How Do Vacuum Pads Work?

Vacuum pads, also known as industrial suction cups, are widely used in a variety of industries for material handling and transportation.

The utilization of vacuum lifting technology through the implementation of vacuum pressure has revolutionized the material handling and transportation industry by providing a safer, more efficient, and cost-effective solution compared to traditional manual lifting techniques.

The use of vacuum pressure to securely hold and lift objects has proven to be a superior method, ensuring the safety of operators and increasing productivity in various industries.

How vacuum pads work:

- Vacuum pads consist of a flexible material, such as rubber or silicone, that is attached to a pump or vacuum generator.

- When the vacuum pressure is applied, the flexible material conforms to the surface of the object being lifted, creating a secure seal.

- The object is then held in place by the vacuum pressure, allowing it to be safely lifted and transported.

- The amount of vacuum pressure used can be adjusted to accommodate different weights and sizes of objects, and the flexible material of the vacuum pad can be designed to adapt to different shapes and surface contours for a more secure grip.

Advantages of using vacuum pads:

- Safe and efficient material handling: vacuum lifting technology eliminates the need for manual lifting, reducing the risk of injury and increasing productivity.

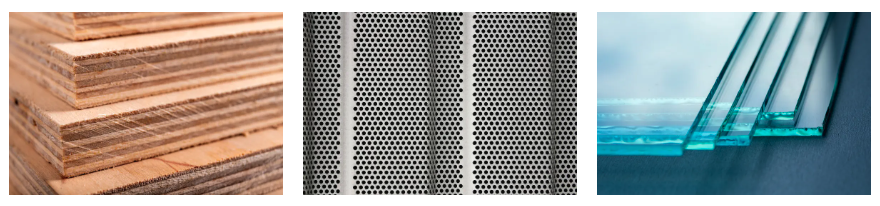

- Versatility: vacuum pads can be used to lift a wide variety of objects, including flat, round, or irregularly shaped items.

- Cost-effective: vacuum lifting systems are typically more cost-effective than traditional manual lifting methods, especially for larger or repetitive lifting tasks.

- Increased efficiency: the use of vacuum pads can greatly increase efficiency by reducing downtime and manual handling errors.

Applications of vacuum pads:

- Material handling: Industries such as construction, packaging, and assembly operations frequently utilize vacuum pads for material handling.

- Automotive manufacturing: Vacuum seals are frequently employed in automotive manufacturing for tasks such as panel handling, paint shop processes, and body shop operations.

- Glass handling: The glass industry often utilizes vacuum pads for handling large glass panels and windshields.

- Woodworking: Woodworking industry uses vacuum pads for lifting and positioning large wooden panels for operations such as sawing, drilling, or routing.

- Stone handling: Vacuum pads are used in the stone handling industry to safely lift and transport heavy stone or marble slabs.

Difference between suction plates and vacuum pads

Suction plates and suction cups are both utilized in material handling and transportation. However, they differ in terms of size, rigidity, and design.

Suction plates are typically larger and more rigid, often made of rubber vulcanized with metal or plastic, and used for the transportation of flat, heavy objects such as sheets of glass or metal plates.

Suction cups, on the other hand, are smaller and more flexible, usually made of rubber or silicone, and are designed to lift and transport smaller and lighter objects like containers or jars.

The choice between suction plates and suction cups will depend on the requirements of the material handling operation.

Both utilize vacuum pressure to secure the material being handled, but their design and function are tailored to the specific needs of the material being transported.

The utilization of vacuum pressure in both suction plates and suction cups ensures a safe, efficient, and cost-effective alternative to traditional manual lifting methods.

Level of vacuum and the size of vacuum pads

In practical application, it is commonly observed that most surfaces requiring suction are not airtight, presenting challenges for vacuum lifting.

The porosity of the material or the roughness of the surface may lead to air leaks into the vacuum through the material or along the edges of the suction pad.

To address this issue and maintain gripping, it is necessary to maintain a high flow of vacuum, compensating for air leakage and ensuring a consistent firm grip. This can be achieved in an economical and efficient manner, even at a low level of vacuum.

It is important to distinguish between two distinct zones within the recommended vacuum range of 35 percent to 80 percent. The choice of the appropriate zone depends on the nature of the object to be gripped and its specific requirements.

EUROTECH vacuum pads solution provider

In summary, vacuum pads (industrial suction cups) are a valuable tool in industries for material handling and transportation. They provide a safer, more efficient, and cost-effective solution compared to manual lifting methods.

Vacuum pads have a flexible material attached to a vacuum generator that creates a secure seal with the object being lifted when vacuum pressure is applied.

Suction plates and suction cups are also used in material handling, each designed for specific needs. The level of vacuum and size of vacuum pads should be considered to ensure a consistent and firm grip, taking into account the material’s porosity and surface roughness.

Vacuum pads are a valuable asset for industries, offering a safe and efficient way to handle and transport materials.

Contact EUROTECH for more information.