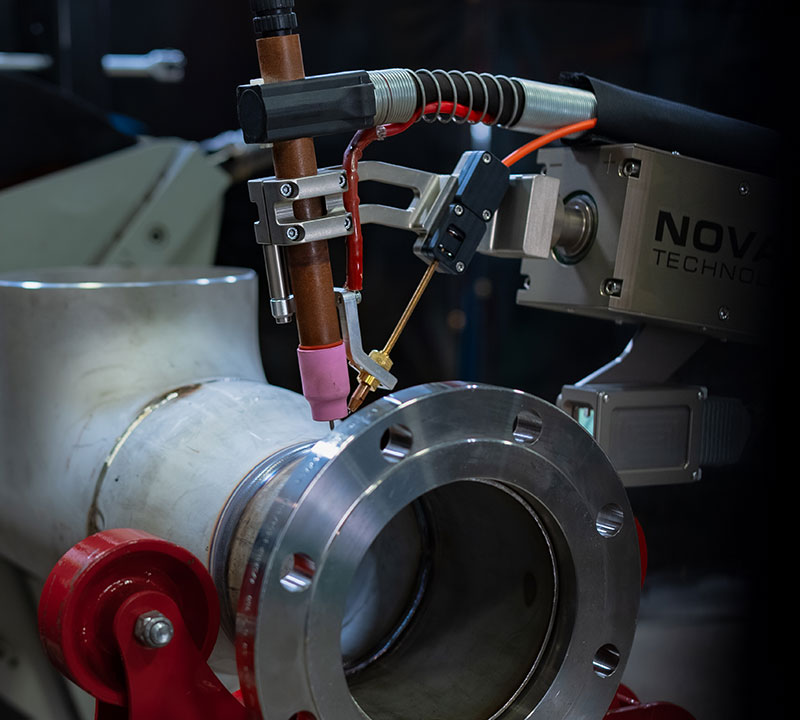

Novarc Technologies, a full-stack AI robotics company pioneering automated welding solutions, has launched its “SWR+TIPTIG Autonomy” system, enabling the performance of high-precision TIG (Tungsten Inert Gas) welding, with no operator and fully autonomous welding.

Designed for fabricators who demand X-ray-quality TIG root welds with the speed and throughput of MIG, the SWR™+TIGMIG Autonomy sets a new standard for productivity and versatility in the pipe fabrication industry.

SWR+TIPTIG Autonomy will be unveiled at Schweissen & Schneiden 2025 in Essen, September 15-19 at Novarc’s booth #3C24.

Soroush Karimzadeh, CEO, Novarc Technologies, says: “Novarc’s new SWR+TIPTIG Autonomy promises to solve challenges being voiced by multiple industry players.

“It elevates existing TIPTIG capabilities to new heights, made possible by SWR+TIPTIG’s continuous evolution, which has been driven by Novarc’s artificial intelligence and machine learning technologies.”

“SWR+TIPTIG Autonomy is the industry’s most versatile Autonomous Welding Robot and the world’s first in full autonomy for the TIG weld process with zero operator intervention for producing X-ray quality welds. Once SWR+TIPTIG Autonomy is set up, operators can just hit start, and move on to set up the next weld,” says Karimzadeh.

SWR+TIPTIG Autonomy results in higher deposition rates with a 2.6x increase in weld deposition and up to 4 lbs/hour in deposition rates, with an increase of up to 300 per cent in travel speeds, surpassing conventional TIG systems.

TIPTIG’s precision also minimizes spatter, oxidation, and discoloration, producing welds that meet hygienic standards without excessive post-weld cleaning.

With the smallest footprint in the industry (4’x4’) and up to 4 positioners, SWR+TIPTIG Autonomy can also maximize both valuable shop space and productivity, benefiting fabricators across a number of industries. Demos of the world’s most advanced TIG welding system are available at Novarc’s booth.