Fanuc has produced half a million robots, and plans to nearly double its robot production capacity in 2018

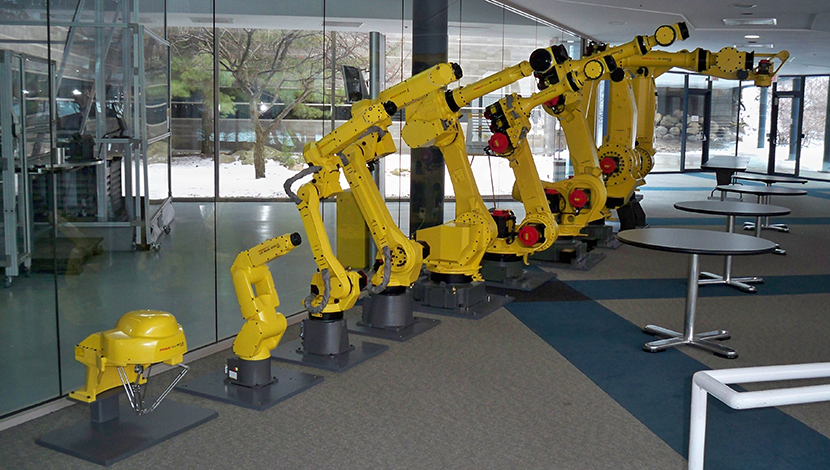

Fanuc, the world’s leading supplier of robotics, CNC and factory automation has announced the production of its 500,000th robot.

Mike Cicco, president and CEO, Fanuc America, says: “Automation and robotics are key drivers of manufacturing competitiveness.

“More companies are using automation to overcome inefficiencies, lower costs, increase productivity, and gain market share.

“Having sold a half million robots is a key milestone for Fanuc, and we’re looking forward to expanding our capabilities to keep pace with the growing demand for automation.”

In April, Fanuc announced plans to build a new factory scheduled to open in August 2018.

Fanuc’s new factory will increase its robot capacity from 6,000 to 11,000 units per month.

“The backbone of Fanuc’s success is our talented workforce – all automation professionals, including an expanding product development team based in Japan and the US.

Cicco adds: “In addition to highly qualified employees, we offer the most reliable automation products in the marketplace.

“Everyone at Fanuc is very motivated and focused on designing the hardware and software that make our products easy to learn and use for all manufacturers, including the practical application of IIoT technologies.”

Recent examples of Fanuc’s latest products include:

The R-30iB Plus controller features a new iPendant with an enhanced screen resolution and processing capability. The user interface, iHMI, has an icon-based screen that provides a familiar and easy-to-use experience with intuitive guides for setup and programming. It also includes tutorials from the main home page that has a design common to Fanuc CNCs, enabling easier use of robots.

The Fanuc Intelligent Edge Link and Drive, or Field, system which provides advanced analytics and deep learning capabilities for Fanuc CNCs and robots, peripheral devices and sensors used in automation systems.

Zero Down Time, or iZDT, an application that runs on the Field system, is built on the four basic building blocks of factory automation:

- mechanical health;

- process health;

- periodic maintenance; and

- system health to prevent unplanned downtime.

It allows monitoring of real-time production information from connected devices, so a customer can take corrective action before any downtime occurs.

As Field system and iZDT grow in the marketplace, Fanuc will be able to help more customers with intelligent condition-based maintenance reminders and help optimize the performance and life of their robots.

MT-Linki shop floor connectivity suite of software. MT-Linki is a fully scalable, out-of-the-box machine tool monitoring solution that can monitor, collect and manage data from one to one thousand machines.

MT-Linki monitors and collects operation and production data using a PC and an Ethernet connection.

The software is set up to automatically collect a variety of data, including alarm history, macro variables and signal history, servo/spindle motor currents and temperatures, battery and fan status, feed rate overrides and more.

The new seven-axis R-1000iA/120F-7B industrial robot has a payload of 120 kg and a maximum reach of 2,230 mm.

The additional axis allows the robot’s J2 arm to fold into itself, making it shorter and able to operate in very tight workspaces.

Fanuc is also leading the effort to address the critical challenge caused by a shortage of skilled workers, and help change the perceptions of careers in manufacturing.

Its Certified Education program provides educators with a STEM-based curriculum centered on robotics and automation training.

Fanuc Cert automation training aligns with industry and national certifications to prepare students for high-tech careers in manufacturing.