenance, and debris removal.

Robotic technologies that allow capture and removal by the service provider, such as development of a compatible end effector and grippers, optical navigation, avionics, and control functions, are among the elements that have reached an advanced phase of development.

All of these elements are integrated into a unified system know as CAT: Return Capture Payload Bay. CAT is a robotic space debris removal system that has been designed as a specialized payload.

It acts in conjunction with a service vehicle and its guidance, navigation and control (GNC) system, to allow approach, synchronization, capture, stabilization, and securement of the final assembly, so that the malfunctioning or uncontrolled spacecraft can be removed from orbit.

It consists of six arms and a gripper that can capture the non-operational satellite that must be removed.

In-orbit maintenance and assembly will also play an important role in the economic future of space, and will contribute to achieving a sustainable space ecosystem, by optimizing launch costs and facilitating the design of new flexible and scalable missions.

In this area, launching and inorbit assembly of large structures will become a recurring operation. The ESA is now funding development of a multiarm assembly robot known as MIRROR.

GMV is leading this project, and it has now designed the first European prototype for a self-relocatable robotics system for in-orbit operations.

Specifically, this equipment can perform inorbit assembly of large structures while also offering services for maintenance, repair, and updating for a variety of space vehicles and infrastructure elements.

Finally, but no less importantly, the ability to provide inorbit services can be a way of prolonging useful life, improving performance, and even allowing dynamic reconfiguration of mission objectives.

In this area, the design of modular spacecraft and the capacity for refueling are important factors. The ASSIST mechanical device is the first and most advanced European initiative designed to standardize refueling interfaces for satellites.

Based on an open-interface approach, this initiative is currently in progress, to prepare for its eventual inorbit demonstration.

GMV is a privately owned technology business group founded in 1984 and trading on a worldwide scale in the following sectors: Space, Aeronautics, Defense and Security, Cybersecurity, Intelligent Transportation Systems, Automotive, Healthcare, Telecommunications and IT for government authorities and major corporations.

In 2022, the company posted revenues of over €311 million. Working with a staff of over 3,000, the company now runs subsidiaries in Spain, USA, Germany, France, Poland, Portugal, Romania, UK, The Netherlands, Belgium, Malaysia, and Colombia.

Seventy five percent of its turnover comes from international projects on all five continents. The company’s growth strategy is based on continuous innovation, and it plows back 10 percent of its turnover into in-house R&D.

GMV has reached CMMI level 5, the world’s most prestigious model in terms of enhancing an organization’s process capability, and it has numerous international patents.

Currently, GMV claims to be the world’s number-one independent supplier of ground control systems for commercial telecommunications satellite operators and the European leader in the ground segment of Global Navigation Satellite Systems (EGNOS and Galileo).

It is also the primary provider of C41 command and control systems for the Spanish Army and the leading national provider of telematic systems for public transport.

For over 20 years now, it has also been a provider of telematics software, services, and systems in the automotive sector.

In the ICT sector it is benchmark provider of advanced cybersecurity, artificial intelligence and digital transformation solutions and services.

In 2024 GMV sets a new milestone on its growth: the company celebrates 40 years of history with the motto “Excellence and Beyond”, four decades of success based on talent, excellence, and innovation.