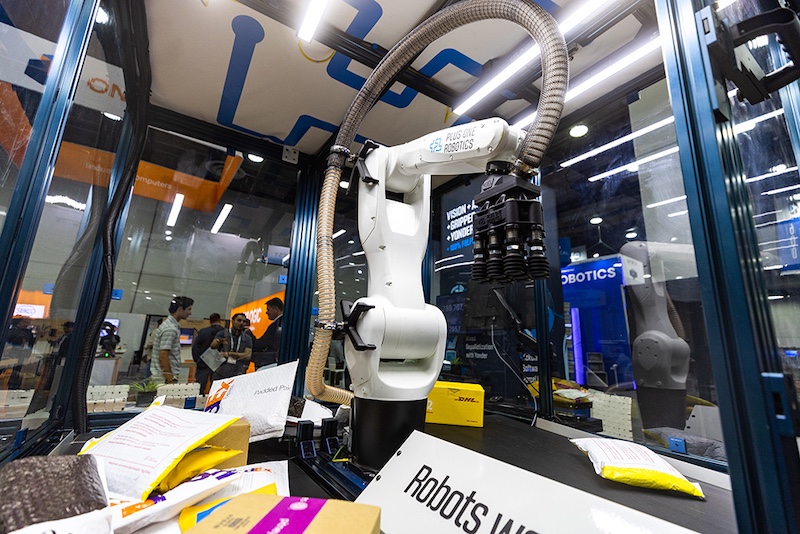

By Erik Nieves, co-founder and CEO of Plus One Robotics

The US decision to end the de minimis tariff exemption on packages under $800 has upended small package trade and set off a chain reaction in global shipping.

Postal operators across Europe, Asia and the Pacific have suspended deliveries to the US, leading to backlogs, surges in returns and rerouted freight.

For e-commerce retailers and warehouse operators, the sudden disruption is exposing just how fragile supply chains can be.

As trade routes shift and parcels pile up, automation is emerging as a stabilizing force. AI-driven robotics, supported by human-in-the-loop systems, give warehouses the flexibility to handle unpredictable spikes in volume without grinding to a halt.

In a moment when traditional processes are under strain, automation is proving essential to keeping goods moving.

Tariffs, trade and turmoil

Previously, millions of low-value items entered the US duty-free. Now, importers must prepay duties at rates that can exceed 25 percent, plus fixed surcharges ranging from $80 to $200 per parcel.

Letters, documents and gifts under $100 remain exempt, but the vast majority of e-commerce parcels no longer qualify for tax-free status. Facing uncertainty and new compliance burdens, international postal services have suspended US deliveries altogether.

This shock has ricocheted through the supply chain. Freight activity in early 2025 showed a 32.2 percent year-over-year increase in units shipped despite a 20 percent decline in total freight volume shipped, evidence that shippers are consolidating freight to minimize costs.

Air freight capacity between China and the US has dropped nearly 30 percent following the removal of the de minimis exemption. FedEx has reduced its transpacific outbound capacity by approximately 25% year-over-year in response to weakening demand.

UPS has shifted resources toward intra-Asia traffic as US-bound volumes wane, with its own data projecting capacity declines of more than 6% on Asia-US West Coast lanes.

These reductions underscore how tariffs and trade disruptions are reshaping the flow of goods across the Pacific and forcing carriers to recalibrate their networks.

Monthly order volatility has spiked 63.7 percent, while inventory levels climbed 4 percent year-over-year as businesses stockpile goods to hedge against uncertainty. Ocean freight rates are falling as importers balk at unpredictable costs and delays.

For warehouses, these dynamics manifest as unpredictable spikes, including waves of returned packages, delayed shipments arriving in clusters and sudden demand shifts. Many of these returns stem directly from the end of the de minimis exemption.

When duties are not prepaid, US consumers are often confronted with unexpected tariff bills at delivery and refuse their packages, leading to goods being sent back.

International posts that suspended service have also rerouted shipments back to origin, while stricter customs scrutiny has caused misdeclared parcels to be rejected.

Together these forces push unexpected volumes of returns into warehouse networks. Without automation, these surges risk overwhelming human labor capacity. With automation, they can be absorbed, redirected and managed in real time.

Human-in-the-loop robotics: The shock absorber for warehouse operations

Traditional automation, such as conveyor belts, AS/RS systems or pick-to-light systems, was designed to handle predictable operations. But these trade upheavals create a highly unpredictable environment.

In this context, AI-driven robotics with human-in-the-loop oversight do not replace those systems but augment them, adding the flexibility needed to handle unexpected flux.

In this approach, robots handle repetitive, high-throughput tasks and human workers intervene only when exceptions arise.

Robots equipped with AI-enabled vision systems sort, pick and palletize diverse parcels, while remote human supervisors monitor multiple robots at once, stepping in via the cloud when an edge case emerges.

This model delivers two critical advantages for disrupted environments. First, it provides a way to manage surges while staying consistent by automating to steady-state volumes and flexing with labor when needed.

Human-in-the-loop robotics can absorb a share of this surge capacity by allowing a small number of human overseers to manage multiple robots at once, reducing the need for large, rapid hiring pushes during unpredictable peaks.

Second, it reduces errors in volatile flows. AI systems excel at pattern recognition and adapt to shifting parcel mixes. Human-in-the-loop input ensures that when robots face anomalies such as odd shapes, damaged packages or mislabeled barcodes, operations don’t stall.

Automation’s economic rationale

The financial case for automation becomes stronger as volatility increases. According to Fortune Business Insights, the AI-in-warehousing market was valued at $10.27 billion in 2024 and is projected to reach $61.36 billion by 2032, growing at a CAGR of 25.2 percent.

The broader warehouse automation market is expected to reach $36.48 billion by 2028, nearly doubling from 2023. Retailers, logistics providers and manufacturers are urgently embracing this type of automation.

Tariffs sharpen the cost-benefit equation even further. Higher import duties increase landed costs, which squeezes margins.

Automation allows operators to offset these expenses by increasing throughput, lowering error rates and minimizing labor-related overhead without compromising service levels.

Six steps to automation success

For organizations looking to deploy automation amid this global disruption, the first place to start is strategy. Drawing on industry best practices, here are six foundational steps:

Get buy-in from the warehouse team. Early engagement with frontline workers is essential. Automation should be framed as a way to reduce physical strain, improve safety and elevate roles toward system oversight and troubleshooting.

Collaborate with stakeholders at every stage. From executives to IT teams, alignment on objectives and KPIs such as throughput gains or reduced turnover ensures that automation deployments meet broad organizational goals.

Consider risks and edge cases. Disruptions amplify variability. Fragile products, irregular parcels or volatile order volumes must be anticipated in vendor selection and workflow design.

Conduct thorough training and testing. AI-driven robotics improve with feedback loops. Training programs should emphasize both the refinement of machine learning and human readiness to adapt to evolving workflows.

Create a problem-solving strategy. Establish escalation paths for technical failures or process disruptions. Clear troubleshooting protocols prevent downtime from compounding during peak surges.

Train relentlessly. Continuous training and iterative improvement are the backbone of resilient operations. As tariffs, shipping patterns and consumer demand evolve, so too must automation systems and the teams overseeing them.

Beyond throughput: Building true resilience

Beyond faster operations or lower costs, the biggest value automation provides during periods of global disruption is resilience. When supply chains are unpredictable, companies face the challenge of balancing inventory levels.

AI-powered forecasting tools support this process by predicting demand more accurately, which reduces both shortages and overstock.

Inside the warehouse, integrated management systems add stability by providing a real-time view of parcel movement.

Managers gain visibility into where goods are, how quickly they move and where potential delays may occur. This information allows them to step in early and keep operations on track.

Robotics contributes by working alongside people in daily tasks. Automated systems carry out routine work, while human supervisors guide them and address unusual situations.

This blend of machine consistency and human judgment keeps warehouses operating even when conditions change suddenly.

In this context, automation is a way to equip people with the tools and visibility they need to manage environments that are increasingly complex and volatile.

Looking ahead: Robotics as the new baseline

Global trade will remain uncertain. Whether due to tariffs, geopolitical tensions or supply-demand imbalances, warehouses must prepare for the unexpected. The convergence of AI, robotics and human expertise offers a path forward.

When automation systems amplify human adaptability, warehouses can absorb shocks without losing momentum. This provides a survival strategy for the new era of global commerce.

The market for warehouse automation is growing quickly, with billions of dollars being invested and new AI tools becoming more powerful each year. These advances are setting the stage for automation to become a core part of how supply chains stay resilient in the years ahead.

About the author: Erik Nieves is co-founder and CEO of Plus One Robotics, a software company developing 3D and AI-powered vision software for robots in logistics automation. Prior to Plus One, Erik was technology director for Yaskawa Motoman Robotics where he was responsible for the technology roadmap and emerging applications. During his 25+ year tenure at Yaskawa, Erik held a variety of leadership positions in the US and abroad. Erik serves on the board at Robotics Industries Association (RIA) and is a frequent speaker and contributor to public policy on robotics.