Adapting Robotic Production Lines for a Titanium-Focused Economy

With the post-pandemic recovery well on its way, the new jobs market has placed a clear focus on hygiene.

According to CNBC, 66 percent of workers want cleaner, even sterile, working conditions, and that’s independent of their industry. Creating the tools and surfaces required to meet this demand will fall on factories and robotic, or automated, machining.

In turn, this will require innovation to work with materials that are conducive to that sterile environment – which poses a challenge to manufacturers and their robotic factory lines.

The good news is that many of the materials that will lend themselves to a sterile workplace are ones already familiar with the industrial scene.

Deploying titanium

The need for clean surfaces has seen a resurgence in the demand for titanium, both solid and in oxide forms.

Studies have shown that the use of titanium particles can lend an antimicrobial property to surfaces, including one 2021 study published in the journal of Materials Science and Engineering.

The inclusion of titanium block in metal surfaces will enable workplaces to be cleaner – including on the factory floor where it was cut. Titanium is, of course, incredibly strong; stronger than steel yet lighter, and twice as strong as aluminium.

The disability surge

Today, 1 in 4 Americans live with disability, and this number is only increasing according to the CDC.

Largely due to the pandemic, and the fact that long-term Covid is not fully understood, Americans are likely to be dealing with the challenge of disability-causing conditions for years to come.

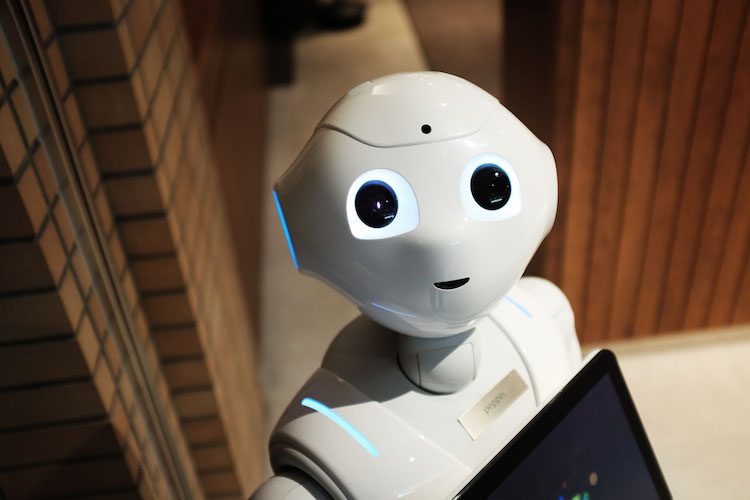

Again, this includes the importance of robot machining. The speed, or alacrity, with which robot-controlled automated lines can produce medical devices, is crucial.

In tandem with titanium, which has sterile and antimicrobial properties that make it absolutely perfect for the purpose of the likes of prosthetics, this will create a factory line for new medical devices to help support a population facing new medical challenges.

Clean and sustainable travel

One of the most heavily impacted areas of the economy has been travel. Flight is an almost uniquely contaminant-ridden form of travel, as well as contributing negatively to climate change.

As Boeing highlights, there has been a long search for better titanium alloys for use in flight, both for environmental reasons and for hygiene; the use of titanium plates inside the aircraft will help to produce antimicrobial results for passengers.

In the factories and manufacturing plants of the world, more demand will once again arise for the need for finely tooled products. With the rush towards more environmentally friendly travel, the need for expediency in production will only become more pressing.

To that end, robot-powered factories and production lines will have a big part to play in the new economy. Titanium is a fantastic resource, and it will see more and more use across the world.

Automated lines must be prepared for this, in terms of schematics, tooling and adaptability, in order to produce the devices needed.