Have you ever wondered how intricate automobile parts like starter motor brackets, flywheel, solenoid valves, and the likes are produced?

Or, perhaps, the massive machine and equipment parts?

How about those Hot Wheels toy car collections that kids love? The answer: die casting.

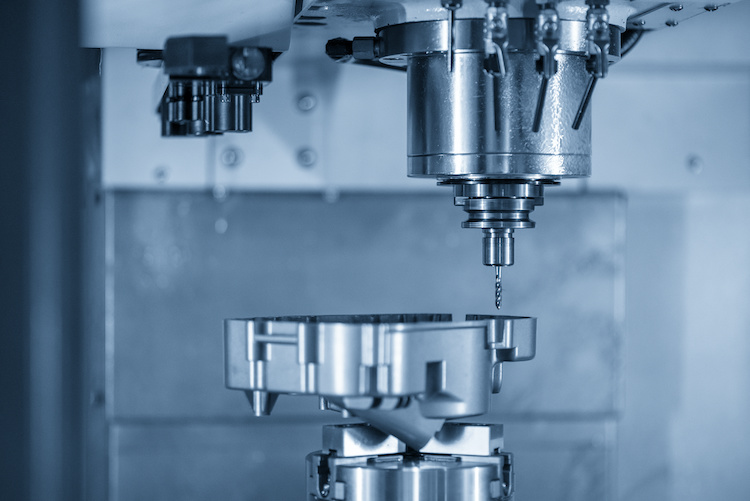

Die casting is an industrial manufacturing process that uses tool dies, which produce metal parts that are too geometrically complex to be produced by any other means.

This process makes use of molten alloy or metal injected into a die at high pressure, which is exactly what Chicago White Metal Castings does.

Die Casting Process

In the process of die casting, the reusable steel molds are being preheated and eventually coated with a die-release agent to protect the dies’ surfaces and lubricate them prior to each use. Molten metals are pre-measured and injected into these dies using very high pressure.

After forming, the newly-formed metal cast will be removed from the dies. This cycle is continuously done over and over whenever a die cools.

This high-pressure process yields dense, fine-grain surface structure with a wide range of both physical and mechanical characteristics like fatigue strength.

Choosing the metals or alloys to be used also depends on the same characteristics: physical and mechanical. One of the most widely used processes is aluminum die casting, although other metals can also be used like brass, magnesium, and zinc alloys.

What are The Advantages of Die Casting?

Die casting can be more applicable to your metal casting needs as compared to other processes. Consider the following advantages.

1. Perfect for Rapid and Mass Production

The dies can be engineered to fabricate different complex but accurate shapes since they are produced through the use of die-casting molds. Because of these casting molds, the process can be repeated several thousand times to create perfectly identical metal casts.

This makes die casting appropriate for mass production. What’s more, is that it’s so convenient because it needs little to no machining at all.

2. Durable, Accurate, and Stable

The dies are expected to be stronger than those you use in the molding process to be able to hold out against the extremely high-pressure injections. They are also heat-resistant and dimensionally stable while they maintain close tolerances.

Diecasts are known to have a higher degree of permanence when loaded compared to their counterparts.

These are way better than a lot of metal mass productions available, like, say plastic moldings, which can be vulnerable to heat and may be affected by weathering, stress cracking, and ultra-violet rays.

3. Strong and Lightweight

Diecasts, even those that are thin-walled, have strengths that are better than their plastic counterparts having the exact same measurements or dimensions. Also, due to the fact that diecasts are one whole piece and not an assembly of different parts, you can expect it to be stronger.

They rely on the strength of the metal of the alloy instead of the durability of how the parts hold together through the joining procedure employed during production.

4. Can Be Made Into Different Texture and Thinness

Since you can do just about any shapes and finishes to the die casting molds, the die-cast parts can be made into textured, smooth, or any variety of surface finishes, depending on the need. Due to this, they can be smoother than some other casting forms like permanent and sand mold.

They can also be made into thinner walls, which can still be as durable, the dimensional limits can be within dimensional limits, or even closer can have holes that are cored to their sizes, among others features.

5. Straightforward Assembly

Die castings can produce fundamental fastening components like studs and bosses, which makes the process more economical, than, say, sand casting. Since almost no machining is required, finishing costs are minimal, which contributes to the overall savings from the process.

They can also require a lesser assembling process, and a die casting can often take the place of several parts. This results in lesser time fabricating a whole new unit of products or assembly.

Parting Words

From the invention of the first die casting equipment in 1839, the process of die casting has gone a very long way in terms of benefits to different industrial and mechanical usage.

Also, what was first made for the purpose of creating parts for printing has developed into machines that serve various requirements that provide convenience.

Although a more advanced form of die casting has been launched, the conventional die casting is still widely used up to this day. At the rate things are going, it looks like this process is still going to be useful for a very long time and has not shown signs of slowing down.

Promoted