Promoted

The effective use of robotics is now prevalent in many types of manufacturing and industrial applications, and metal finishing is no different.

Robots can perform many of the tasks conducted by humans, and they can usually complete them a lot faster and with fewer glitches.

As the execution of robotics-based metal finishing processes creates the need for substantially advanced budgeting, companies usually experience a fast return on investment in the form of increased operating efficiency and lower cost.

Types of metal finishing systems ideal for robotics

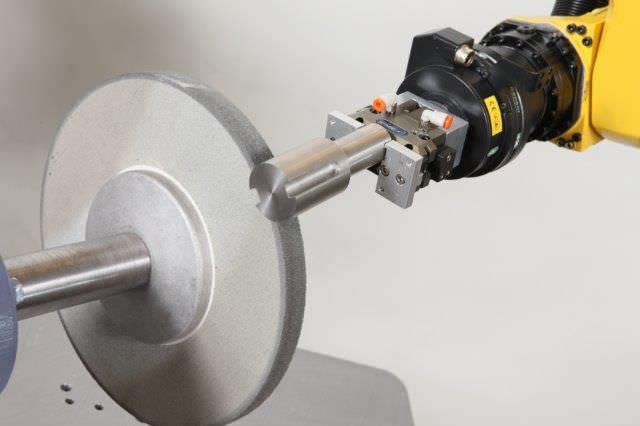

Robotic techniques are now commonly used in processes for example sanding, edge-breaking (deburring), grinding and polishing.

Automated work cells enable computerised processes to eradicate sharp edges, fins, burrs, and various other surface flaws over much shorter periods which is far quicker than human labour.

Most of these work cells can easily be incorporated at the particular point of manufacturing with various other processes and systems that are already in place.

The majority of mass finishing systems I have noticed so far utilise a large vibratory tumbler (click this link for more information about tumbling media used in machines) inside of which a finishing media whirl around which comes in contact with each other and mishmash of workpieces, helping to clean, deburr, polish or smooth the workpieces.

Types of robotic finishing systems

There are specific types of robotic finishing models that are already in use. Included in this are:

Lean finishing cells

Most of these robotic techniques can easily be reinforced by hand tools for the particular high-precision performance of functions for example sanding, edge-breaking, buffing and belting. Some systems also include solutions, for example, outfeed / infeed conveyor straps and fine buffing of delicate components.

High-pressure water edge-breaking systems

These types of systems are efficient enough to generate blasts of water at up to 12,000 pounds per square inch that can efficiently eradicate various kinds of surface flaws.

They are ultimately best for cases where high-precision edge-breaking becomes necessary. The standard use for high-pressure water edge breaking machines include foundry work, die casting, automotive remanufacturing, and others.

Blast cabinets

These systems are ultimately designed for parts featuring difficult geometrical patterns and requiring compliance for demanding quality benchmarks.

The medical devices, automotive and aerospace industries can make the most of blast cabinets.

Benefits of blast cabinets include a higher level of regularity of surface finishes through effortlessly repeatable outcomes and the fairly small size that can save space.

Some great benefits of robotics in metal finishing

With regards to robotics in finishing, you can reap some benefits in a number of ways:

- High-precision edge-breaking, grinding, polishing, and so forth.

- Considerable labour cost savings over time

- Increased customer happiness due to faster job completion times and much fewer product imperfections

- Longer working hours without exhaustion than humans

- Improved safe practices through less human involvement, which can also result in lower insurance rates

- Improved consistency and uniformity

Robotic grinding and polishing

Polishing, de-burring, and grinding manufacturing process in the finishing industry should meet higher anticipations of the high, consistent precision result. Flexibility is important.

From high to low volumes and capable of conforming to different part shapes and demanded finish, these types of systems should always be economical.

The robot software advises the workpieces to process a media in pre-programmed motions such as different immersion depths, defined treatment angles, and circular motion to empower the specific finishing of some surface areas.

Wrapping up

Robotic systems are progressively providing the best methods to all these challenges.

De-burring, polishing and grinding processes can be incorporated with mechanised controlling for automatic feeding, transferring and grasping, load or unload, tool changing and various other related functions.

Automated work cells are produced as an important part of current manufacturing systems, or can easily be self-contained, closed cells by integrating sound and dust protection, providing flexible, compact solutions. Commissioning and installation times can significantly be reduced.

But on the other hand, it is a fact that human labour is drastically reduced in these industries due to the arrival of revolutionary automated and robotics systems as this may change the requirement of human labour and replace it with highly qualified individuals, who can control or conduct the computerised machinery in the finishing industry.