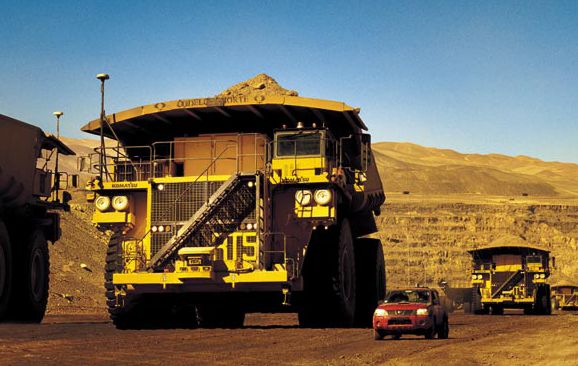

Global mining giant Rio Tinto is said to have increased productivity by 34 percent through the use of Komatsu autonomous trucks.

Rio Tinto has been testing and implementing autonomous technology for around a decade, and after a decade of using Komatsu’s massive driverless trucks, the company is integrating autonomous trains into its operations.

Komatsu’s vehicles are called autonomous haulage systems, or AHS. The AHS truck fleet is forecast to drive reductions in operating costs at Australia’s iron ore mines by up to $0.62 per ton by 2020, according to research company GlobalData.

Mining companies across the globe are increasingly embracing automation in their quest to boost efficiency and reduce human labor.

In Australia, automation in the mining industry began with the implementation of Komatsu’s Automatic Hauling System at Rio Tinto’s Pilbara iron ore operations in 2008.

Data and analytics company GlobalData predicts that AHS truck fleet will noticeably reduce operating costs at the country’s iron ore mines.

Rio Tinto, which is responsible for up to 40 percent of Australia’s iron ore production, has gradually expanded its AHS truck fleet from five in 2008 to 95 by the end of 2017. The company plans to increase the number further to around 150 trucks by 2020.

So far, Rio Tinto has invested over $2 billion into the installation of AHS trucks and robotics, with the majority of these at the company’s Pilbara iron ore operations.

Through these investments and upgrades, the company reported a 37 percent increase in the per person productivity between 2014 and 2017.

Ankita Awasthi, senior mining analyst at GlobalData, says: “AHS can have a significant impact in reducing the mining cost, which accounts for an average of 34 percent of the total operating cost.

“The key benefits of AHS trucks include improved haul truck utilization, alongside higher productivity.”

AHS trucks are only one part in Rio Tinto’s “Mine of the Future” program. Other proprietary technological advancements include:

- Automated Drilling System;

- AutoHaul;

- Mine Automation System; and

- 3D software technology.

The company implemented the world’s first AutoHaul rail network in the first quarter 2017, automating more than 60 percent of its rail network.

Other Australian iron ore miners, such as BHP and FMG, which together control up to 45 percent of the country’s iron ore supply, have deployed AHS trucks at their respective mining sites.

For example, in 2013, FMG initially deployed 54 AHS trucks and currently has 56 AHS trucks in operation, with its fleet expected to expand to 68 AHS trucks by 2020, while BHP is expected to add up to 50 by the same year.

Awasthi says: “While the numbers are still relatively small, the gradual increase in the AHS fleets is expected to have a noticeable impact on average operating costs for the major iron ore miners.

“In conjunction with other measures, GlobalData expects operating cost reductions on a per ton basis in the range of $0.50 to $0.62 by 2020 for the major iron ore miners, reducing the already low average from $13.63/t in 2017 to $13.07 in 2020.”