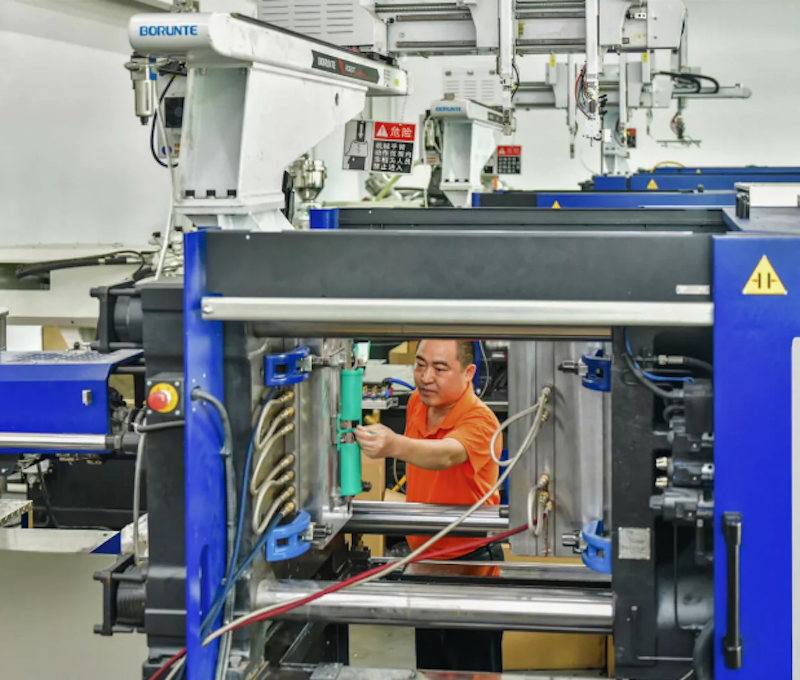

Injection molding is a manufacturing process for producing parts from both thermoplastic and thermoset materials.

Injection molding machines are used to inject molten plastic into a mold cavity, where it cools and hardens to the shape of the cavity.

There are many different types of injection molding machines, each with its own set of benefits. In this blog post, we will discuss the three most common types of injection molding machines: hydraulic, electric, and servo-electric. We will also discuss the benefits of each type of machine.

Plastic Injection Molding provides a versatile manufacturing process that can be used to produce parts from a wide variety of materials. Injection molding machines are available in a variety of different types, each with its own set of benefits.

In this blog post, we have discussed the three most common types of injection molding machines: hydraulic, electric, and servo-electric. A popular company that specializes in these moldings is 3ERP injection molding.

Hydraulic Injection Molding Machines

Hydraulic injection molding machines are the most common type of machine on the market. They are typically less expensive than electric or servo-electric machines, and they are easy to operate. Hydraulic injection molding machines use a hydraulic pump to generate pressure, which is then used to inject molten plastic into the mold cavity.

The Benefits of Hydraulic Injection Molding Machines

There are many benefits to using hydraulic injection molding machines. They are faster and more precise than other types of machines, they use less energy, and they create less noise.

Hydraulic machines are also easier to maintain, and they have a longer lifespan. In addition, hydraulic machines are more versatile and can be used for a variety of different products. As a result, they are an excellent choice for any business that is looking to improve its production process.

Electric Injection Molding Machines

Electric injection molding machines are becoming more popular in recent years. They are more energy-efficient than hydraulic machines, and they offer greater control over the injection process. Electric machines use an electric motor to generate pressure, which is then used to inject molten plastic into the mold cavity.

The Benefits of Electric Injection Molding Machines

Electric injection molding machines have many benefits over their hydraulic counterparts. They are more energy-efficient, which can lead to lower operating costs. They are also quieter and emit less emissions, making them more environmentally friendly.

In addition, electric machines are more precise, resulting in better-quality products. They are also easier to maintain and require less downtime for repairs. As a result, electric injection molding machines offer a number of advantages over hydraulic machines, making them the preferred choice for many manufacturers.

Servo-electric Injection Molding Machines

Servo-electric injection molding machines are the most advanced type of machine on the market. They are more energy-efficient than hydraulic or electric machines, and they offer greater control over the injection process. Servo-electric machines use a servo motor to generate pressure, which is then used to inject molten plastic into the mold cavity.

The Benefits of Servo-electric Injection Molding Machines

One of the most important advances in injection molding has been the servo-electric injection molding machine. These machines offer a number of advantages over their hydraulic counterparts, including reduced energy consumption, increased precision, and improved repeatability.

Servo-electric machines are powered by electric motors, which are more efficient than hydraulic pumps and can deliver precise control over injection pressure and speed. This allows for greater accuracy when molding complex parts with tight tolerances. In addition, servo-electric machines are much quieter than hydraulic machines, making them ideal for use in noise-sensitive environments.

Another advantage of servo-electric injection molding machines is that they are significantly smaller and lighter than hydraulic machines. This makes them easier to install and reduces the overall footprint of the injection molding operation. Additionally, servo-electric machines typically have a longer lifespan than hydraulic machines due to their simpler design and lack of moving parts.

Overall, servo-electric injection molding machines offer a number of advantages that make them the preferred choice for many applications. With their reduced energy consumption, increased precision, and improved repeatability, these machines can help to improve productivity and reduce costs.

Good Mix

All three types of injection molding machines have their own benefits. Hydraulic machines are the most common and the most affordable, while servo-electric machines are the most advanced and offer the greatest control over the injection process. Electric machines fall somewhere in between, offering a good mix of affordability and control.